HyPrecision Predictive waterjet pump Operator Manual 810120 197

9 – Installation

Installation

Requirements

Location

Put the equipment on a flat surface, such as concrete, that can hold the weight of the equipment and is thick

enough to resist vibration. The feet on the frame can be adjusted to level the pump with two 1-1/8-inch

open-ended wrenches.

Make sure that there is sufficient space for auxiliary equipment such as a water softener, a reverse osmosis

system, or a chiller.

Temperature

For temperature specifications, refer to Environmental conditions on page 178.

Ambient temperature can have an effect on cooling. Supplementary cooling can be necessary for a pump that is

installed in a small or high-temperature location.

Cooling

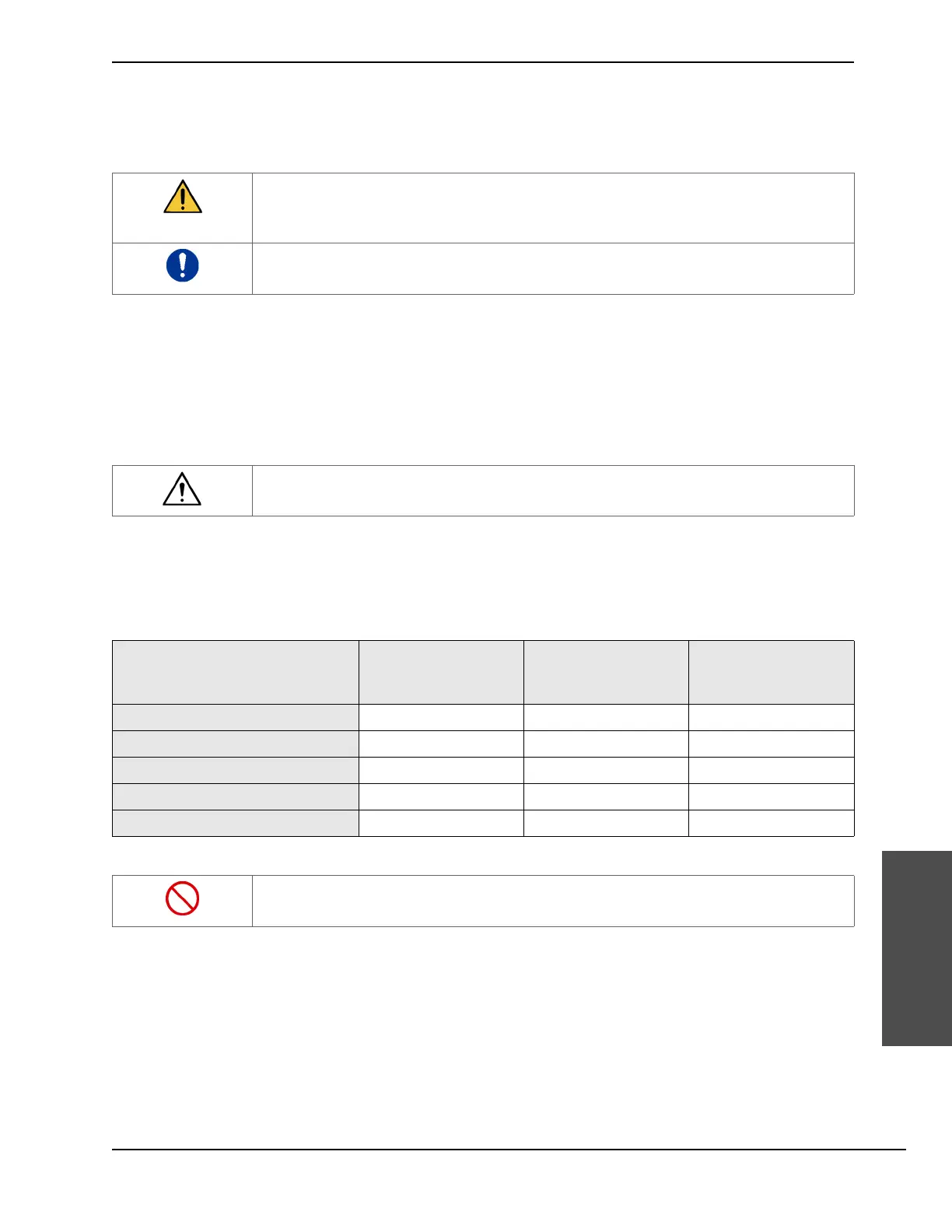

Chiller

Using a chiller with a water-glycol solution can have an effect on the performance of the heat exchanger.

Hydraulic fluid

For hydraulic fluid specifications, refer to Hydraulic fluid on page 178.

Hypertherm does not always ship the pump with hydraulic fluid in the tank.

WARNING

Some locations can be dangerous if the atmosphere contains gas, vapors, or dust in explosive

quantities. Refer to requirements from the National Electric Code (NEC), the International

Electrotechnical Commission (IEC), the Occupational Safety and Health Administration (OSHA),

and other national and local codes for information about environmental criteria.

Make sure that there is a minimum clearance of 91 cm (36 inches) on all sides of the equipment to

permit air movement for cooling and space for maintenance and repairs.

Do not install this equipment in an area where the temperature is below freezing. Freezing can

cause damage to low-pressure and high-pressure water parts.

HyPrecision pump model

kW

(minimum)

Refrigeration tons

(minimum tons)

Heat removal

requirement

(minimum Btu/hour)

P-15 3 0.85 10,000

P-30 6 1.70 20,000

P-50 and P-50S 9 2.70 32,000

P-60S 11.5 3.30 40,000

P-75S 14 4.00 48,000

Do not use a glycol solution in a chiller at a concentration higher than 25%.

Loading...

Loading...