106 HyPrecision Predictive waterjet pump Operator Manual 810120

5 – Preventive maintenance

Preventive maintenance

1. Tape a sheet of lapping paper on a granite lapping block. Make sure that the paper is smooth and flat.

2. Put the check valve or poppet face flat on the lapping paper and move it back and forth. Apply light pressure.

3. After each stroke, turn the flat face of the part 45°.

4. Do this procedure again until the face is smooth and flat and has an almost mirrored finish.

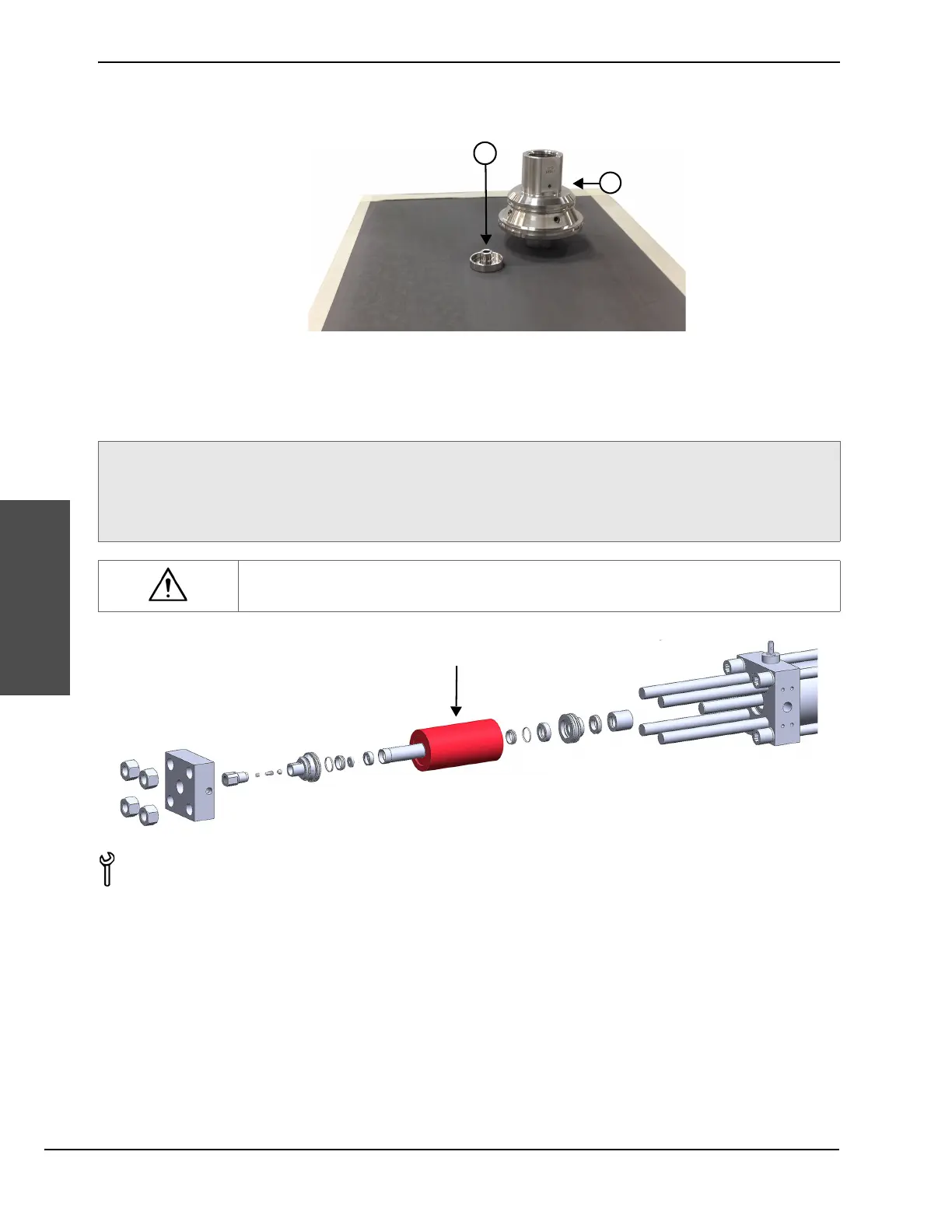

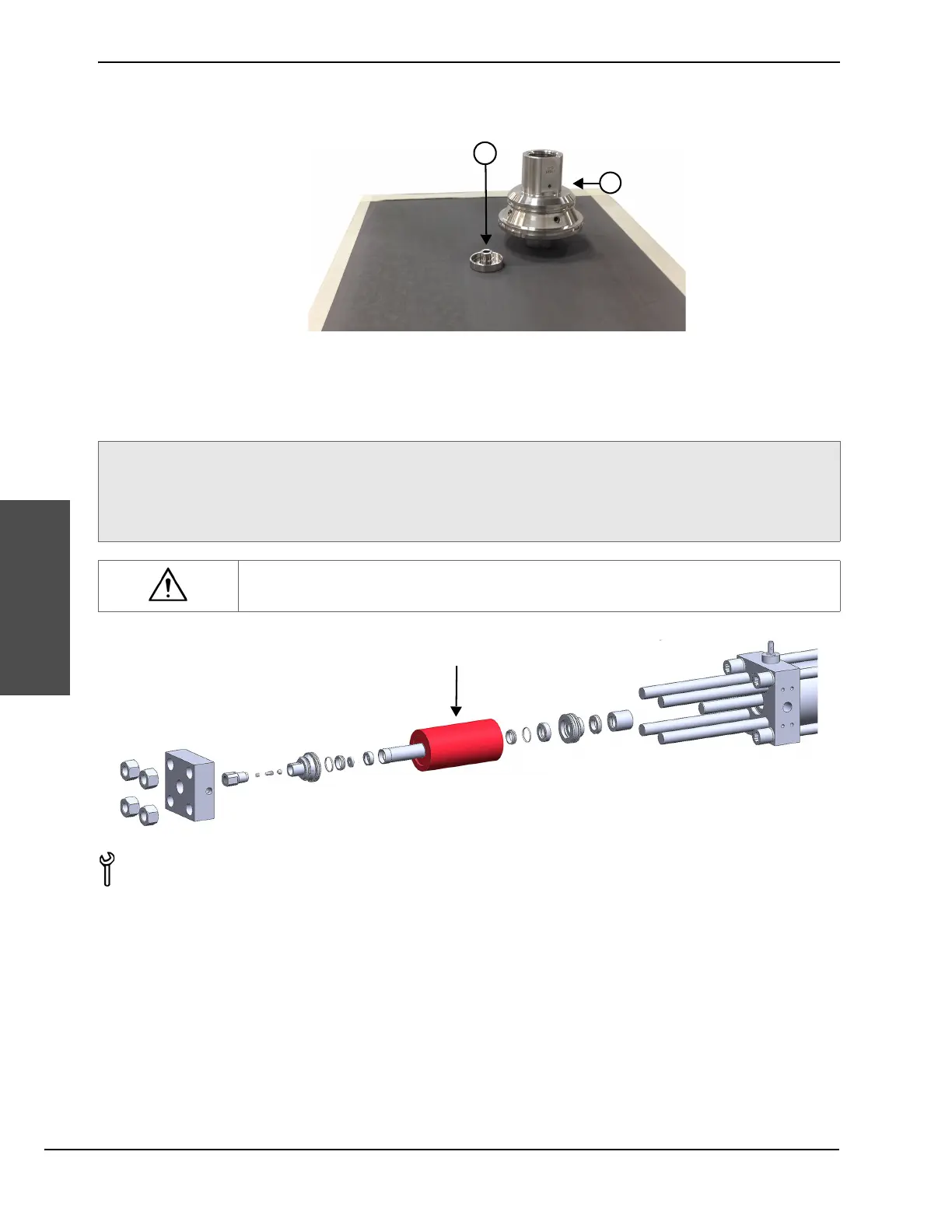

Repair the high-pressure cylinders

Parts, tools, and materials

Repair the high-pressure cylinders every 500 hours.

Replace the high-pressure cylinders:

• every 3,000 hours

• if the cylinder is chipped or cracked

Debris in the cylinder can cause the seals or the poppets to fail.

1-11210-12 Lapping paper, 12 micron

Clean towels

Nonstick scouring pad

Isopropyl alcohol

Emery cloth (no coarser than 120 grit)

Loading...

Loading...