COMCO IKARUS

Maintenance Manual C42 Series

MaintenanceManual C42-

Series_Issue_VII_18.02.2014.doc

Revison No.:1 93 from 107

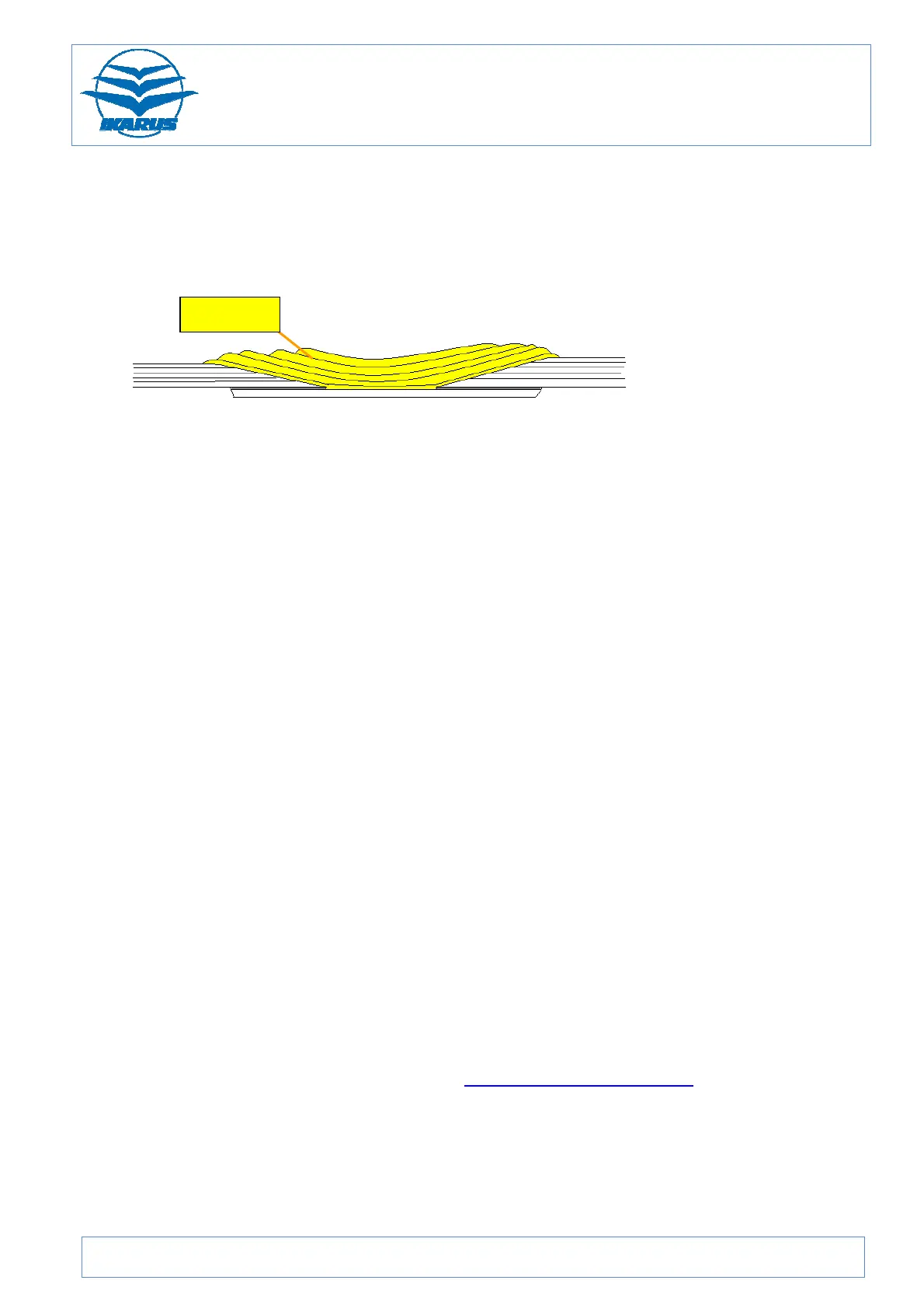

The next step is the repair lay-up. Glass-fibre fabric sections are cut, the top layers

being smaller than the lower layers. The fibre direction of all the layers is the same as

that of the lowest layer. The fabric layers should overlap the repair area by approx.

30-50 mm. The number of layers required depends upon the kind of repair material

used and the scale of the damage.

Figure 87: New laminate lay-up

The repaired area is then covered with resin and the largest fabric layer placed in

fibre direction on the undermost fabric layer. Using a brush the layer is then

completely soaked with resin. Further fabric layers are applied and completely

soaked in the same manner.

Usually, no resin must be applied to the final fabric layer. Dabbing with a brush

ensures that sufficient resin is absorbed from the lower layers. Finally, a PE foil is

placed over the repaired area and the laminate is allowed to harden. The hardening

process can be assisted through uniform heat application (approx. 60°C) using, for

example, a heating foil. Once the hardening process has been completed (standing

fibres can be broken off), the foil is removed and the repair area sandpapered (grain

180) to ensure a smooth transition at the edges. The repair area should be a few

tenths of a millimetre deeper than the surrounding area. If the area is too deep, it can

be filled.

The repair area can now be varnished.

Original coating: polyester gel coat (white).

5.6 Electrical repairs

Faulty electrical components may only be replaced by new original spare parts which

may be ordered from an IFC / ISC or directly from COMCO IKARUS., Circuit

diagrams are to be found in the appendix to this manual.

Faults must be reported to COMCO IKARUS.

5.7 Ikarus Flight Centres

A list of IFCs is to be found on our website http://www.comco-ikarus.de

new lay-up

Loading...

Loading...