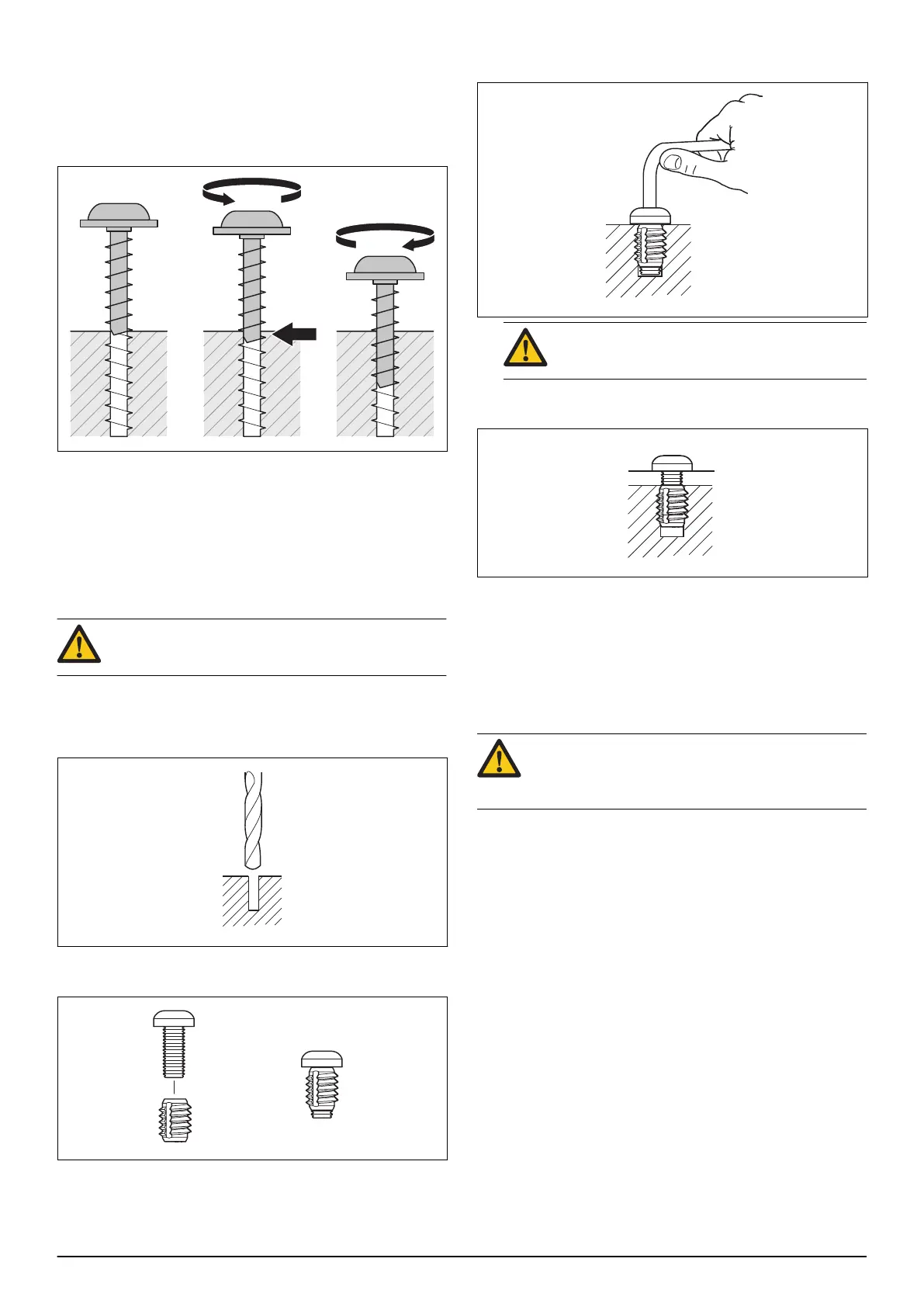

To ensure the threads in plastic parts are not damaged:

1. Carefully turn the screw counter-clockwise until it

engages the existing threads in the plastic. The

screw will fall slightly by itself when the threads are

located correctly in relation to the existing threads in

the plastic.

2. Screw in the screw to the correct torque as specified

in

Screw fasteners on page 43

.

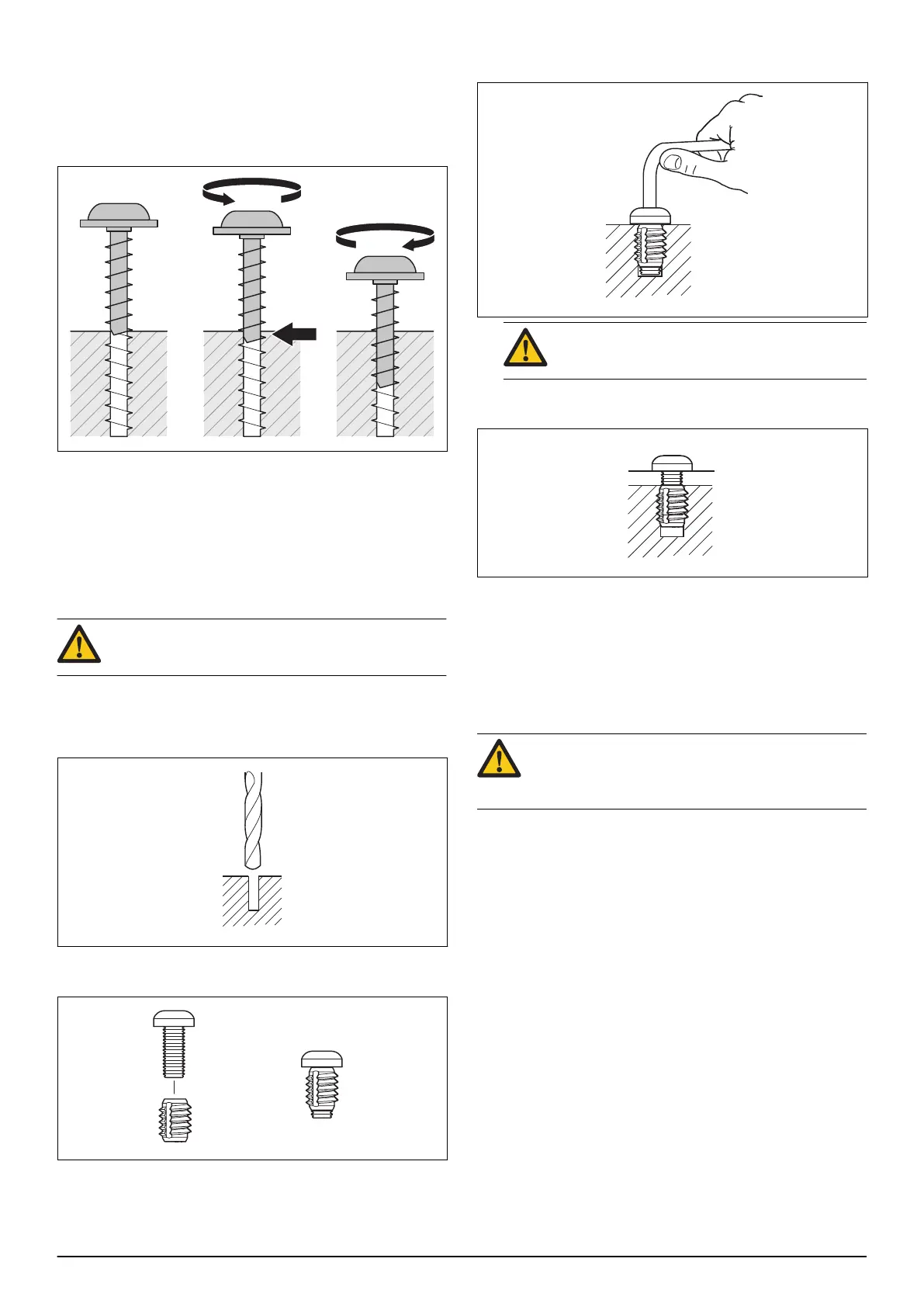

6.24 To mount thread plugs

If the threads in plastic parts are worn, thread plugs can

be inserted. A repair kit containing thread plugs and

suitable metal screws is available to order.

CAUTION: Fit the thread plug carefully since

there is a risk that the screw bosses crack.

To mount a thread plug into a worn plastic thread:

1. Make the hole bigger with a 6.6 mm drill to a depth

corresponding with the plug.

2. Mount the thread plug with the screw that comes

with the repair kit and screwdriver.

3. Make sure the plug is screwed in completely so that

a good seal is obtained.

CAUTION: Tighten by hand so as not to

damage the plastic.

4. Fit the plastic parts with the accompanying screw

instead of the old plastic screw.

6.25 To replace the sealing strips

There are 2 sealing strips between the upper chassis

and lower chassis in the product. One between the

center console and the upper chassis and one between

the lower and upper chassis. Both sealing strips must be

replaced using the same technique.

CAUTION: A 5 mm sealing strip must be used.

Sealing may be deficient if the wrong sealing

strip is used.

1. Start by laying one end of the sealing strip in line

with the marking on the chassis.

2. Continue laying the sealing strip clockwise around

the lower chassis.

40 - Repair instructions 1191 - 001 -

Loading...

Loading...