5-48 Chadwick-Helmuth A Business Unit of Honeywell International, Inc.

Chapter 5 - Maintenance And Repair

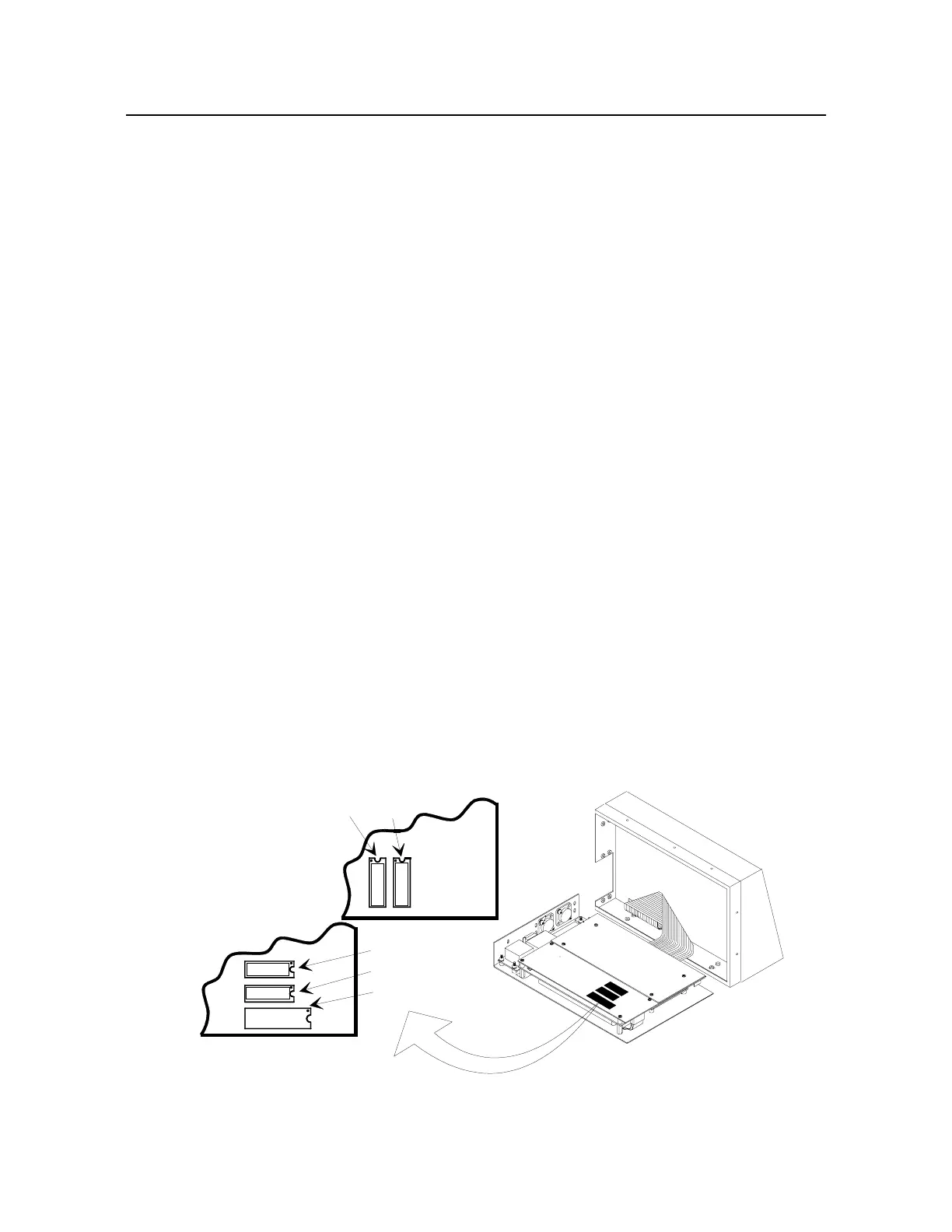

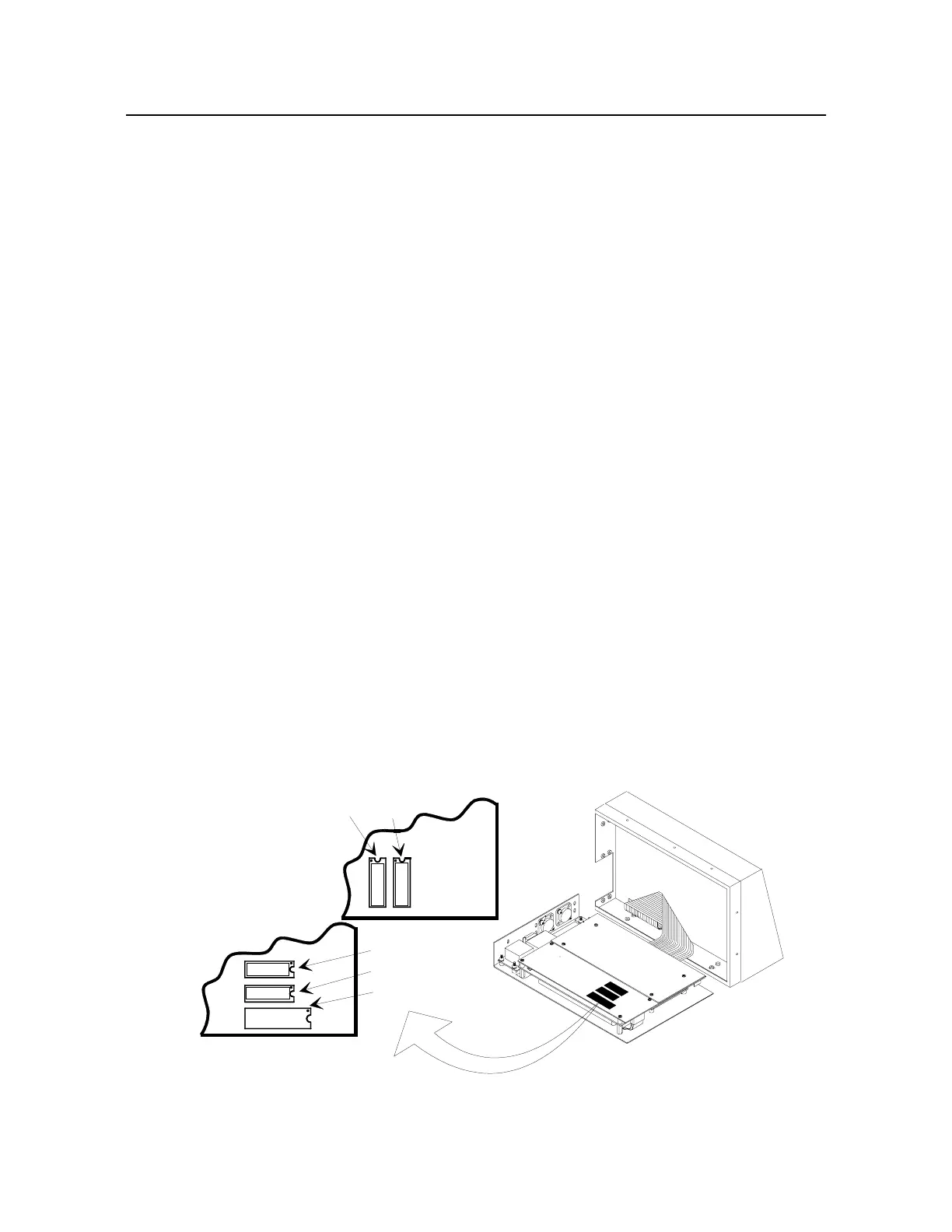

5.7.3 EPROM Change Procedure (Figure 5-15)

NOTE: The firmware in the 8500C+ is changed through a programming disk and does not

require the unit to be opened. The EPROMS are shown here in the event the device fails.

This procedure is for changing EPROM’s (U8) and (U9) on the digital board (A1) of the balancer/

analyzer assembly. The program code (“firmware”) that operates the unit is contained in these

EPROM’s, so over the life of the 8500C balancer/analyzer, this part may be changed several times as

features are added.

This procedure is best performed by a qualified electronics technician, but if the procedure is followed

precisely and with care, it can be done by any person generally familiar with electronic equipment.

Precautions against a static discharge to the EPROM are the most critical part of this procedure.

5.7.3.1 Preparation

Prepare a static-free work area. If you don’t have access to a static-free work station with a grounded,

conductive table top and a grounded wrist strap, the following will suffice.

On a normal wood or plastic table top, cover a one-half to one-meter-square area with aluminum foil

taped down at the edges. Touch the foil with your bare hand and set the 8500C balancer/analyzer and

the EPROM container on the foil. During the entire procedure, do not grab any materials not in contact

with the foil, especially sheets of paper or plastic. During the entire procedure, keep your skin in

contact with the foil by leaning on a bare elbow.

Tools required: one small Phillips-head screwdriver and one small straight-blade screwdriver.

5.7.3.2 Procedure

a. Remove ten screws (Figure 5-17, (32)) and four screws (33) and remove bezel (4).

b. Fold back printer/disk drive assembly so that it stands straight up on its side with keypad

panel (1) lying flat on table. With unit in this position, 2 EPROM’s (Figure 5-15, (U8) and

(U9)) are accessible on face-up side of digital board A1 (Figure 5-17). A paper label

covers center portion of each EPROM. Label for (U8) is stamped with P/N 10927-X and

(U9) is stamped with P/N 10928-X.

Figure 5-15. EPROM Locations on Digital Board

U10

U9

U8

DIGITAL BOARD A1

NOTE: NOTCHED ENDS ON EPROMS MUST BE IN DIRECTION SHOWN. LEFT ENDS OF EPROMS U8 & U9 MUST

BE ALIGNED WITH U10. U8 & U9 MAY DIFFER IN SIZE.

FILE: EPROMSA.DS4

10927-X

10928-X

U9

U6

8500C

8500C+

+

Loading...

Loading...