21

CHAPTER 4

CHAPTER 4 - BOILER PIPING

To ensure an adequate flow rate through the EXALT

Solo, the boiler supply and return piping size must be a

minimum of 1 inch for the EXALT Solo 110, 1-1/4 inch for

the EXALT Solo 155/199.

4.7.11 System Piping – Special Application

If the boiler is used in conjunction with a chilled water/

medium system, the boiler and chiller must be piped in

parallel. Install ow/check valves to prevent the chilled

medium from entering the boiler.

If the boiler is used to supply hot water to the heating

coils of an air handler where they may be exposed to

chilled air circulation, install ow/check valves or other

automatic devices to prevent gravity circulation of the

boiler water during cooling cycles.

4.7.12 System Piping – Multiple Units Installation

Use a balanced manifold system as the primary /

secondary connection to the space heating piping.

For the space heating piping, refer to the applications

mentioned in this manual or use recognized design

methods.

NOTICE

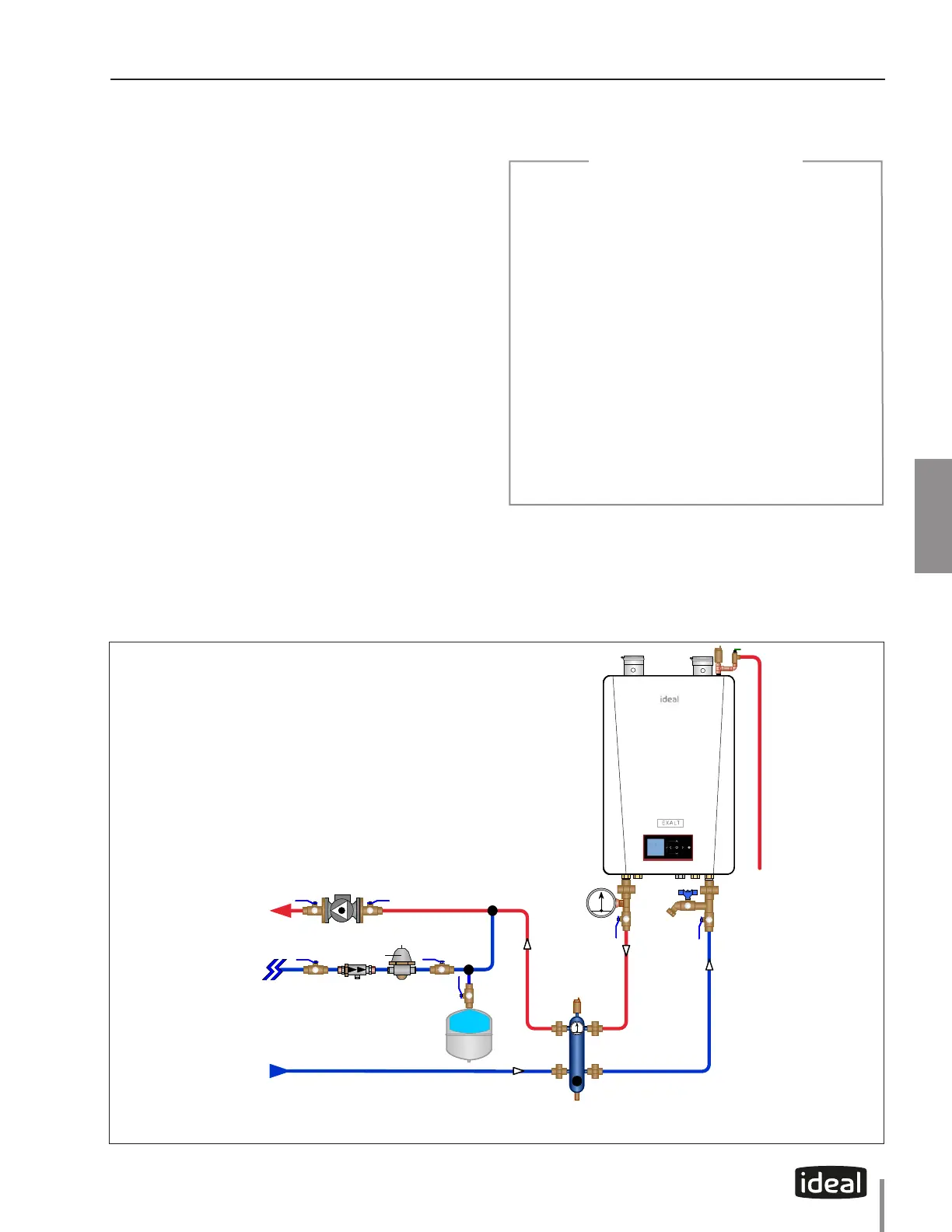

4.8. EXALT Combi Boiler System Piping

It is recommended on all piping applications to

utilize a primary/secondary piping arrangement as

a means to provide freeze protection of the boiler,

which is an integral function of the boiler control.

Maintain at least the minimum boiler flow rate

shown in the Graphs of Chapter 19 on page 101. For

other piping arrangements, contact Ideal Technical

Support or consult other approved/recognized

design arrangements.

On piping applications utilizing a single zone or

other recognized piping design arrangements, it

is recommended that the installer uses flow/check

valves with weighted seats at or near the EXALT

Combi to prevent gravity circulation.

BEST PRACTICEBEST PRACTICE

Fig. 11 - EXALT Combi Near Boiler Piping - Hydraulic Separator

Cold

Water

Fill

T PT P

System

Supply

System

Return

Loading...

Loading...