25

Installation and Servicing

Section 2 - Installation

INSTALLATION

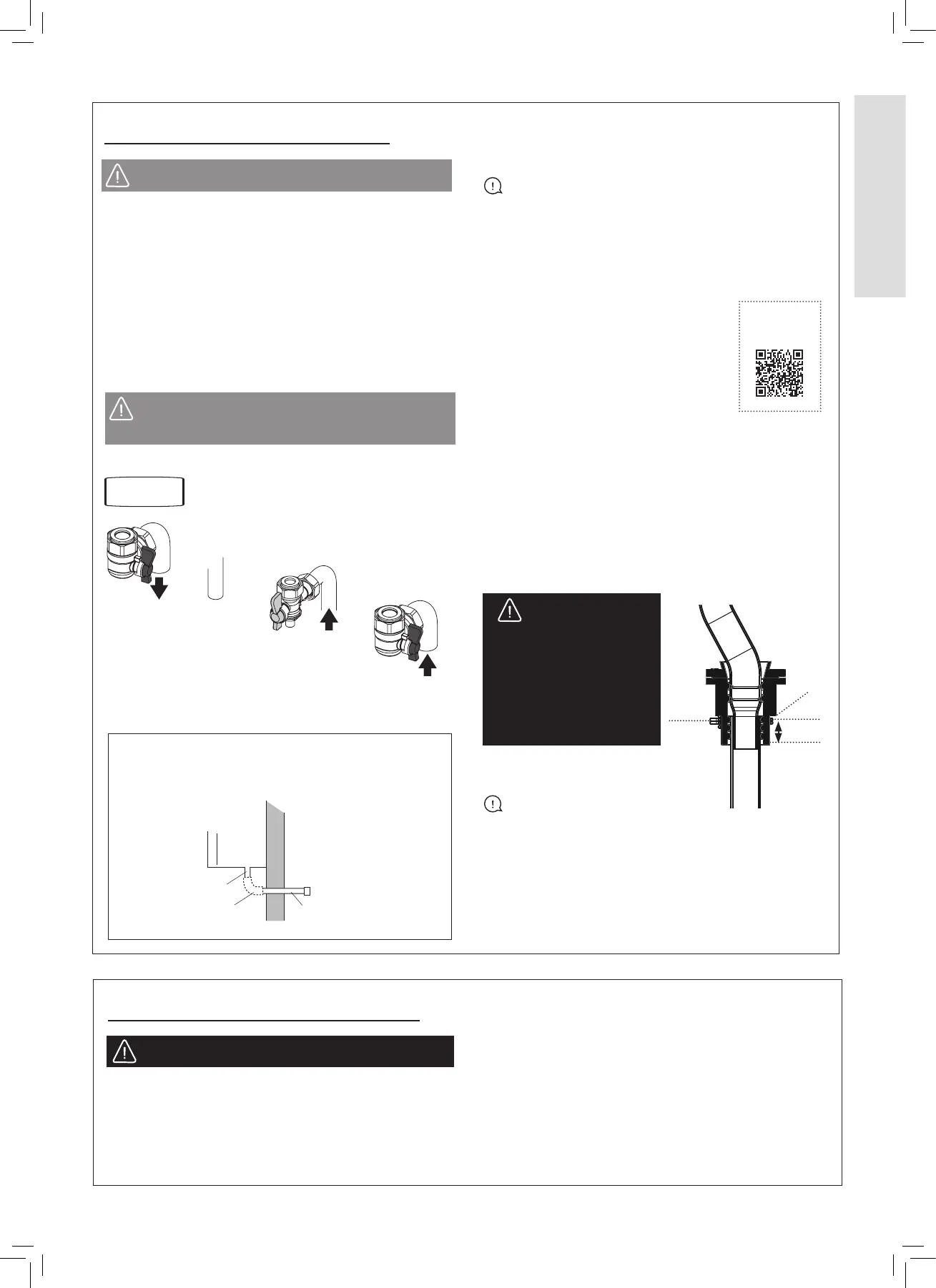

PRV

Drain Connection

15 mm Fitting

(not supplied)

PRV

Drain Pipe (supplied)

A purpose made PRV drain pipe is provided with the boiler

to allow safe discharge through a wall to the outside of the

building. This is particularly relevant to ‘high rise’ installations

but can be used for all installations.

PRV DRAIN

The PRV connection, located at the bottom left-hand side of

the boiler, comprises an open ended grommet.

IMPORTANT

The grommet is designed for 15 mm Ø copper pipe.

If possible, preassemble and solder the pipework before

Installing.

If this is not possible the soldering must be more than

100 mm away from the grommet. Make sure the grommet

is not damaged by the heat.

Install the condensate pipe as follows:

1. Make sure that the 15 mm Ø copper

pipe is cut perpendicular to the pipe.

2. Make sure that the pipe is not

damaged, and clean and free from burs.

3. Using pliers put the clip over the

grommet. Continue to hold the clip open.

Note. Do not release the clip until step 5 (see below).

4. Push the copper pipe into the grommet (minimum of

15 mm). Make sure that the pipe is parallel with the

grommet.

5. Below the stop mark on the grommet open the pliers to

release the clip.

6. Make sure that the clip and pipe are attached correctly.

7. Make sure that the PRV discharge pipe is correctly

attached. Make sure that the angle of the pipe run is

sucient to remove discharged water.

.

FILLING

IMPORTANT - when lling:

A. Ensure the dust cap on air vent located at the rear of the

pump chamber is slightly unscrewed.

B. When lling, there may be a slight water leak from

the air vent therefore electrical connections should be

protected.

1. Ensure that the CH isolating handles are open.

2. Fill and vent the system. Check for water soundness.

Isolation handles are shown in the open position.

Yellow

Handle

Black

Handle

Black

Handle

CH Flow

Gas

Supply

CH Return

PRV

Outlet

Remove all boss blanking plugs before connecting the

hardware.

Fit each union with the bre seals provided.

WATER CONNECTIONS CH

1. Connect the CH ow service valve (black handle) and

copper tail provided in the hardware pack to the threaded

boss connection provided at the lower rear of the boiler.

2.

Connect the CH return. valve (black handle) and copper tail.

GAS CONNECTION

For details of the position of the gas connection:

Refer to Gas Supply

1.9

CAUTION: The gas service cock is sealed with a

non-metallic blue bre washer, which must not be

overheated when making capillary connections.

Stop

point

Clip

15 mm

SCAN

for video

WARNING:Make

sure that the water or

steam (from the boiler)

is discharged safely.

Hot water or steam is

dangerous and can cause

serious injury, and damage

to electrical systems.

2.17 CONNECTIONS & FILLING

CAUTION: Heating the isolation valves may damage

the bre seals

2.18 ELECTRICAL CONNECTIONS

Wiring should be 3 core PVC insulated cable, not less than

0.75 mm

2

(24 x 0.2 mm), and to BS 6500 Table 16.

Connection must be made in a way that allows complete

isolation of the electrical supply. The means of isolation

must be accessible to the user after installation.

A mains supply of 230 V ~ 50 Hz is required.

3 A fuse required. All external controls and wiring must be

suitable for mains voltage.

Wiring external to the boiler must follow current I.E.E

(BS7671) wiring regulations and local regulations.

WARNING: This appliance must be earthed

Loading...

Loading...