22

CHAPTER 4

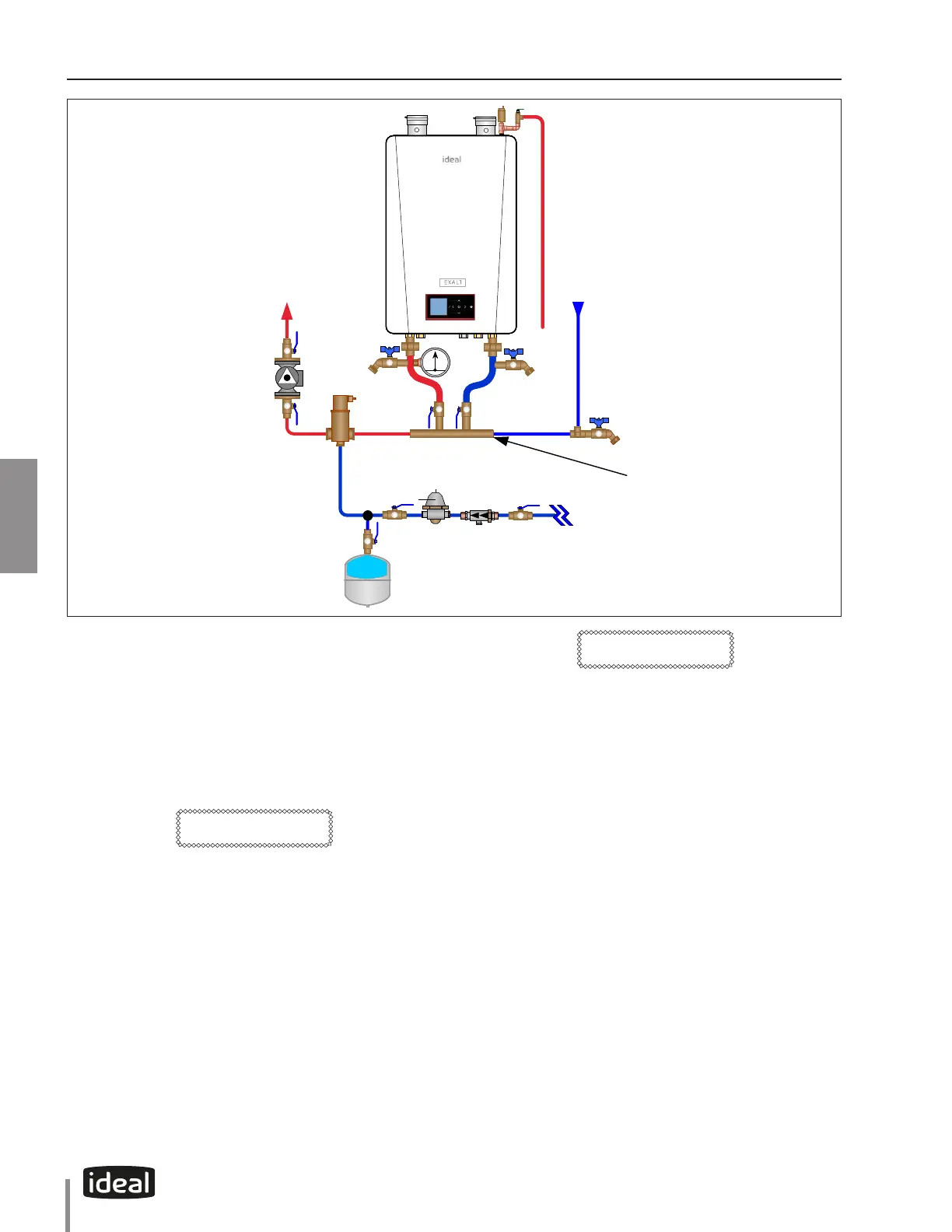

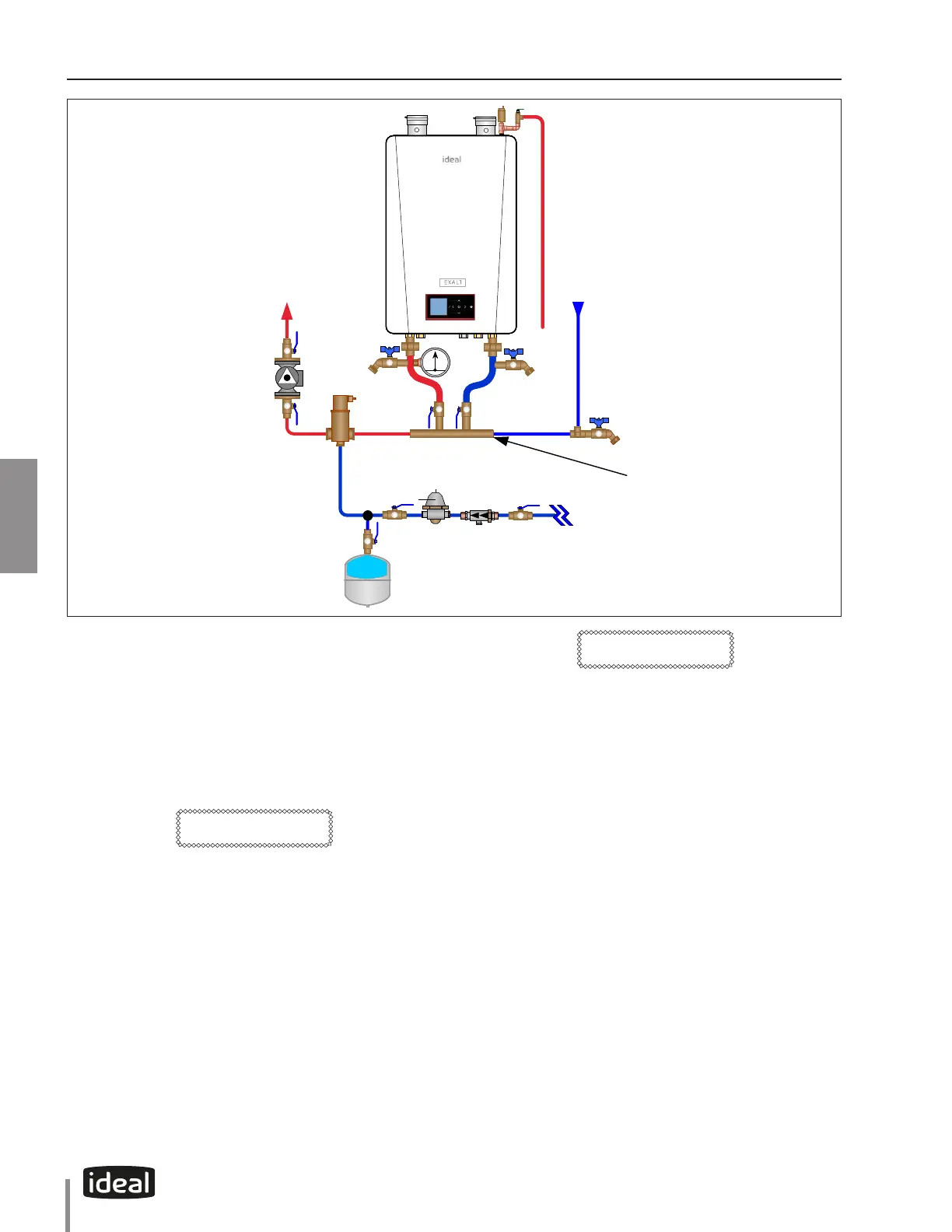

The expansion tank must be located directly on the

EXALT Combi return pipe, before the return check

valve. Incorrect expansion tank location will cause

system water to be lost through the pressure relief

valve and cause additional makeup water to be added

to the system. Eventual boiler heat exchanger failure

can result due to this excessive makeup water addition.

4.8.2 Diaphragm Expansion Tank

Always install an automatic air vent on top of the air

separator to remove residual air from the system.

4.8.3 Circulator

The EXALT Combi is supplied with a Boiler circulator

that provides circulation for central/space heating (CH)

and Domestic Hot Water (DHW) production. See Graph

2 on page 112.

CAUTION

CHAPTER 4 - BOILER PIPING

4.8.1 Expansion Tank and Makeup Water

Ensure the expansion tank is properly sized for the

boiler volume:

• 3 gallons [12 L] for the EXALT Combi 155

• 4 gallons [15 L] for the EXALT Combi 199

the system water volume, and the system water

temperature.

Undersized expansion tanks will cause system water

to be lost through the pressure relief valve and

cause additional makeup water to be added to the

system. Eventual boiler heat exchanger failure can

result due to this excessive makeup water addition.

The expansion tank must be located as shown in

Fig. 11 on page 21 when using a primary/secondary

piping arrangement. Refer to the expansion tank

manufacturer for additional installation details.

Connect the expansion tank to an air separator only if

the air separator is located on the suction side (inlet)

of the system circulator. Always locate and install the

system ll connection at the same location as the

expansion tank connection to the system.

CAUTION

System

Supply

Cold

Water

Fill

System

Return

T PT PT P

Optional Instinct

Combi Timesaver

EXRKIT84

Fig. 12 - EXALT Combi Near Boiler Piping - Timesaver Manifold

Optional Exalt

Combi Timesaver

EXRKIT84

Loading...

Loading...