The boiler is fitted with a special drain plug which is provided

to drain the BOILER ONLY in the event of the system drain

plug being unable to do so.

The hydraulic resistance of the boilers, at MAXIMUM OUTPUT

with an 11 °C (20°F) temperature differential, are shown in

Table 8.

THERMOSTATIC RADIATOR VALVES

Caradon Ideal Ltd. recommend that heating systems utilising

full thermostatic radiator valve control of temperature in

individual rooms should also be fitted with a room thermostat

controlling the temperature, in a space served by radiators not

fitted with such a valve - as stated in BS 5449.

When thermostatic radiator valves are used, the space heating

temperature control over living / dining area or hallway, having

a heating requirement of at least 10% of the boiler heat output,

should be achieved using a room thermostat whilst other

rooms are individually controlled by thermostatic radiator

valves. However, if the system employs thermostatic radiator

valves on all radiators then a bypass must be fitted to ensure a

flow of water should all the TRV's be in the closed position.

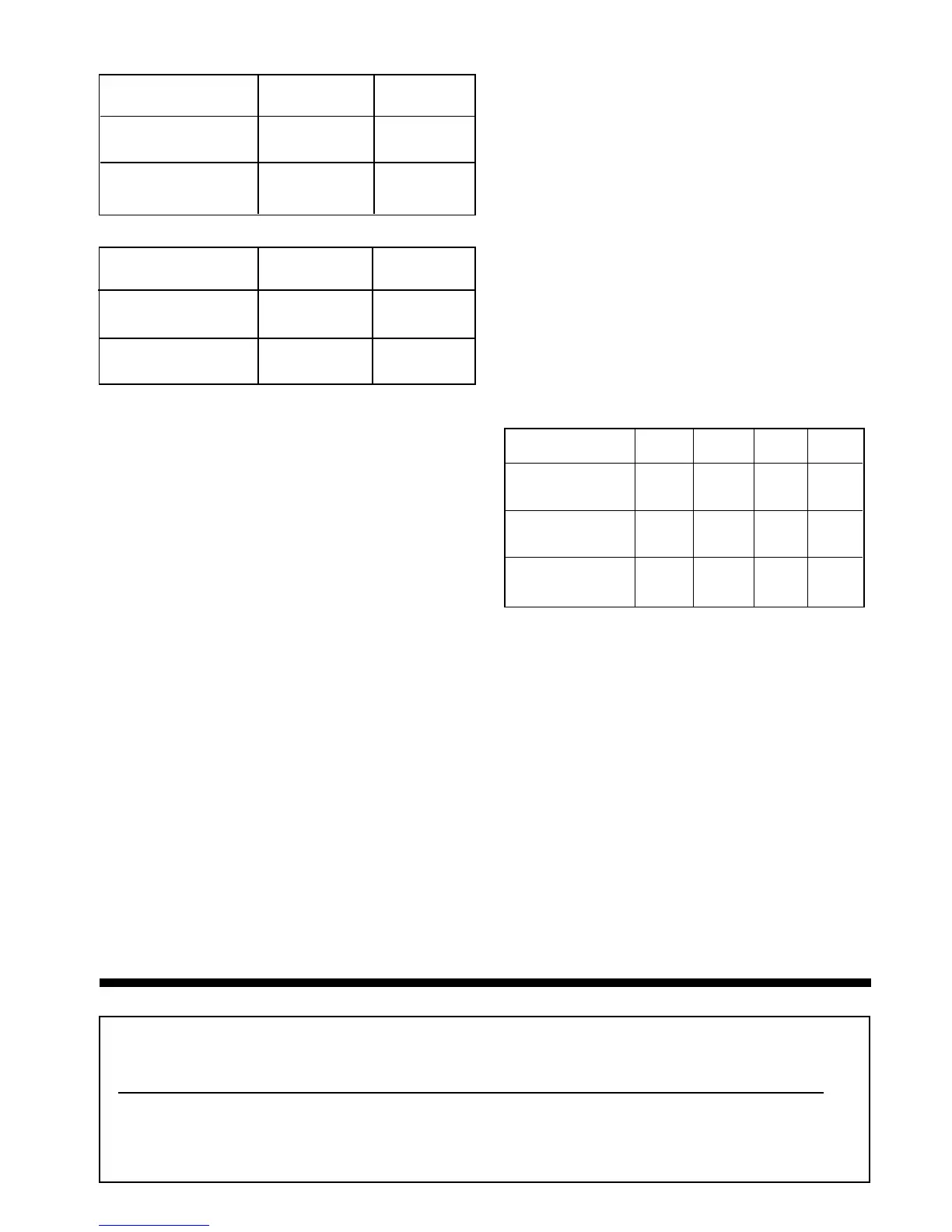

Table 8 - WATER FLOW RATE AND PRESSURE LOSS

Boiler Size RS 30 RS 40 RS 50 RS 60

Boiler output kW 8.8 11.7 14.7 17.6

Btu/h 30 000 40 000 50 000 60 000

Water flow l/min 11.4 15.2 19.0 22.8

rate gal/h 150 200 250 300

Pressure mbar 22.0 20.4 31.5 41.7

loss in w.g. 8.9 8.3 12 6 16.7

ELECTRICAL SUPPLY

Wiring external to the appliance MUST be in accordance with

the current 1. E. E. Wiring Regulations and any local

regulations which apply.

The boiler is supplied for 240 V ~ 50 Hz

Single Phase Fuse Rating is 3 A

The method of connection to the mains electricity supply

MUST facilitate complete electrical isolation of the boiler,

preferably by the use of a fused, unswitched three-pin plug

and a shuttered socket outlet, both complying with the

requirements of BS.1363. Alternatively, a fused double pole

switch, having at least a 3 mm (1/8 in.) contact separation in

both poles and servicing only the boiler, may be used.

The point of connection to the mains should be readily

accessible and adjacent to the boiler, except that for bathroom

installations, the point of connection to the mains MUST be

situated outside of the bathroom.

Note: Where a room sealed appliance is installed in a room

containing a bath or shower then the appliance and any

electrical switch or appliance control utilising mains electricity

should be so situated that it cannot be touched by a person

using the bath or shower.

Position of air vent Air from room/ Air direct

internal space from outside

HIGH LEVEL cm

2

170 85

(in

2

) (27) (14)

LOW LEVEL cm

2

170 85

(in

2

) (27) (14)

Position of air vent Air from room/ Air direct

internal space from outside

HIGH LEVEL cm

2

203 102

(in

2

) (32) (16)

LOW LEVEL cm

2

203 102

(in

2

) (32) (16)

WATER CIRCULATION SYSTEM

The boiler must NOT be used for direct hot water supply. For

the types of system and correct piping procedure see

'Introduction' and Frame 3.

Note: All water connections MUST be made to the boiler TOP

tappings.

The central heating system should be in accordance with

BS.6798 and, in addition, for Smallbore and Microbore

systems, BS.5449.

The domestic hot water system, if applicable, should be in

accordance with the relevant recommendations of BS.5546.

Copper tubing to BS.2871 :1 is recommended for water

carrying pipework.

The hot water storage cylinder MUST be of the indirect type

and should preferably be manufactured of copper.

Single-feed, indirect cylinders are not recommended and

MUST NOT be used on sealed systems.

The appliances are NOT suitable for gravity central heating

systems, with or without additional gravity domestic hot water

supply nor are they suitable for the provision of gravity

domestic hot water requirements above a 181.8 litre (40 gal)

tank capacity, depending on the model.

The hot water cylinder and ancillary pipework not forming part

of the useful heating surface should be lagged to prevent heat

loss and any possible freezing - particularly where pipes run

through roof spaces and ventilated underfloor spaces.

The boiler must be vented.

If venting cannot be done via a flow connection then a

separate vent MUST be fitted by the installer. This does NOT

mean that more than one open vent is required. Other parts of

the system, which may become unavoidably air locked, can be

automatically vented.

Draining taps MUST be located in accessible positions, which

permit the draining of the whole system - including the boiler

and hot water storage vessel. Draining taps should be at least

1/2in. BSP nominal size and be in accordance with BS.2879.

GENERAL

Table 7 - RS 60 AIR SUPPLY

Table 6 - RS 50 AIR SUPPLY

The boiler is supplied fully assembled in one pack ' A' together with one of four packs, B, B1, C and D, containing the flue terminal

appropriate to the wall thickness. Optional extras, if ordered (programmer kit, complete sealed system module and overheat

thermostat kit) are supplied in separate boxes.

PACK 'A' CONTENTS • Installation & Servicing Instructions HARDWARE PACK CONTENTS • Data plate indication

• Complete boiler • User's Instructions • No.14 x 50mm wood screws, • arrow, 1 off

• Wall mounting template • Hardware pack 3 off • Back panels to wall

• Wall mounting plate • Controls pod door • No.10 x 50mm wood screws, 3 off • sealing strip, 3 off

• Cover plate • Wall plug (TP2B - brown), 6 off

INSTALLATION

1 UNPACKING

UNPACKING - BOILER ASSEMBLY

AIR SUPPLY- ELECTRICAL SUPPLY

5

Loading...

Loading...