LP-605 Rev. 000 Rel. 009 Date 8.16.18

40

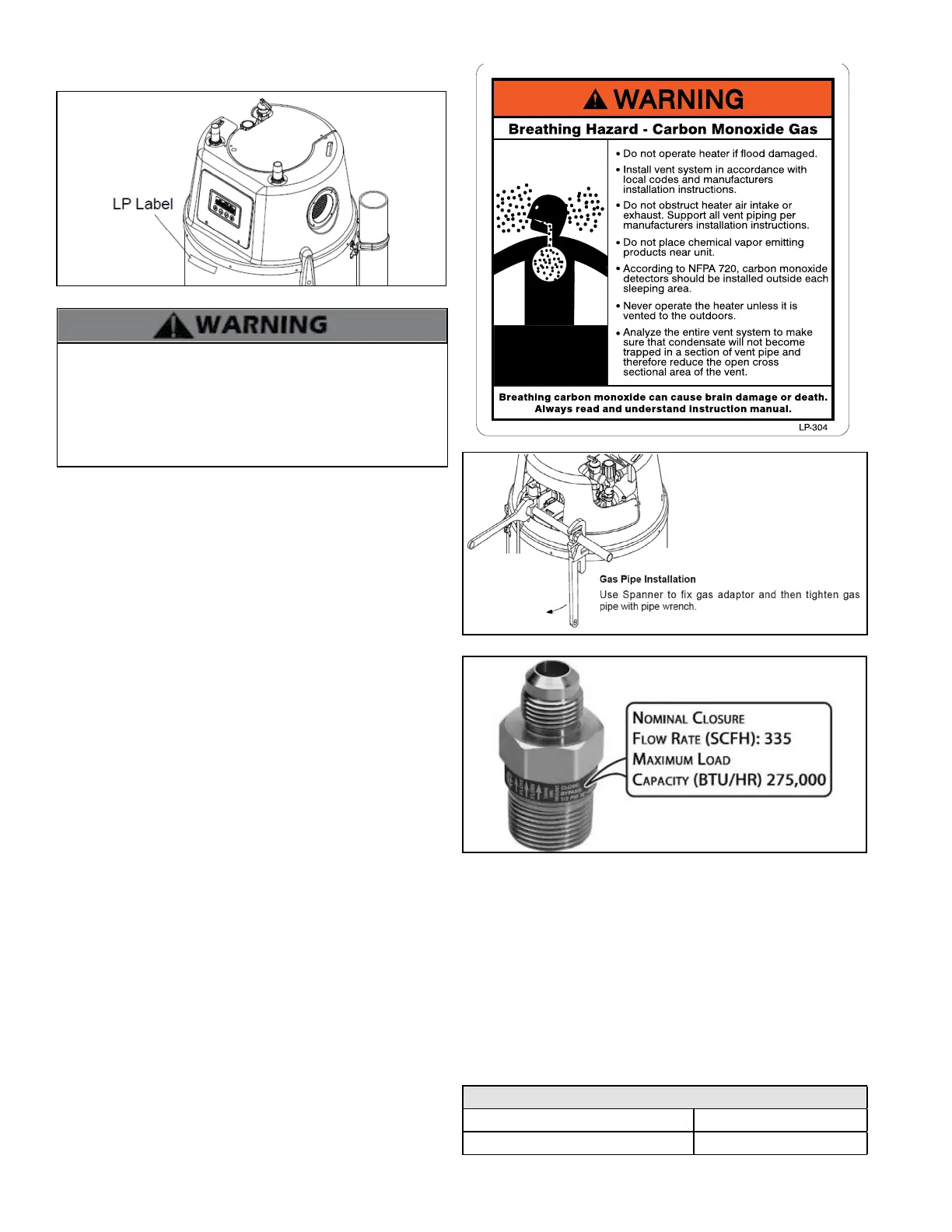

5. Reassemble the top service panel and apply the LP label which is

in the accessory kit.

Figure 42 - Excess Flow Valve (EFV)

Prior to start-up, ensure the unit is set to re on propane. Check

the rating label for the type of fuel. Use a calibrated combustion

analyzer to ensure the CO / CO2 limits are within the limits listed

in Table 24. If there is a conict or doubt on the setup, remove

the gas tube and check for the propane orice. Failure to ensure

proper setup could result in property damage, severe personal

injury, or death.

C. Gas Connection Requirements

1. The gas connection tting on the water heater is ¾” female

NPT. NOTE: A 3/4” X 1/2” reducer is provided with the water

heater for connection to 1/2” gas lines. It is important to

review the gas table to ensure that the gas line is properly

sized for the BTU output of the water heater.

NOTE: DO NOT USE 1/2” quick ex gas lines! Doing so will

result in improper appliance operation.

2. The supply line must be sized for the maximum output of

the water heater being installed. If there are additional gas

appliances from the main supply line, measure the size of

the supply line according to the COMBINED total maximum

BTUH draw for the appliances as if they were operating at

the same time.

3. Measure the length of the gas supply line from the gas

meter to the water heater. Water heater must be installed

downstream of the gas meter to ensure adequate gas

supply. Use the tables in this manual or refer to the gas line

manufacturer’s sizing information to determine the correct

supply pipe size.

4. A manual gas shut-o valve should be installed in the gas

supply line close to the water heater.

5. To facilitate any future maintenance, it is also recommended

that an approved gas union tting be installed in the supply

line between the shut-o valve and the connection on the

water heater.

6. Test the gas pressure to make sure it meets the minimum

standards and does not exceed the maximum standards of

the water heater.

7. Leak test the gas line pipe before placing the water heater in

operation. Only use approved leak detector liquid solutions

to check for leaks.

8. Do not operate the water heater until all connections have

been completed and the heat exchanger is lled with water.

Figure 40 - Reassembled Top Service Panel and Applied LP Label

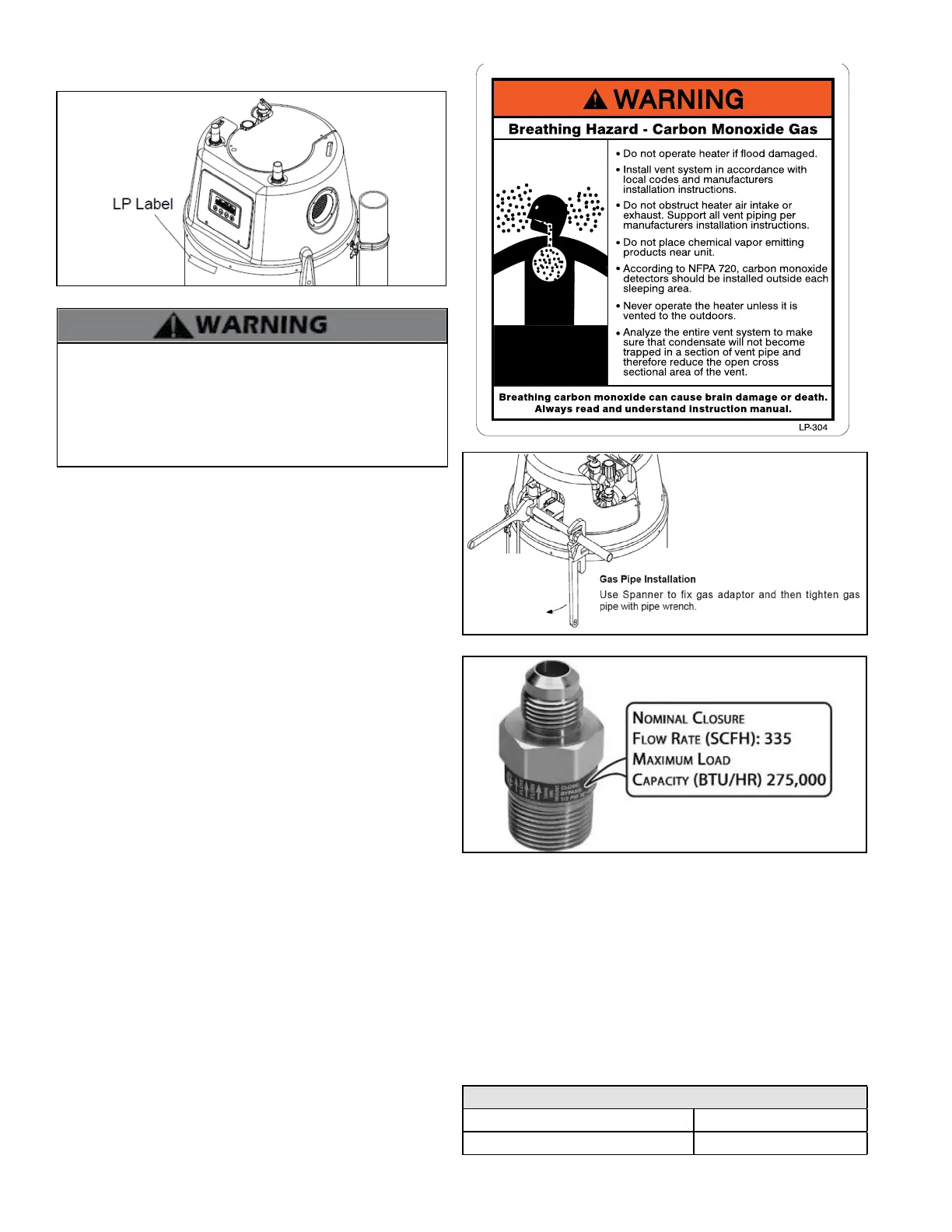

D. Additional Precaution for Excess Flow Valve (EFV)

If an excess ow valve (EFV) is in the gas line, check the manufacturer’s

minimum and maximum ow capacity ratings. An improperly sized

EFV will not allow for a full ow of gas to the water heater and will

cause the water heater to malfunction. See Figure 43.

Figure 41 - Installing the Gas Line to the Water Heater

E. Checking Gas Pressure at the Water Heater

NOTE: Refer Figure 44 when checking gas pressure. Loosen the bolts

before checking the gas inlet pressure.

1. The water heater and its individual shuto valve must be

disconnected from the gas supply piping system during any pressure

testing of the system at test pressures greater than ½ psi (3.5 kPa).

2. The water heater must be isolated from the gas supply piping system

by closing its individual manual shuto valve during any pressure

testing of the gas supply piping system at test pressures equal to or

less than ½ psi (3.5 kPa).

The minimum and maximum inlet gas line pressures must meet the

requirements shown in Table 23.

Natural or LP Gas

Minimum Pressure 3.5” WC

Maximum Pressure 14”WC

Table 23 - Gas Pressure Requirements

Loading...

Loading...