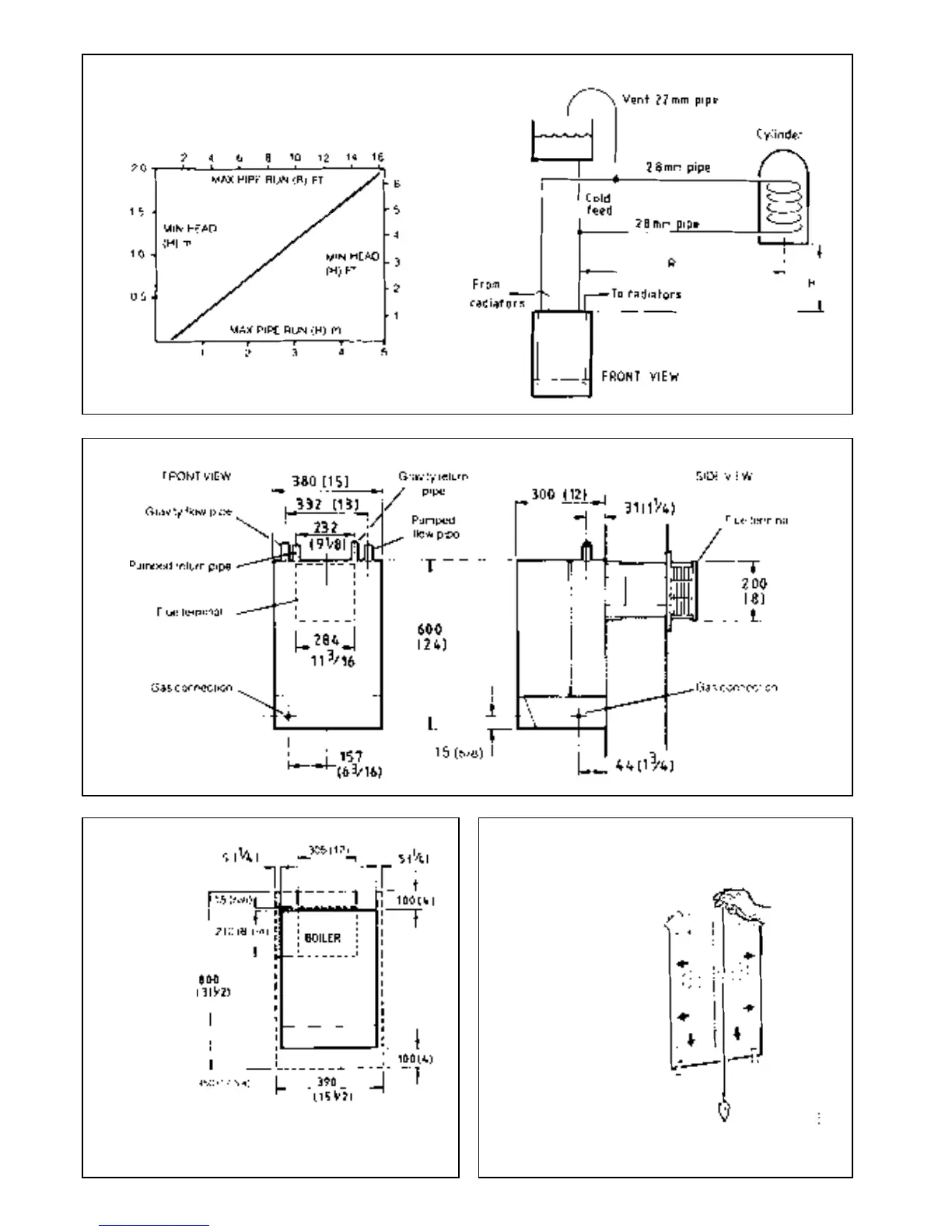

SYSTEM DESIGN - BOILER DIMENSIONS & CLEARANCES

INSTALLATION

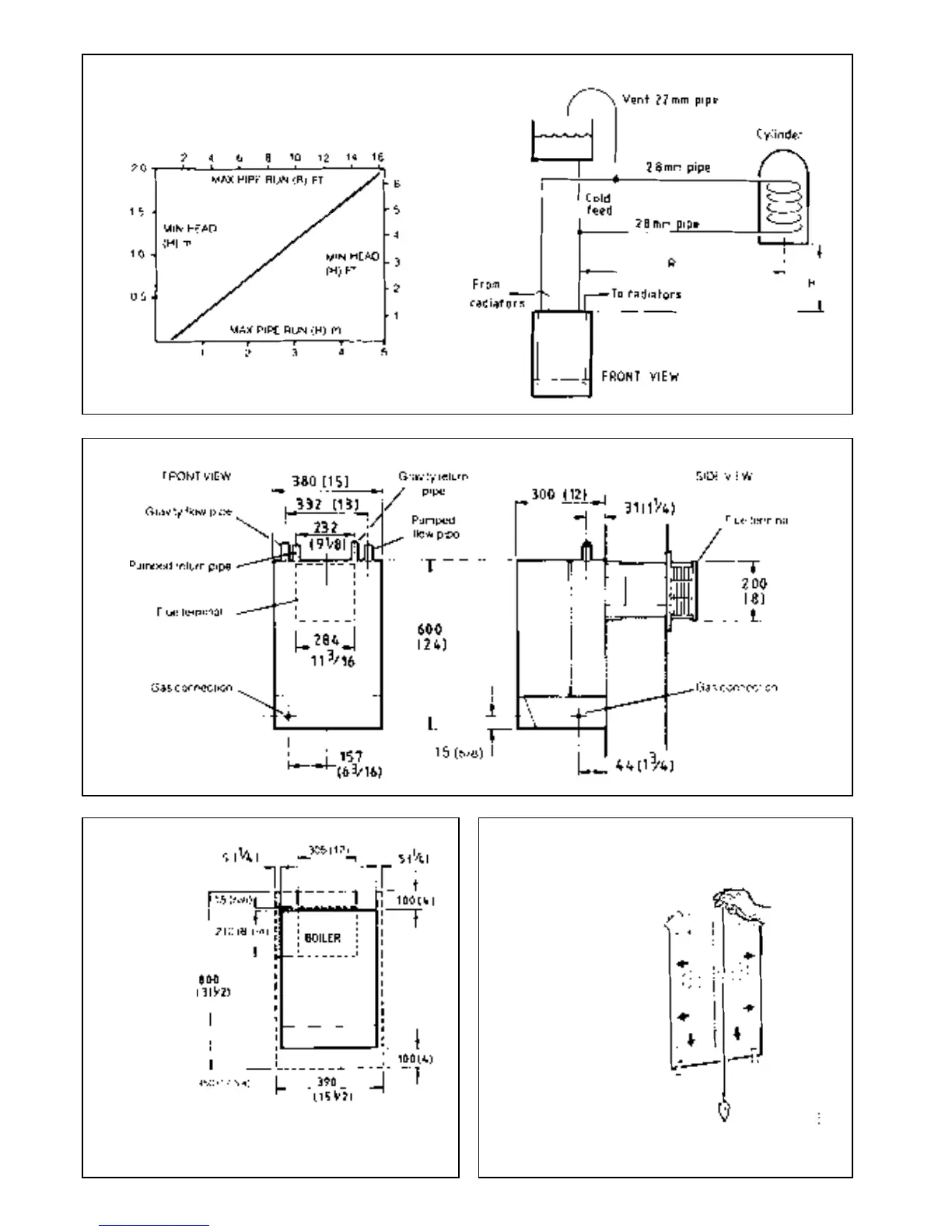

5 REQUIREMENTS FOR CORRECT GRAVITY HOT WATER PERFORMANCE

7 CLEARANCES & TERMINAL OPENING

1. Tape the template to the wall in the selected position.

Ensure squareness by use of a plumbline - as shown.

2. Mark out the position

of the 3 wallplate

screws, choosing 1

from each group of 3

holes. Also mark the

position of the hole

for the duct, the

jacking plate screw

and the top cover

plate screws.

3. Drill the three holes,

8 mm (5/16 in.), and

insert the 3 plastic

plugs. Also drill the

jacking plate screw

and the top cover

plate screw holes and

insert the plastic

plugs.

8

6 BOILER DIMENSIONS / SERVICES

All dimensions in mm (in.)

4. Remove the template from the wall.

8 WALL MOUNTING TEMPLATE

NOTE: Gravity horizontal pipes should be ABOVE ceiling level and

as SHORT as possible. A MINIMUM inclination of 25 mm per 3 m

run (1 in per 10 ft.) is required to avoid air locks. If these conditions

cannot be met, pumped primaries MUST be used.

The above graph assumes 8 elbows in the gravity circuit. For each

elbow in excess of 8, (R) must be reduced by 300 mm (12 in.) or

(H) increased by 100 mm (4 in.)

1

Front clearance

from the front of

the boiler casing.

These are the

minimum

clearances

needed to allow

access to service the boiler, but additional space may be needed

for installation, depending on site conditions. Note: If using the

sealed system module, refer to the instructions packed with the

module for the necessary clearances.

Loading...

Loading...