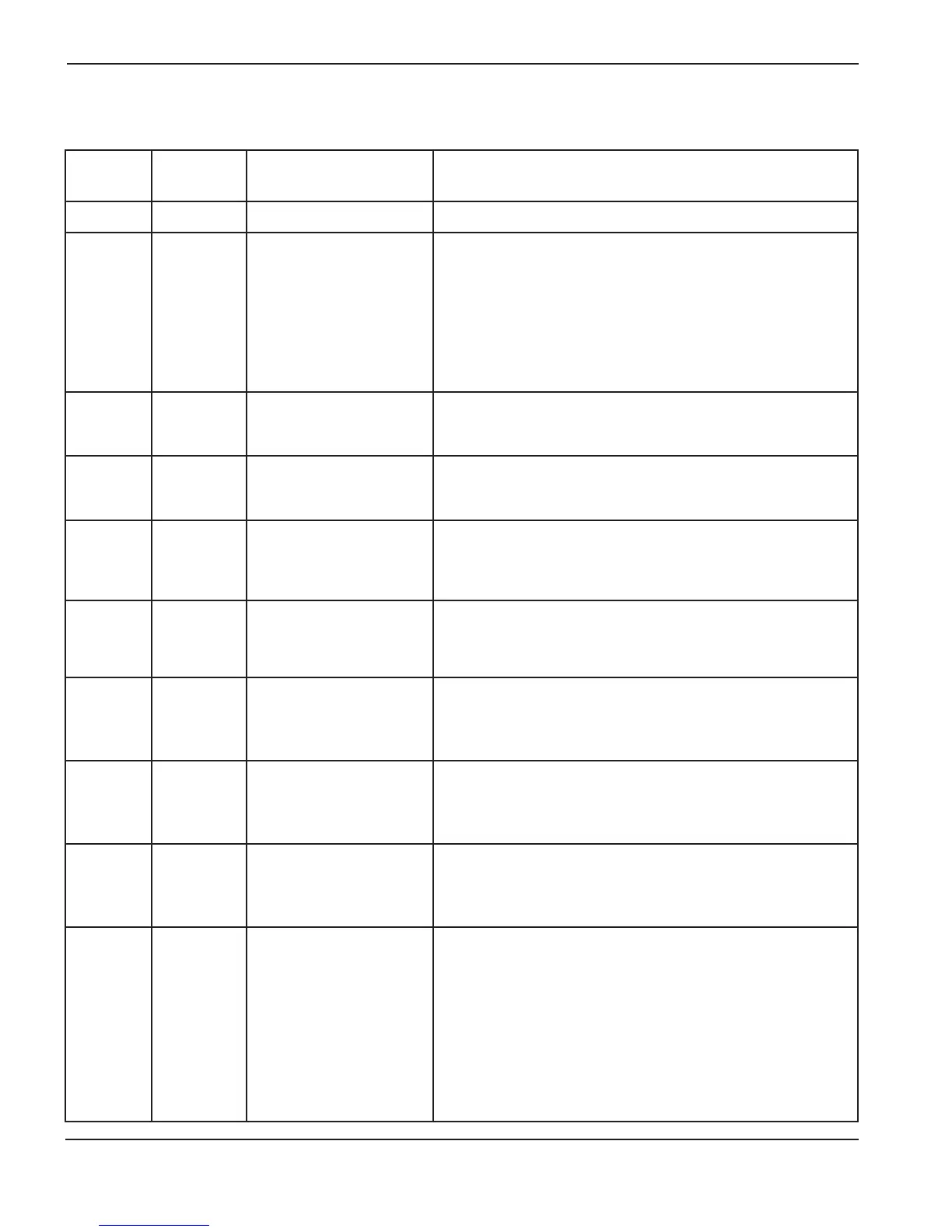

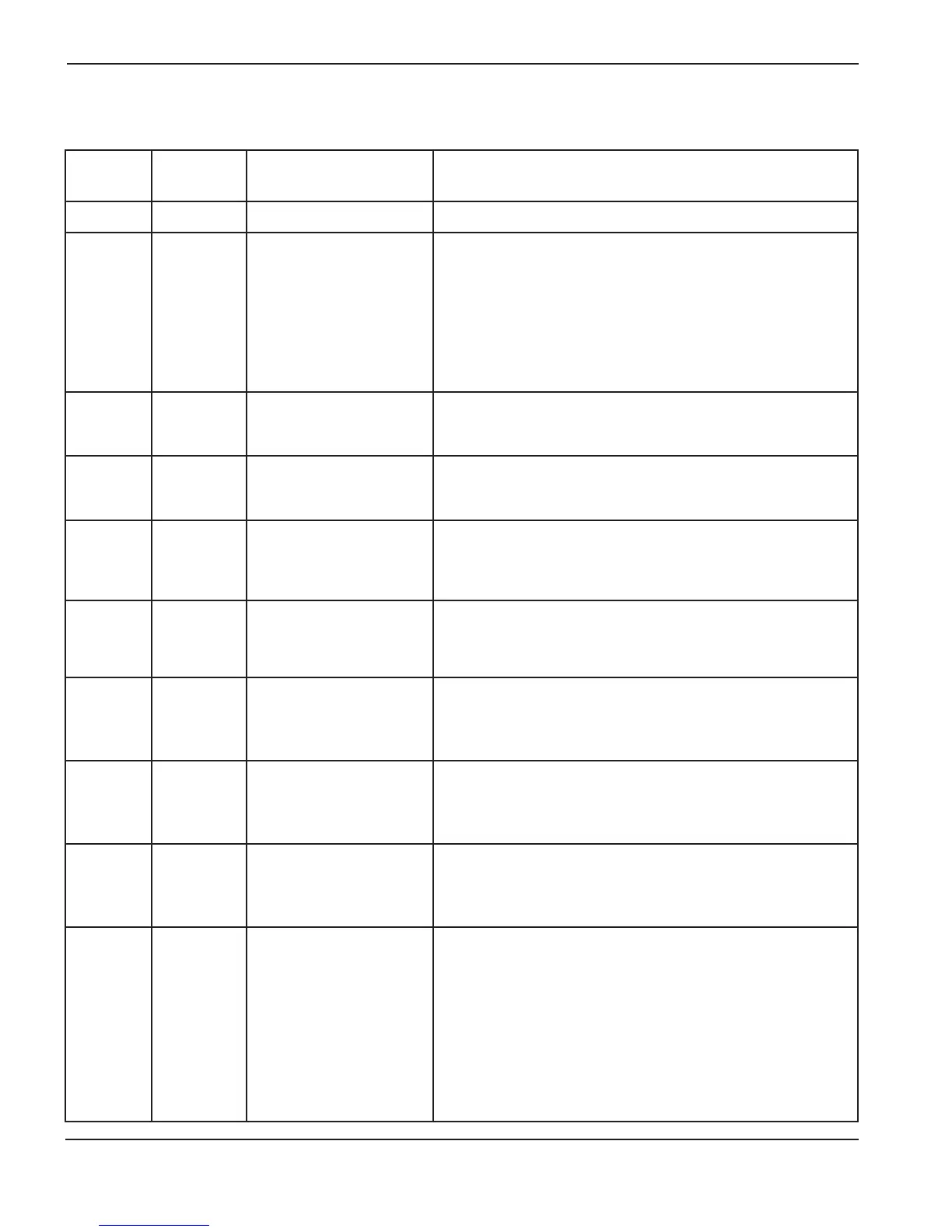

Error code troubleshooting – 1 of 16

Error code

number

Name Description Corrective action

000 No error System is ready to run. None needed.

009

Flow switch

test

The flow switch is tested

when the pump restarts

after a pump timeout

(30 minutes without a start

signal). The test ensures

that the coolant flow is

correct before firing the

torch.

Wait 10 seconds for the flow rate to stabilize.

012

Test in

progress

One of the gas test modes

is running.

Wait for the test to finish.

013 Test passed The test was successful. No action required.

014

Cut gas

channel 1

fail

The gas pressure in

channel 1 is decreasing,

which indicates a leak.

Look for leaks and loose connections between the selection

console and the metering console.

015

Cut gas

channel 2

fail

The gas pressure in

channel 2 is decreasing,

which indicates a leak.

Look for leaks and loose connections between the selection

console and the metering console.

016

Plasma

rampdown

fail

Plasma pressure did not

decrease in the time

allowed

Verify that there is no obstruction in the plasma vent hose.

017

Shield

rampdown

fail

Shield pressure did not

decrease in the time

allowed

Inspect the holes in the shield for obstructions. Replace the

shield if the holes are blocked.

018

Pump over

pressure

HPR260

only

Pump output has

exceeded 15.5 bar

(225 psi).

1. Verify that coolant filters are in good condition.

2. Verify that there are no restrictions in the coolant system.

020 No pilot arc

No current detected from

chopper at ignition and

before 1-second timeout.

1. Verify that the consumable parts are in good condition.

2. Verify proper preflow and cut-flow settings.

3. Perform gas leak tests (see Maintenance section).

4. Verify spark across spark gap.

5. Inspect CON1 and pilot arc relay for excessive wear.

6. Perform gas flow test (see Maintenance section).

7. Perform torch lead test (see Maintenance section).

8. Perform start circuit test (see Maintenance section).

9. Perform chopper test (see Maintenance section).

5-10 HPR400XD Manual Gas Instruction Manual

MAINTENANCE

Loading...

Loading...