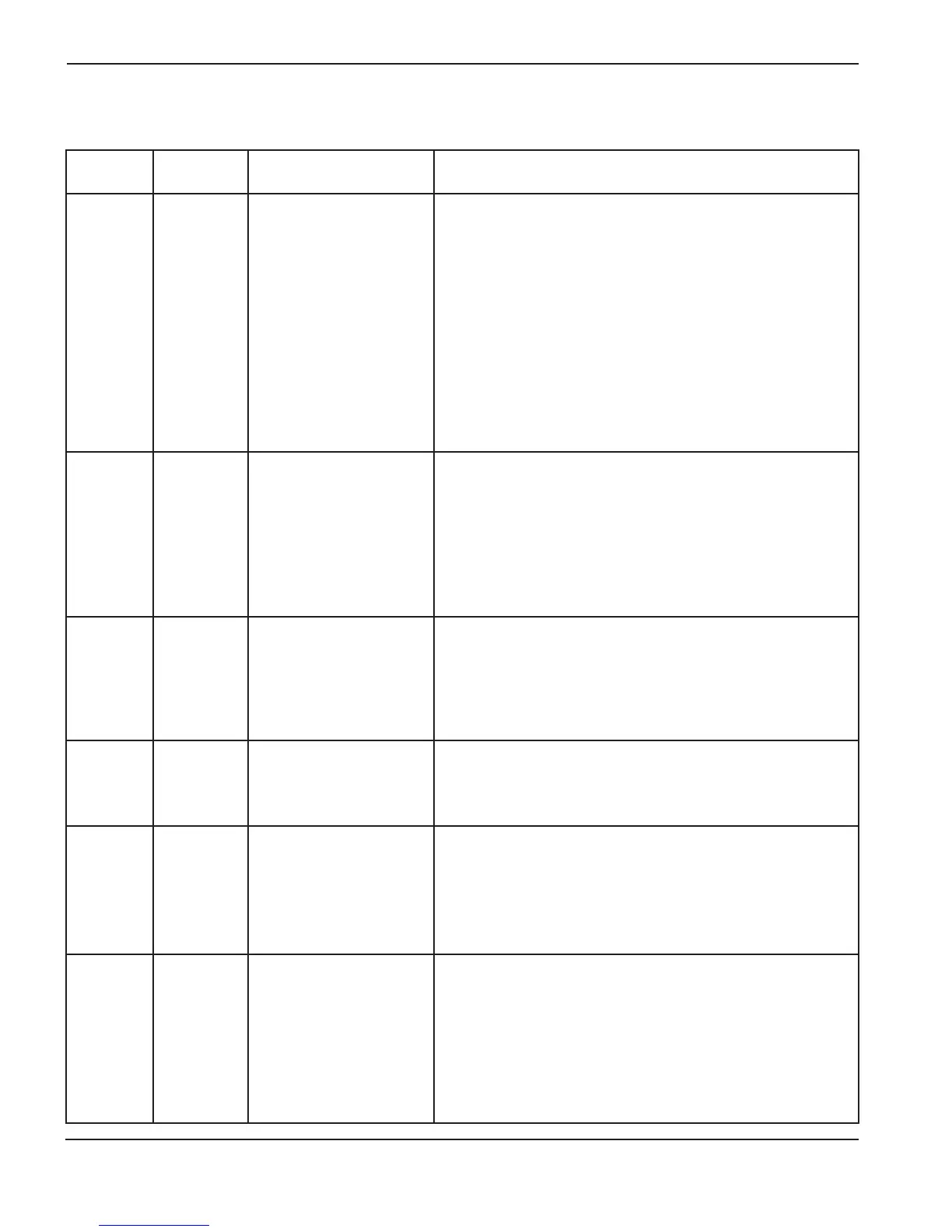

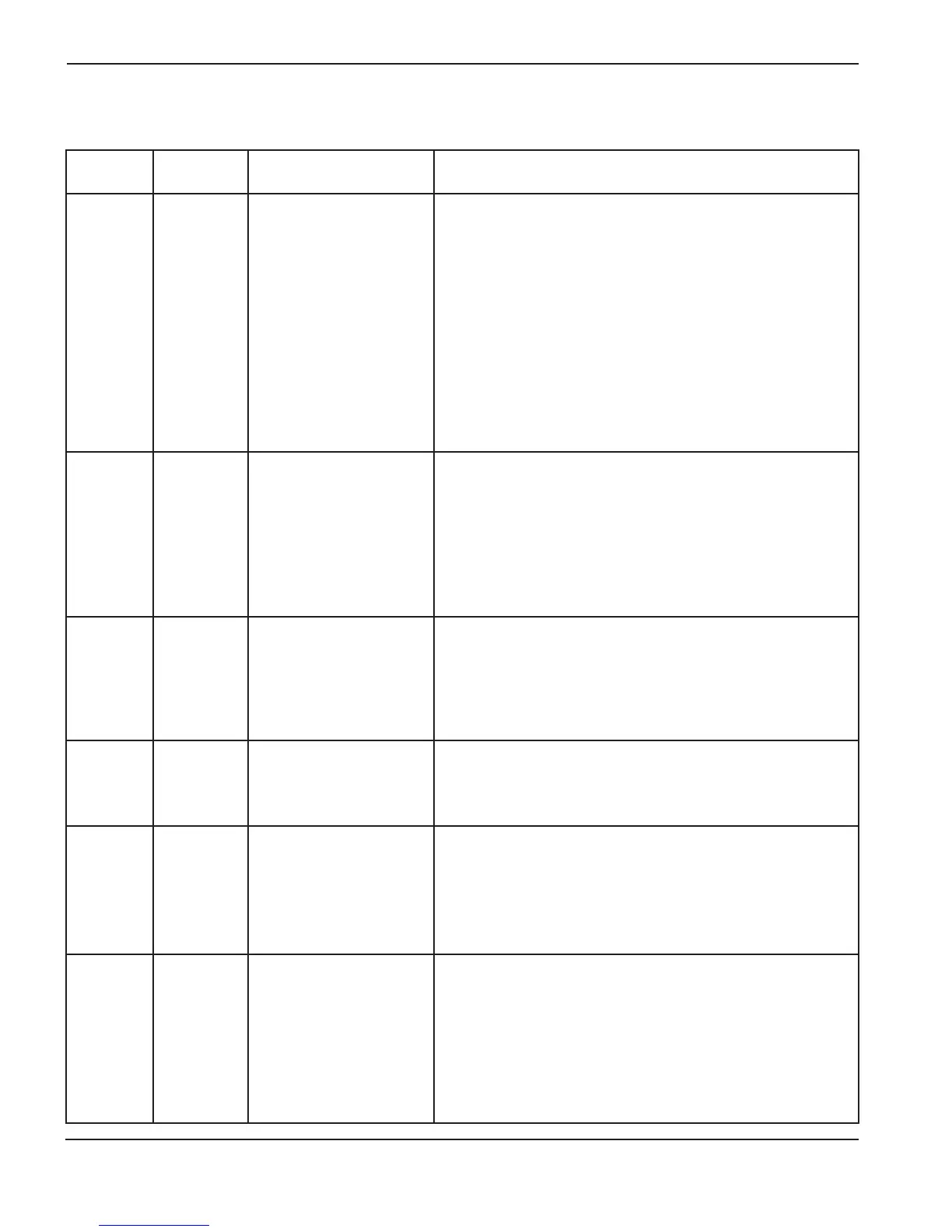

Error code troubleshooting – 3 of 16

Error code

number

Name Description Corrective action

030

Gas system

error

Auto Gas

Only

A failure has occurred in

the gas system.

1. Verify that cable number 5 (power supply-to-gas console

control cable) is not damaged and is properly connected to

PCB3 and to the rear of the gas console.

2. Verify that cable number 6 (power supply-to-gas console

power cable) is not damaged and is properly connected

inside the power supply and to the rear of the gas console.

3. Verify that D1 (+5 VDC) and D2 (+3.3 VDC) are illuminated

on PCB2 inside the gas console. These LEDs indicate

power to PCB2.

4. If power is present at PCB2 and PCB3 and both gas

console cables are good, then PCB2 or PCB3 has failed.

Use the CAN tester to verify which board needs to be

replaced.

031 Start lost

Start signal was received

and then lost before an arc

was established.

1. If a mechanical relay is being used to provide the HPR with

a start signal, this relay is either bouncing when activated or

the contacts are faulty. Replace the relay.

2. Inspect interface cable for damage; faulty crimps, or poor

electrical connections.

3. If interface cable is good and a relay is not driving the start

input, the CNC is dropping the start signal before a steady

state arc has been established.

032 Hold timeout

Hold signal was active for

longer than 60 seconds.

1. Check the interface cable for damage. The hold wires may

be short-circuiting inside.

2. The CNC is maintaining this input, it could be waiting for an

IHS complete input from another torch.

3. If CNC interface cable is good and it is a 1-torch system,

change PCB3.

033

Precharge

time-out

Auto Gas

Only

Selection console was not

able to charge the lines to

the correct value.

This is a warning for a possible gas restriction in the leads.

Verify that there are no restrictions in the plasma and shield

hoses, or low inlet-gas pressure.

034

Lost current

Chopper 4

Lost the current signal

from Chopper 4 after

transfer.

1. Verify that the consumable parts are in good condition.

2. Verify proper cut-flow gas settings.

3. Verify pierce delay time.

4. Verify arc did not lose contact with plate while cutting (hole

cutting, scrap cutting, etc).

5. Perform chopper test (see Maintenance section).

042

Low nitrogen

(N2) gas

pressure

Nitrogen gas pressure

under lower limit of

2.07 bar (30 psi) – cutting

0.34 bar (5 psi) – marking

During N2 purge, when

changing between a fuel

gas process and an

oxidizer process.

1.Verify that the nitrogen supply is turned on and inspect gas

supply pressure and volume of gas remaining in supply tanks.

2. Verify that the gas regulator is set to 8.27 bar (120 psi). See

Setting the supply regulators (Installation section).

5-12 HPR400XD Manual Gas Instruction Manual

MAINTENANCE

Loading...

Loading...