LP-605 Rev. 000 Rel. 009 Date 8.16.18

27

E. Exhaust Vent and Intake Pipe Sizing

1. The exhaust vent and intake pipe adapters are 3”.

2. The total equivalent length of 3” exhaust vent and intake pipe

should not exceed one hundred (100) feet (30m).

a. The equivalent length of elbows, tees, and other ttings are

listed in the Friction Loss Table.

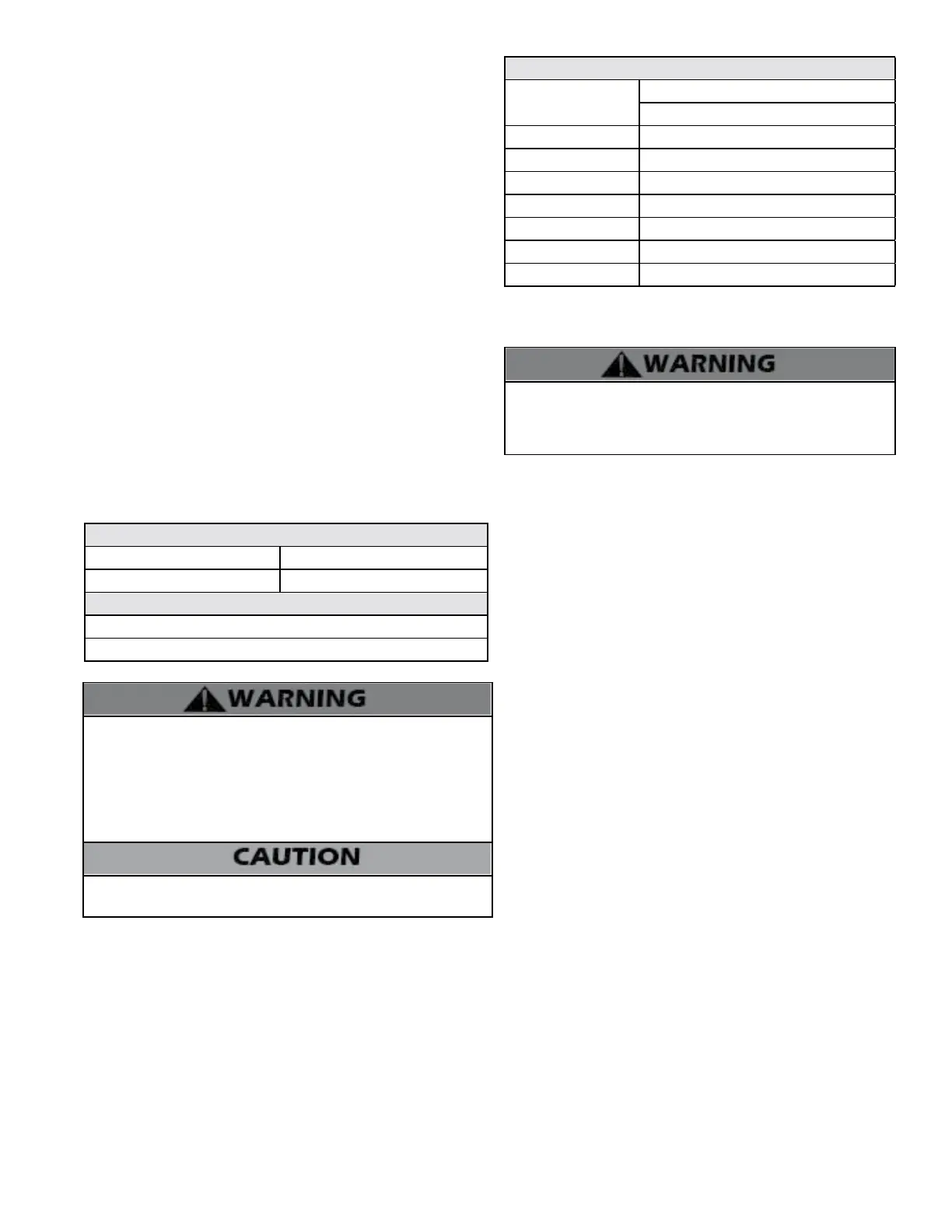

Friction Loss Equivalent in Piping and Fittings

Fittings or Piping

Equivalent Feet

3”

90 Degree Elbow 5’ (1.5m)

45 Degree Elbow 3’ (0.9m)

Coupling 0’

Air Inlet Tee 0’

Straight Pipe 1’ (0.3m)

Concentric Kit 3’ (0.9m)

V1000 3” Kit 1’ (0.3m)

Table 10 - NOTE: Consult Polypropylene venting instructions for friction

loss and pressure drop equivalents.

b. For example: If the exhaust vent has two 90

o

elbows and 10 feet

of PVC pipe we will calculate:

Exhaust Vent Equivalent Length = (2x5) + 10 = 20 feet.

Further, if the intake pipe has two 90

o

elbows, one 45

o

elbow, and

10 feet of PVC pipe, the following calculation applies:

Intake Pipe Equivalent Length = (2x5) + 3 + 10 = 23 feet.

Finally, if a concentric kit is used we nd:

Total Equivalent Length = 20 + 23 + 3 = 46 feet.

The total equivalent length is 46 feet, well below the maximum of

150 feet.

c. Eort should be made to keep a minimum dierence in

equivalent length between the exhaust vent and intake pipe.

Vent adaptors are not designed as load-bearing devices, and must

not be used to support exhaust vent piping. All vent pipes must be

properly connected, supported, and the exhaust must be pitched

a minimum of ¼” per foot back to the boiler to allow drainage of

condensate. Failure to properly support vent piping and follow the

information in this statement could result in product damage, severe

personal injury, or death.

3. The minimum total equivalent length is 7 feet (2.1m).

NOTE: The intake pipe and exhaust vent lengths do not have to be of

equal length. There is no balancing requirement between intake and

exhaust.

It is important to ensure an airtight seal from the water heater collar to

the vent terminations. It is EXTREMELY IMPORTANT that the maximum

allowed combined venting lengths are not exceeded. See Table 8

for a list of Approved Vent Materials and Table 11 for Approved Vent

Lengths.

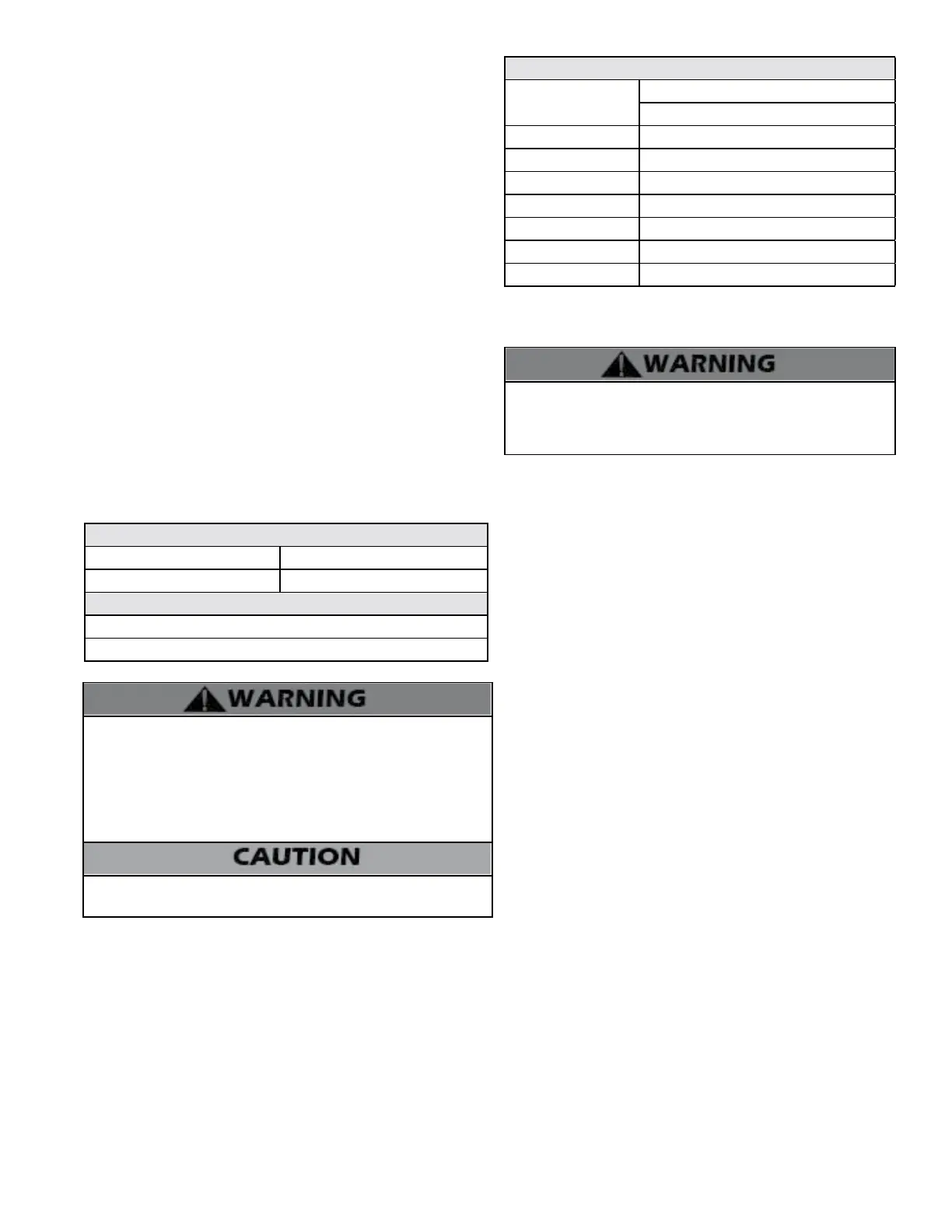

3” Combined Vent Length

Minimum Maximum

7’ (2.1M) 100’ (30M)

Maximum # of 90

o

Elbows

3”

8

Table 11 - Approved Vent Lengths

Failure to provide a minimum total vent length of 7 equivalent feet

could result in property damage and improper appliance operation.

G. Exhaust Vent and Intake Pipe Installation

All joints of positive pressure vent systems must be sealed

completely to prevent leakage of ue products into the living

space. Failure to do so could result in property damage, serious

injury, or death.

1. Use only solid PVC or CPVC pipe or a Polypropylene vent system

approved for use with Category IV appliances.

FOAM CORE PIPING IS NOT APPROVED FOR EXHAUST VENT

APPLICATIONS. Foam core piping may be used on air inlet piping

only.

2. Remove all burrs and debris from joints and ttings.

3. When using PVC or CPVC pipe, all joints must be properly cleaned,

primed, and cemented. Use only cement and primer approved for

use with the pipe material. Cement must conform to ASTM D2564

for PVC and ASTM F493 for CPVC pipe. NOTE: DO NOT CEMENT

POLYPROPYLENE PIPE.

4. Ensure the vent is located where it will not be exposed to

prevailing winds.

5. In all roof venting applications, exhaust discharge must point

away from the pitch of the roof.

6. To prevent water leakage, install adequate roof ashing where the

pipe enters the roof.

7. Do not locate vent over public walkways, driveways, or parking

lots. Condensate could drip and freeze, resulting in a slip hazard or

damage to vehicles and machinery.

8. Due to potential moisture build-up, sidewall venting may not

be the preferred venting option. To save time and cost, carefully

consider venting installation and location.

9. Horizontal lengths of exhaust vent must slope back towards the

water heater not less than ¼” per foot to allow condensate to drain

from the vent pipe.

10. The exhaust vent must terminate where vapors cannot make

accidental contact with people or pets, or damage shrubs or plants.

11. In vacant chimney applications, install and seal a rain cap over

existing chimney openings.

12. All piping must be fully supported. Use pipe hangers at a

minimum of 4 foot intervals to prevent sagging of the pipe where

condensate may form.

13. Do not use the heater to support any piping.

14. A screened straight coupling is provided with the heater for use

as an outside exhaust termination.

15. A screened inlet air tee is provided with the heater to be used as

an outside intake termination.

16. Maximum Snow Level Determination: These installation

instructions reference snow levels in establishing a minimum height

for the installation of exhaust vent or air intake terminations. Snow

levels shall be determined as follows:

a. The installation location may, by ordinance, designate how snow

Loading...

Loading...