COMCO IKARUS

Maintenance Manual C42 Series

MaintenanceManual C42-

Series_Issue_VII_18.02.2014.doc

Revison No.:1 92 from 107

5.5 Repairing the glass-fibre / carbon-fibre skins

In contrast to many sailplanes and other micro-light aircraft, the glass-fibre/carbon-

fibre parts of the C42 rarely carry loads as they are mainly fairings. Damage to

glass-fibre/carbon-fibre parts thus has no effect on the strength of the aircraft. This is

also the reason repair work on the glass-fibre/carbon-fibre parts of the C42 is

relatively simple. One must, however, be careful that repair work does not lead to an

increase in mass or a change in the centre of gravity of the aircraft.

Normal glass-fibre/carbon-fibre repair kits may be used. The instructions

accompanying the kit must be followed. If large-scale damage has been done,

replacement of the damaged part should be considered as original glass-

fibre/carbon-fibre spare parts for the C42 are relatively inexpensive. Large-scale

repair work is thus not particularly practical. The IFC / ISC provide information about

spare parts.

During repair work a minimum temperature of 20°C is necessary to ensure that the

laminate hardens properly. Higher temperatures will accelerate the hardening

process. Before beginning with repair work, clean the repair area thoroughly. Then

grind the damaged area and remove the adjacent coating (polyester gel coat) using,

for example, 60-80 grain sandpaper. The fibre layers should be visible 30-50 mm

around the damaged area. If possible, enough of the damaged laminate should be

left to act as a mould for the repair work. If this is not possible, a base for laminating

can be formed using a wide adhesive tape and a thin sheet (glass-fibre, sheet metal,

etc.). The sheet must be covered with a separating agent (e.g. packing tape) so that

it can be removed after laminating.

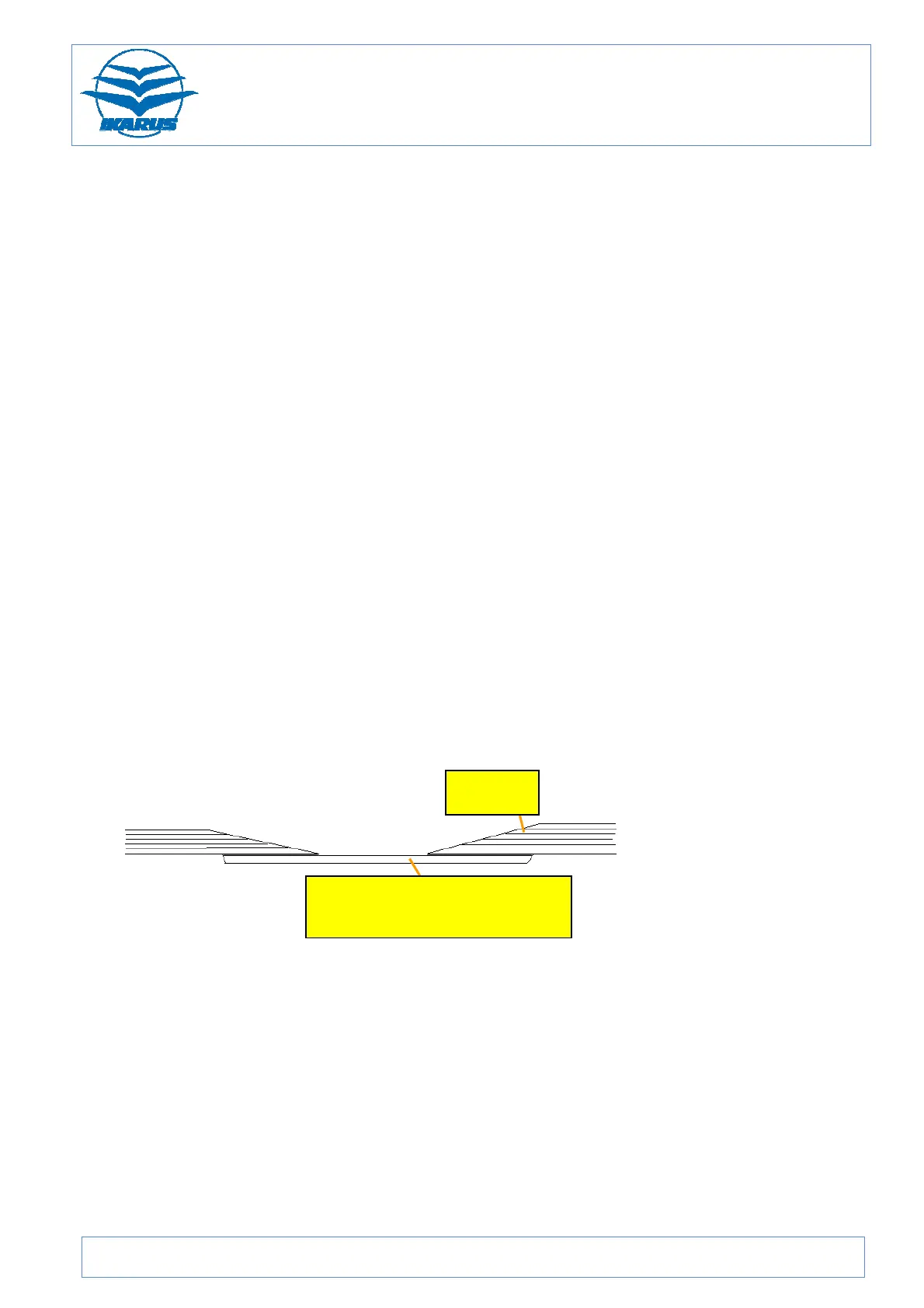

Figure 86: Grinding of laminate

grinded

auxiliary laminating base plate (sheet

metal, plastic, glass-fibre) mounted on

the inside with adhesive tape

Loading...

Loading...