8-6

8.3 Reassembling the Detector

1. Align the PCB at the top rear of the main

chassis with the connector located at the top

of the mounting bracket assembly.

2. At the same time align the two tubes at the

bottom rear of the main chassis with the two

tubes located on the bottom of the mounting

bracket assembly.

3. Slide the chassis backwards on the mounting

bracket assembly so that the PCB, connector

and tubes engage simultaneously.

4. Ensure the PCB, connector and tubes are fully

engaged by firmly pushing the main chassis

horizontally backwards on the mounting bracket

assembly.

(WARNING: DO NOT PUSH ON THE LCD AS

THIS MAY CAUSE DAMAGE).

5. Align the two attaching screws located at the

bottom of the chassis with the screw threads

on the mounting bracket assembly.

6. Tighten the screws to secure the chassis to

the mounting bracket assembly.

7. Switch the power switch on the terminal

module to the ‘on’ position.

8. Refit the detector’s cover by aligning the

slots either side with the locating tabs on the

mounting bracket assembly.

9. Push the cover horizontally until home.

10. Tighten the thumbscrew located on the front

panel.

Note

Honeywell Analytics recommends

conducting a “Flow Calibration” (See

Section 7.3 for instructions)

8.4 Filter Replacement

The internal filter (MIDAS-A-009) has been designed

for easy replacement.

The following procedure should be followed carefully

and only performed by suitably trained personnel.

1. Isolate the power to the detector.

2. Unscrew the thumbscrew located on the front

panel.

3. Remove the cover by pulling it forwards off the

main chassis.

4. Unscrew the two retaining screws located at

the bottom front of the chassis.

5. Pull the main chassis forward to disconnect it

from the mounting bracket assembly.

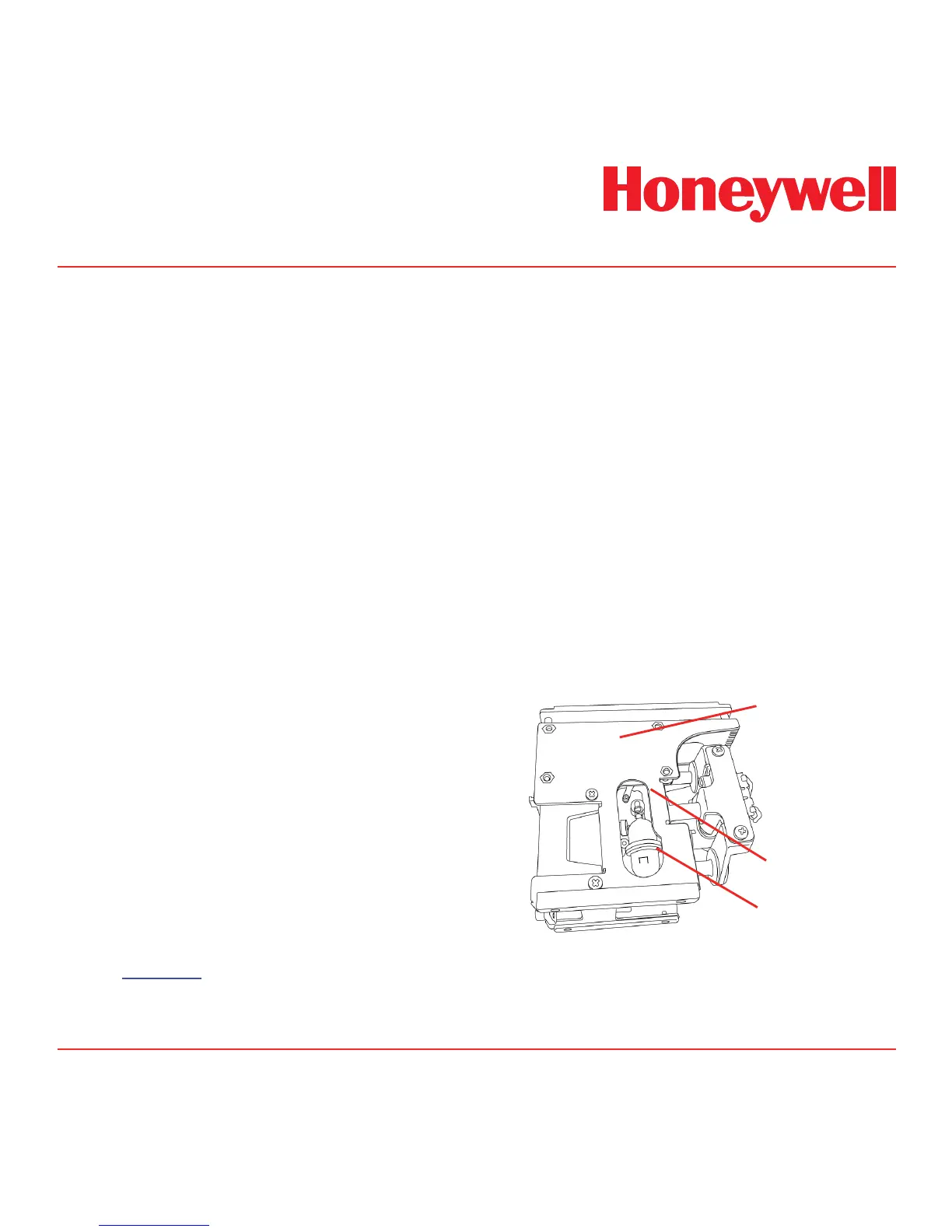

6. Locate the filter access slot in the side of the

main chassis.

Diagram 8-6. Filter location.

Main chassis

Filter

Filter access slot

7. Carefully disconnect both sides of the filter

from the pump manifold.

8. Remove the old filter and replace with a new

Loading...

Loading...