End users will need to be instructed on how to maintain the filter in the boiler.

For instructions on how to replace the filter, see Replacing the air filter on

page 76.

Figure 22 Filter door - top view of boiler

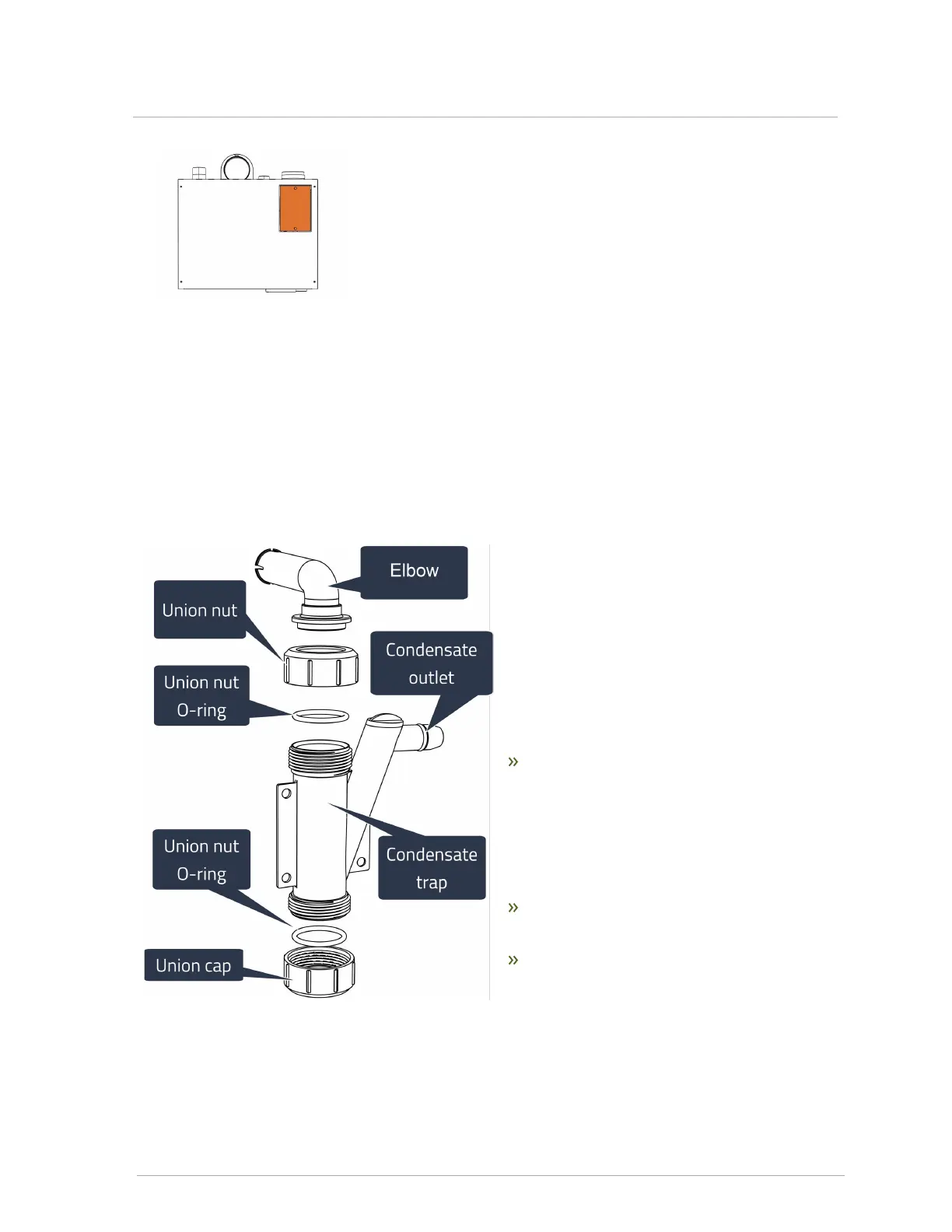

3.6 Installing a condensate trap

IBC’s specified vent configuration promotes the safe drainage of moisture from the boiler and exhaust

venting without flowing liquids back through the heat exchanger (as done by some other condensing

boilers).

Reliable system operation requires:

1. Proper design and installation of exhaust

venting to allow condensate to run back to the

drain/trap.

2. Acid neutralization as appropriate.

To achieve these:

Allow a minimum ¼" per foot slope back to the

vent connection, with appropriate hangers to

maintain that gradient. For PPs venting, follow

the manufacturer's requirements. This will

ensure proper drainage and prevent

condensate from clogging.

Ensure the supplied trap is correctly installed

and filled with water.

When required, add (and maintain in good

condition) a neutralization tank. For information

on installing a condensate neutralizer, see

Installing a condensate neutralizer on page 39.

3.6 Installing a condensate trap

Loading...

Loading...