LP-605 Rev. 000 Rel. 009 Date 8.16.18

38

Part 8 - Gas Connections

FIRE AND/OR EXPLOSION HAZARD

To avoid serious injury or death, the gas line installation and the gas line inlet pressure test must be done by a licensed professional.

Ensure the gas on which the water heater will operate is the same type specied on the rating plate (natural gas or LP gas). This water

heater must be converted into propane operation unless specically manufactured for use with propane. Follow Gas Conversion Manual

instructions (separate document). Propane ready water heaters have the sux “LP” after the model serial number. Failure to follow these

instructions could result in property damage, personal injury, or death.

Make sure the gas line pressures are within normal limits. Pressures outside normal limits can result in poor performance and hazardous

operating conditions.

A manual gas control valve (shut-o valve) must be connected to the unit before the gas line.

Check the gas inlet pressure and make sure your gas meter is capable of supplying sucient BTU load to all appliances. Insucient gas

pressure and volume will cause your water heater to be decient in performance and operation.

When connections are completed check for gas leaks by applying soapy water to all gas ttings and connections. Presence of soap bubbles

foaming is a sign of a gas leak.

This water heater and its individual shut-o valve must be isolated from the gas supply piping system by unplugging the unit and turning

o the main gas valve during any pressure testing of the gas supply piping system at test pressures equal to or less than ½ PSI.

Failure to follow these instructions could result in property damage, personal injury, or death.

A. Gas Pipe Sizing Tables

1. Gas Pipe Sizing

This information is for reference use only. Refer to gas pipe manufacturer specications for actual delivery capacity. The DOE standard for

Natural Gas is 1100 BTU/ft

3

. Contact the local gas supplier for actual BTU/ft

3

rating. Size gas piping system by following ANSI Z223.1/NFPA 54

or local codes.

• When measuring the inlet supply pressure, the water heater and all other gas appliances sharing the gas supply line must be ring at

maximum capacity.

• Maximum gas pressure must not exceed listed value.

• Low gas pressure could be caused by an undersized gas pipe. This will cause the water heater’s performance to diminish, limiting the

ability to reach maximum performance.

NOTE: DO NOT USE 1/2” quick ex gas lines! Doing so will result in improper appliance operation.

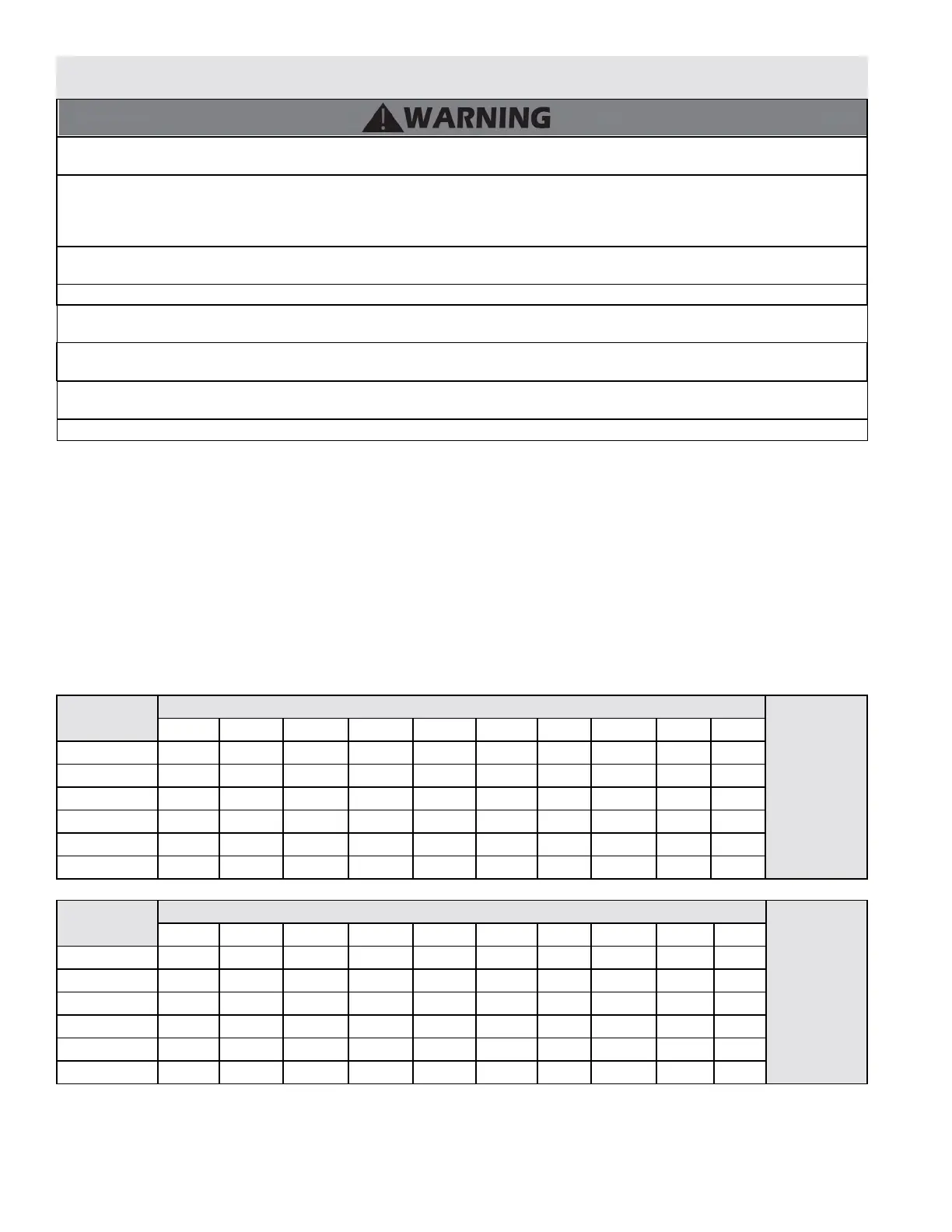

2. Natural Gas Pipe Sizing

The following tables list maximum capacity of pipe in cubic feet of gas per hour for gas pressures of 11” or less and a pressure drop of 0.5

inches water column, based on a 0.60 specic gravity for natural gas.

Pipe Size (in.)

Length of Pipe (Feet)

BTU’s Per

Hour x 1,000

(0.60 Specic

Gravity,

0.5 WC

Pressure Drop)

10 20 30 40 50 60 80 100 150 200

1/2 82 58 47 41 37 37 29 26 20 18

3/4 192 137 112 97 87 80 69 62 48 44

1 383 269 218 188 168 153 132 118 91 82

1 1/4 639 456 374 325 292 267 232 208 171 148

1 1/2 1260 888 723 625 559 509 440 393 320 277

2 2930 2080 1700 1470 1320 1200 1040 933 762 661

Table 19 - Natural Gas Delivery Capacity - Corrugated Stainless Steel Pipe - Refer to ANSI Z223.1 - National Fuel Gas Code, Latest Edition

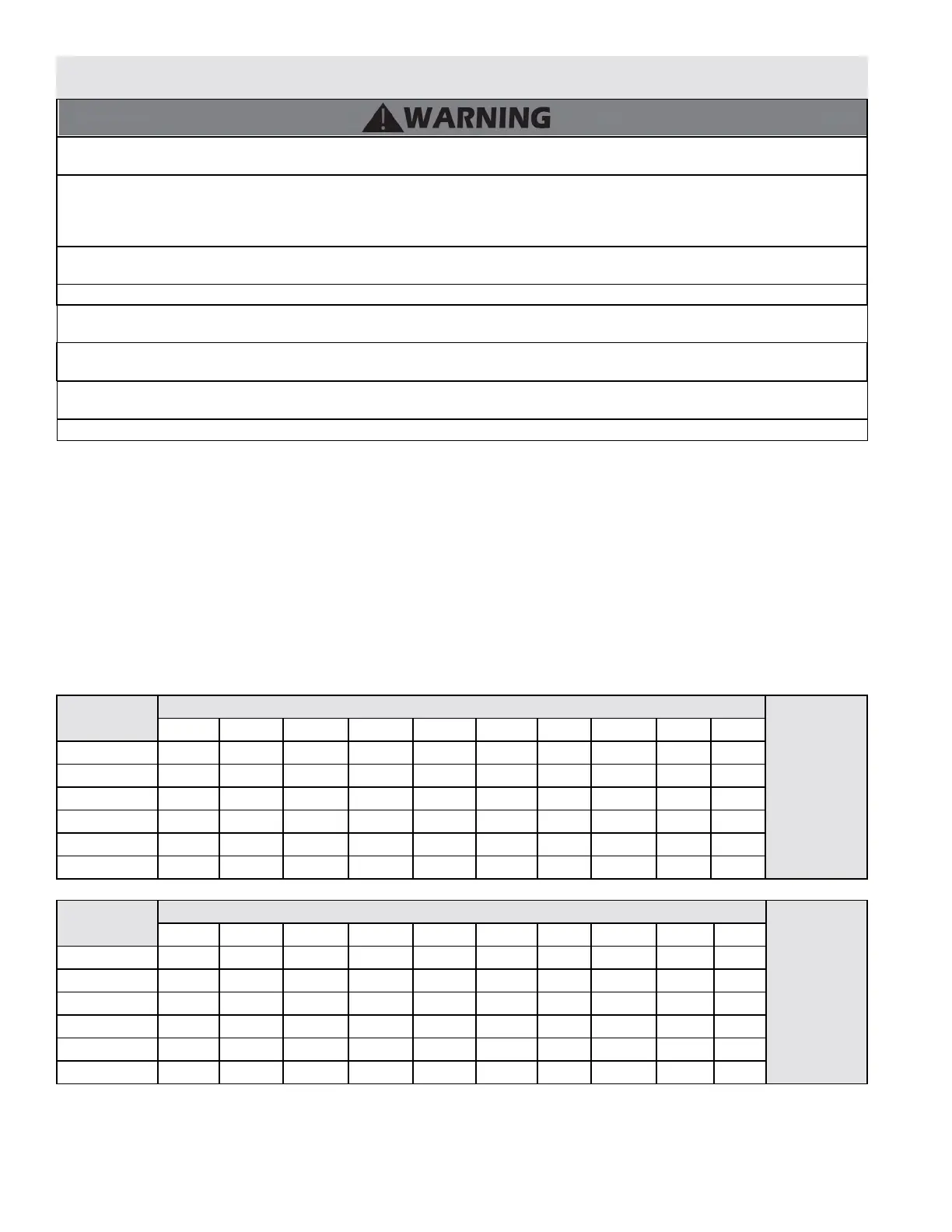

Pipe Size (in.)

Length of Pipe (Feet)

BTU’s Per

Hour x 1,000

(0.60 Specic

Gravity,

0.5 WC

Pressure Drop)

10 20 30 40 50 60 80 100 150 200

1/2 172 118 95 81 72 65 56 50 40 34

3/4 360 247 199 170 151 137 117 104 83 71

1 678 466 374 320 284 257 220 195 157 134

1 1/4 1390 957 768 657 583 528 452 400 322 275

1 1/2 2090 1430 1150 985 873 791 677 600 482 412

2 4020 2760 2220 1900 1680 1520 1300 1160 928 794

Table 20 - Natural Gas Delivery Capacity - Black Iron Pipe - Refer to ANSI Z223.1 - National Fuel Gas Code, Latest Edition

3. LP (Liquid Propane) Gas Pipe Sizing

The following is intended for use for piping between a Single or Second Stage (Low Pressure) Regulator and the water heater. The following

tables list maximum capacity of pipe in cubic feet of gas per hour for an inlet pressure of 14 inches water column and specic pressure drop

of 0.5 inches water column based on 1.5 specic gravity for liquid propane.

Loading...

Loading...