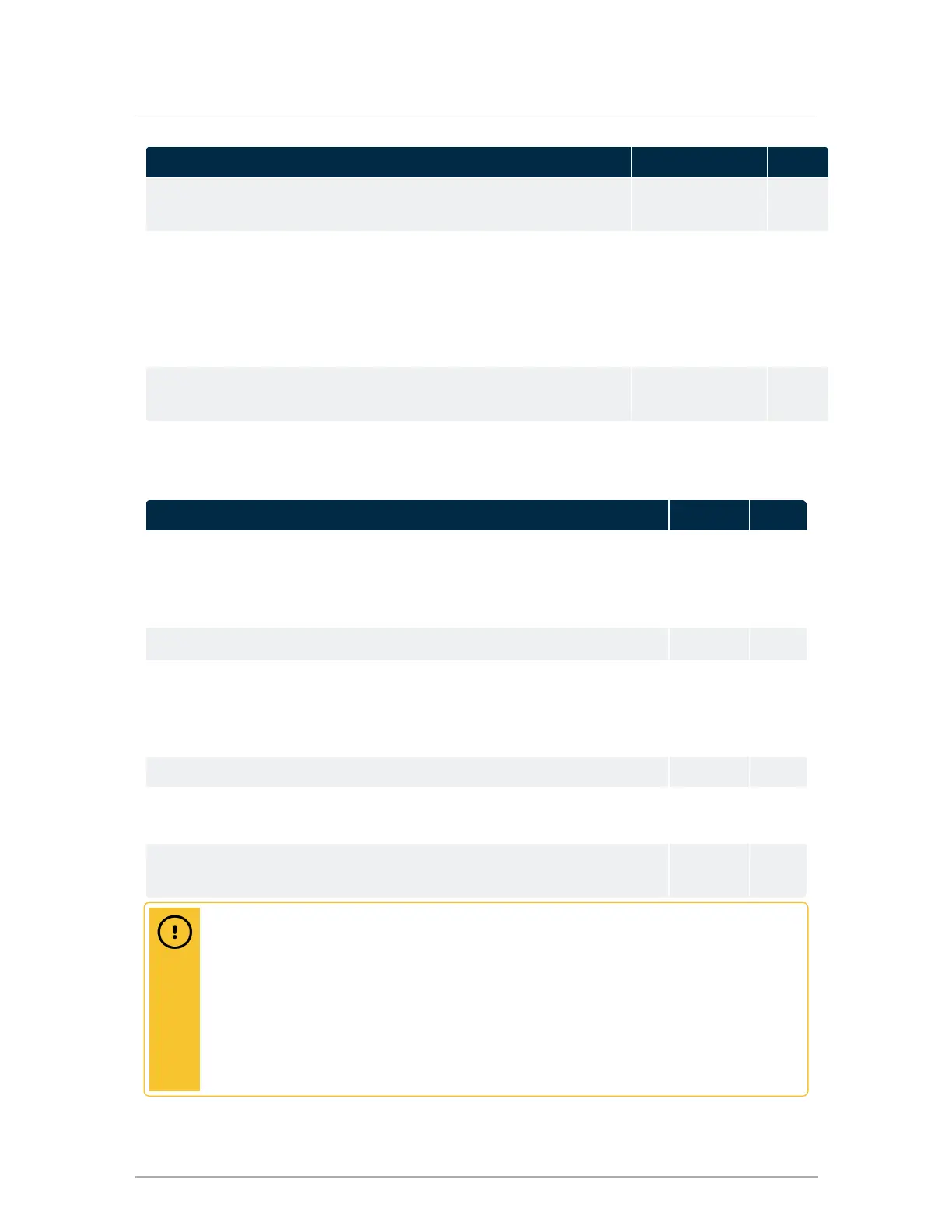

Maintenance Required for Boiler Controller Frequency Check

Check that water temperature targets and setpoint is satisfactory and have

not been adversely amended.

Annually

□

Check the operating history using the boilers Logs menu and Error Logs

menu.

The controller tracks the duty cycle of the boiler in each of the 4 loads

separately. This information can be used to adjust the water temperatures

of each load.

□

If a problem exists with the controller, consult the section Troubleshooting

on page 79.

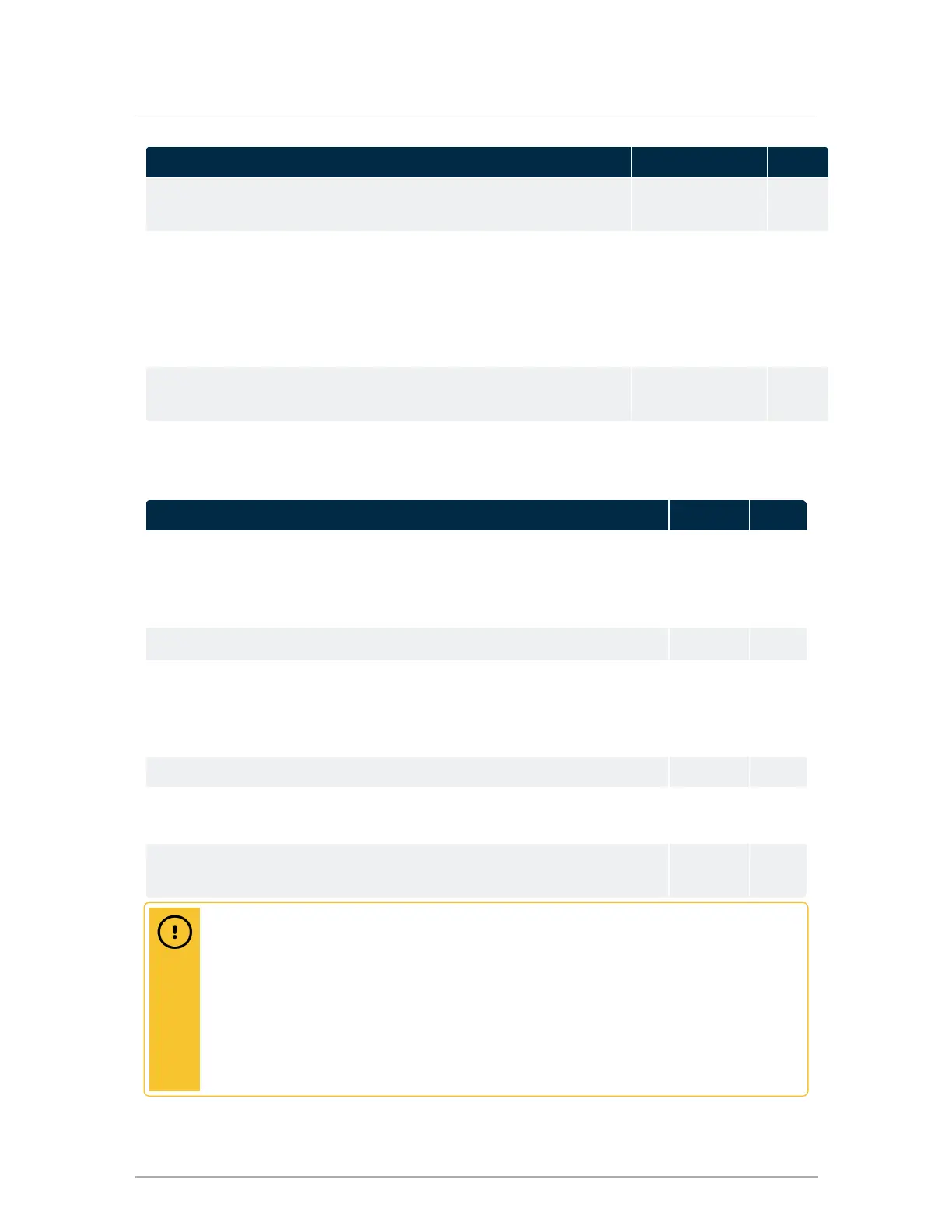

6.2.8 Water

Checks for Water in the Boiler Frequency Check

Check water pressure and temperature.

There should be no noticeable change if boiler is functioning normally. Check for

any noise in the system.

Annually

□

Check water piping for damage or leaks and repair as needed.

Annually

□

Check the water pressure. Pressure should be stable when the boiler is firing and

the water temperature is rising.

If pressure rises sharply, consider replacement of expansion tank.

Annually

□

Check also for noise at high fire, which may signal water quality problems. Annually

□

Water chemistry shall be of a quality generally accepted as suitable for hydronic

applications.

Annually

□

Ensure any direct “city fill” water connections are left in the closed position to

minimize exposure to leaks and flooding.

Annually

□

Caution

Installers should inquire of local water purveyors as to the suitability of their supply for use in

hydronic heating systems.

If water quality is questionable, a local water treatment expert must be consulted for testing,

assessment and, if required, treatment.

Alternatively, water or hydronic fluid of known quality can be brought to the site.

Section: Service and maintenance

Loading...

Loading...