5-12 MAX200 Instruction Manual

MAINTENANCE

Adjusting Plasma Gas

If you have increased torch lead length from 50 feet or under to 75 feet or over, the plasma gas pressure must be

re-adjusted to accommodate the extra torch lead length:

1. At the front panel of the MAX200 power supply while in TEST mode, adjust the PLASMA gas valve control by

increasing the TEST pressure approximately 5 psi per 50 ft of lead length (beyond 50 ft) from what is called

out in the Cut Charts. See note on page 4-17.

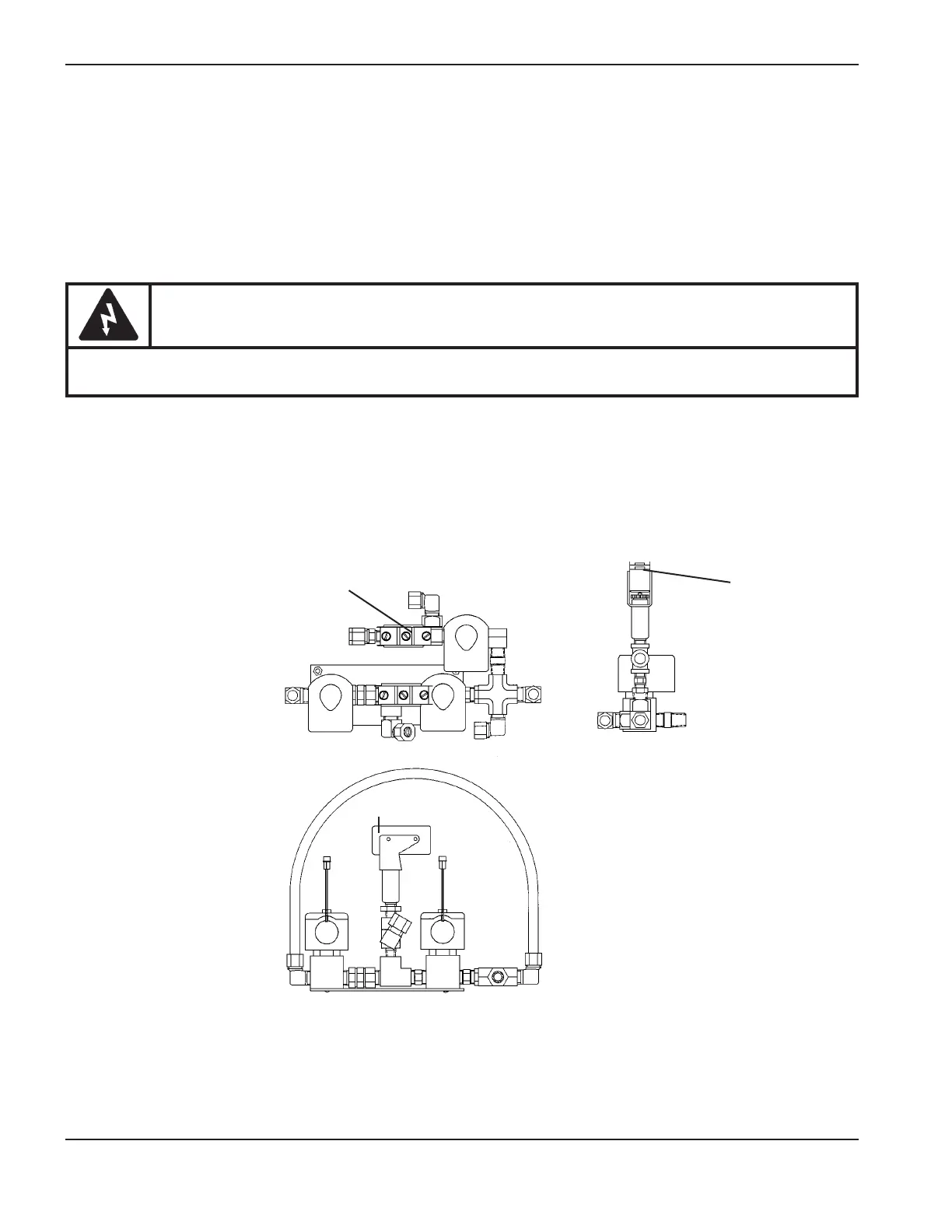

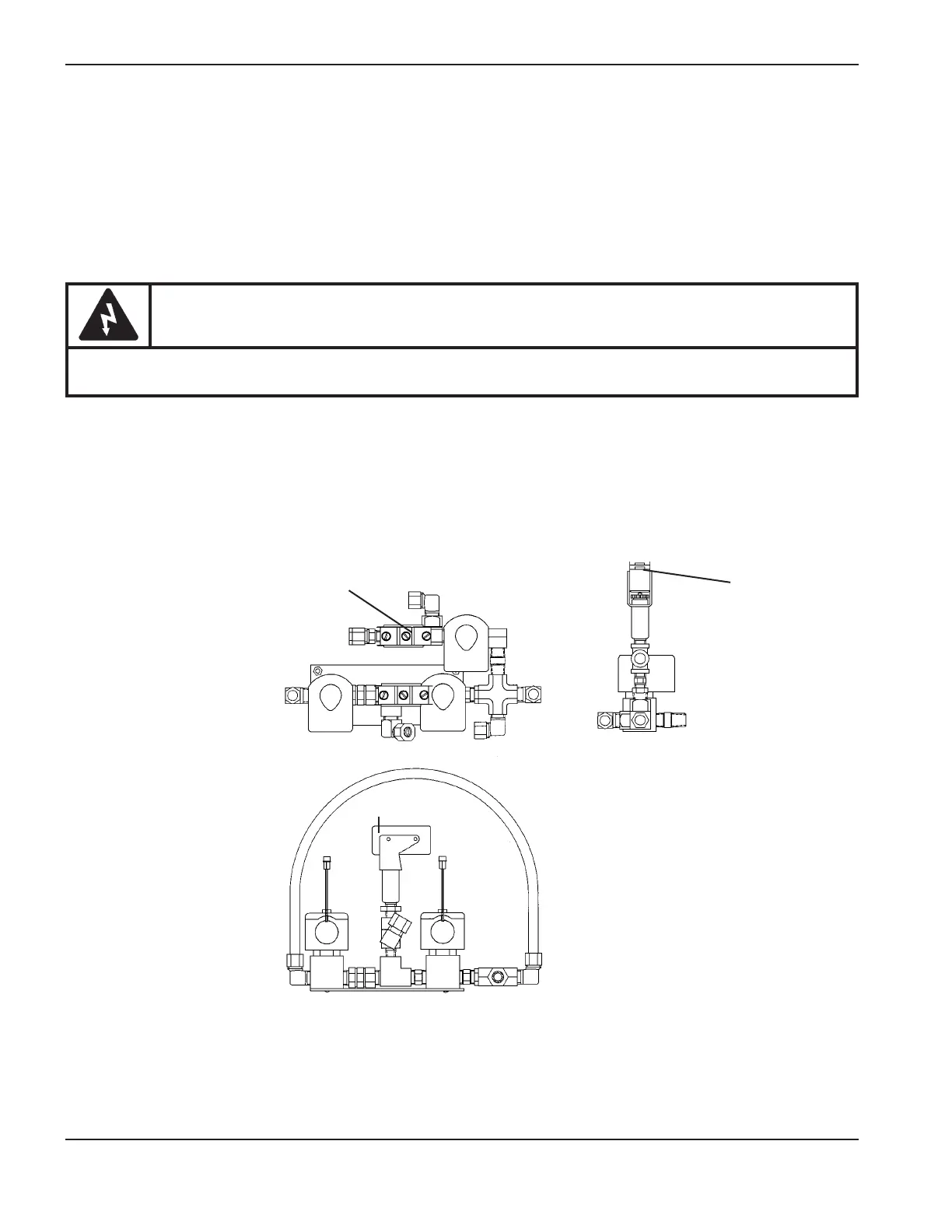

Figure 5-4 Pressure Switch PS4 and Adjustment Location

RIGHT SIDE VIEW

PS4 (on inside)

PS4

PS4

Adjustment

TOP VIEW

2. If the plasma gas RUN pressure does not quickly reach the value stated in the Cut Charts after arc transfer,

you may need to adjust PS4. Remove the right side panel of the power supply. On the floor of the power supply,

locate pressure switch PS4 by referring to Figure 5-4 and adjust by turning the PS4 Adjustment screw in a

clockwise direction.

WARNING

Use extreme caution when making the following adjustment:

Loading...

Loading...