COMCO IKARUS

Maintenance Manual C42 Series

MaintenanceManual C42-

Series_Issue_VII_18.02.2014.doc

Revison No.:1 77 from 107

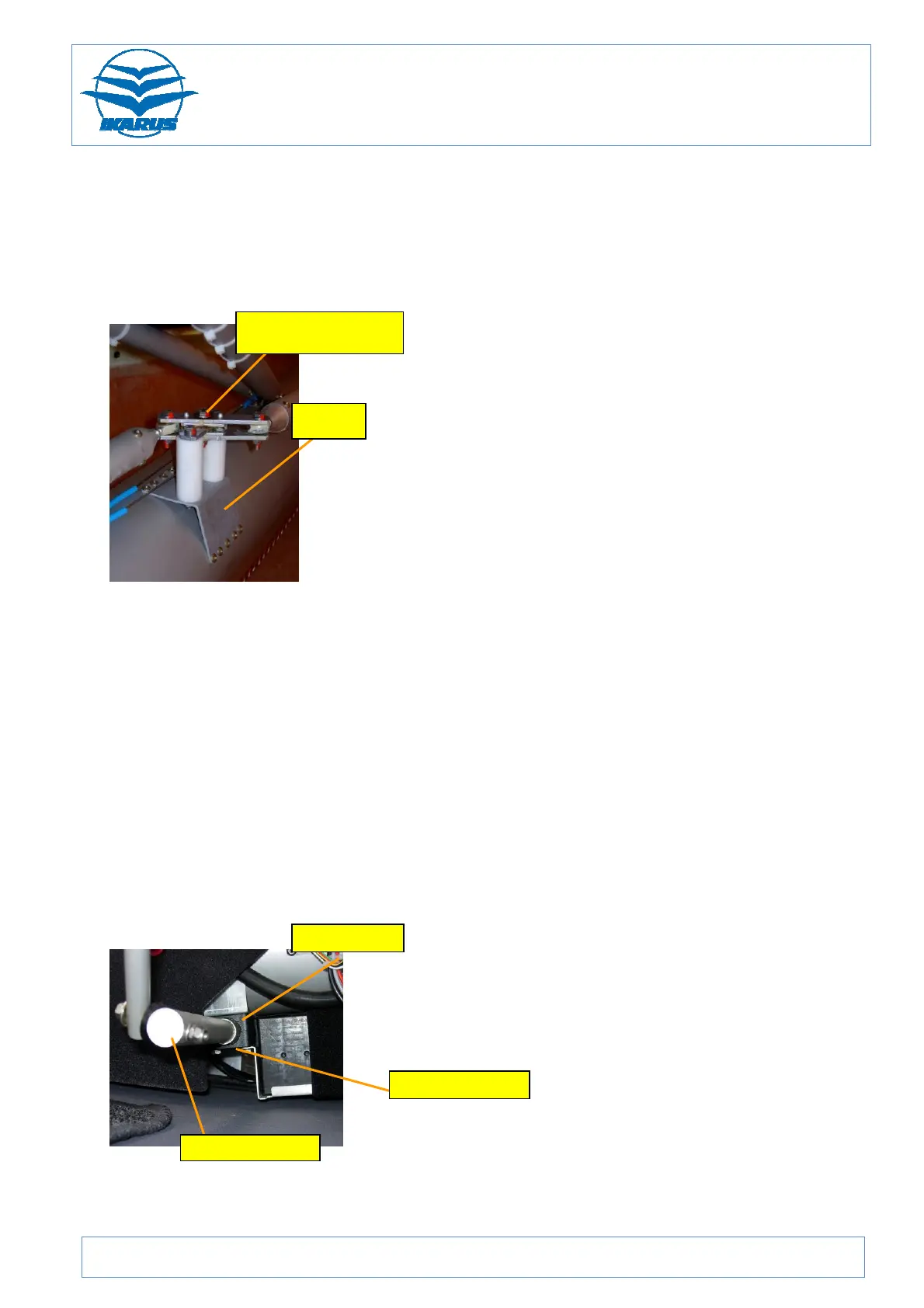

4.3.6.3 Servicing the elevator reversal bellcrank

The following areas in particular must be inspected carefully: the bracket of the

elevator reversal bellcrank for cracks, the rivet connection for proper fit and missing

rivets , the screws at the bracket for proper fit and condition.

Figure 72: Elevator reversal bellcrank

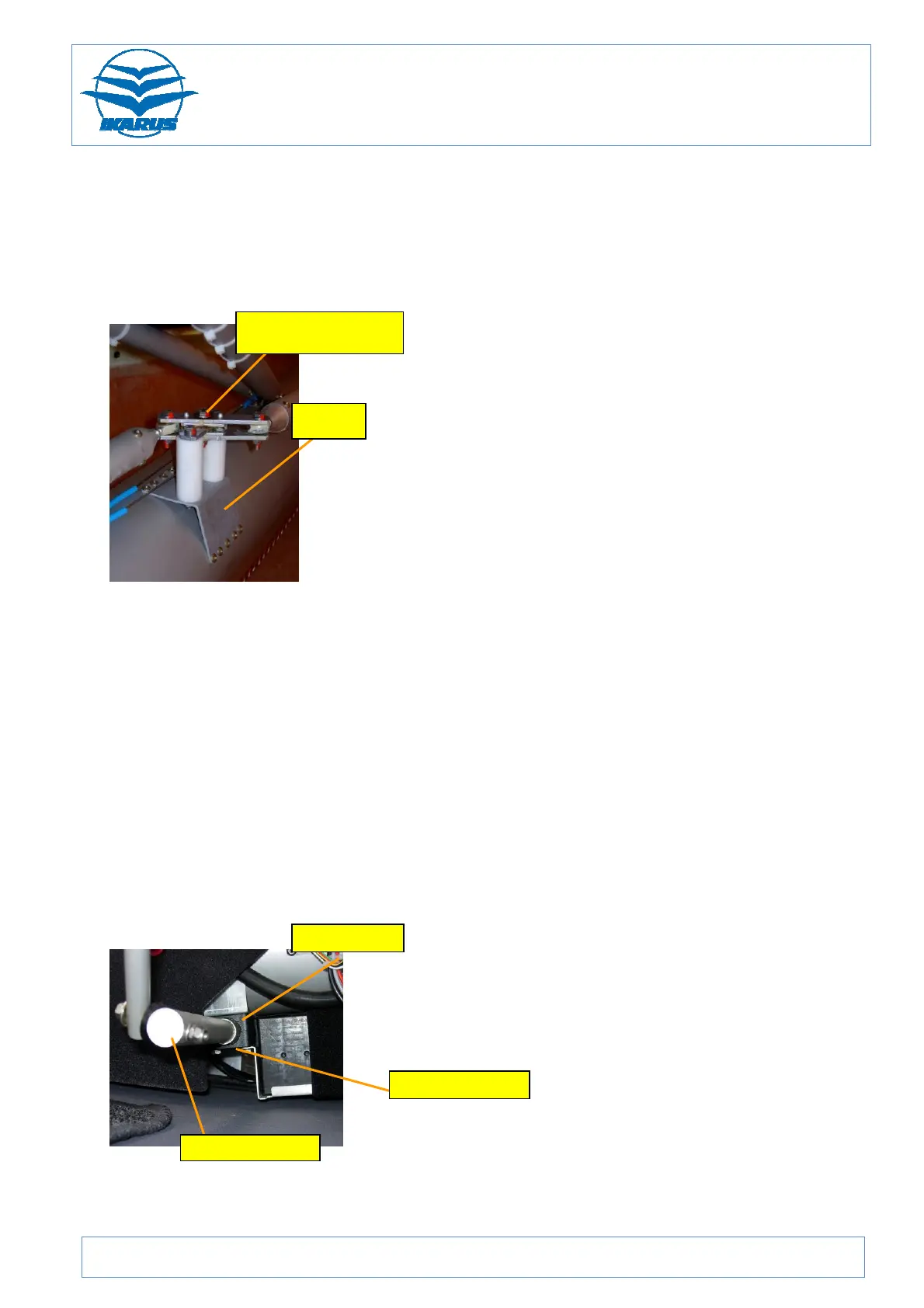

4.3.6.4 Setting the throttle friction

The carburettor throttle valves have tension springs that pull the valves into the full

open position should the throttle cable snap. The moment of the springs on the

throttle valve levers is compensated by the friction of the throttle lever shaft in the

plastic clamps and a tension bungee. Journal bearing friction can be set by the front

attachment screw.

First, the running surfaces of the plastic clamps are greased slightly (journal bearing).

Then the bearing attachment screws are screwed so tight to compensate the

retention moment of the springs. The throttle lever must not be drawn forward by the

springs but it should also not be difficult to move. The correct tension must be

checked in various throttle settings.

Figure 73: Plastic clamp at throttle lever shaft

elevator reversal

fitting

Loading...

Loading...