-71-

Introduction

5.2 Selecting and Making Cables

5.2.1 Selecting Cables

Applicable Module Cable Lug Model American standard/AWG Crimping Plier

Power module Fork lug TNS1.25-4 22-16

RYO-8

YYT-8

16-channel DI/DO module Fork lug TNS1.25-3 22-18

RYO-8

YYT-8

32-channel DI/DO module Tubular lug GTVE10006 18 YAC-5

AI/AO module Fork lug TNS1.25-3 22-18

RYO-8

YYT-8

Temperature module Fork lug TNS1.25-3 22-18

RYO-8

YYT-8

The rated cable temperature is above 75 ℃ .

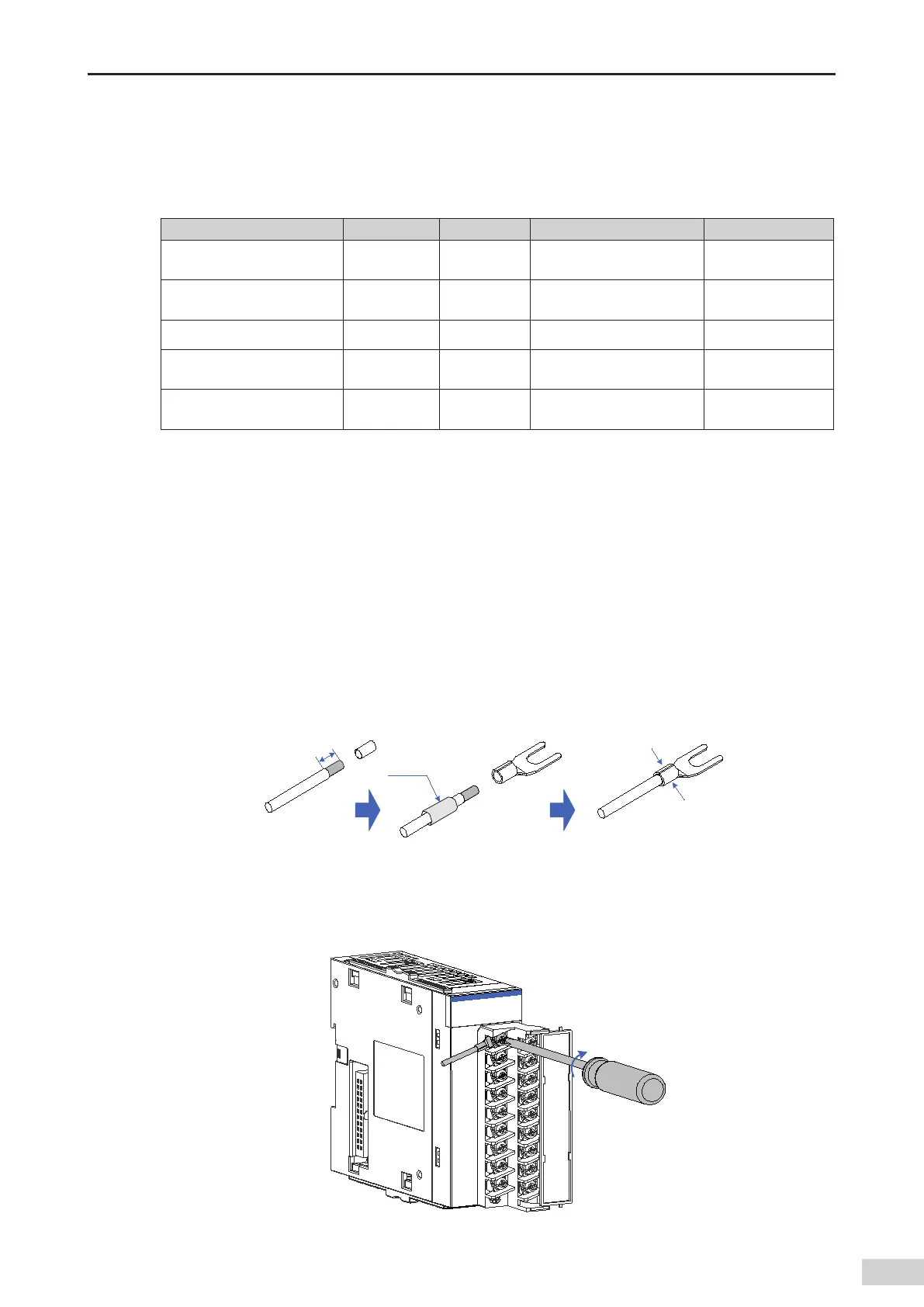

5.2.2 Making Fork-lug Cables

The procedure for making a fork-lug cable is as follows:

1) Peel o the insulation coating by 6 mm.

2) Pass the cable through a cable marker sleeve of proper size.

3) Insert the exposed end of the cable into the round hole of the lug and use the recommended

crimping plier to crimp the hole.

4) Insert the lug into a 20 mm-long heat-shrinkable sleeve (Φ3 )

,

cover the copper part of the lug

,

and

then apply heat to make the heat-shrink sleeve shrink.

6

mm

Cable marker

sleeve

Crimp with

crimping pliers

Figure 5-7 Making a fork-lug cable

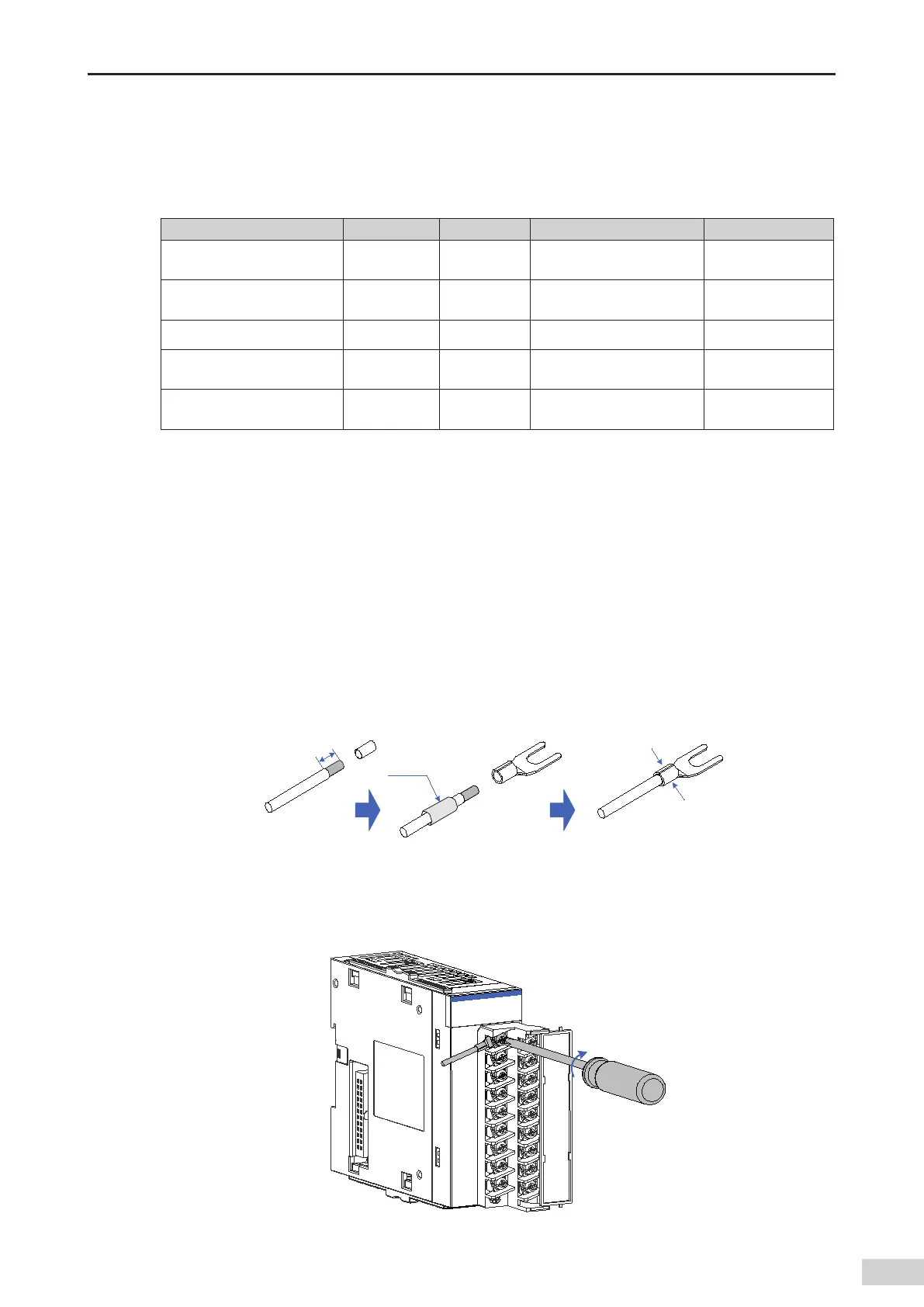

5) Insert the lug into the terminal block and use a screwdriver to tighten it. The applied torque cannot

exceed 0.8 N·m.

Figure 5-8 Connecting a cable to the terminal block

Loading...

Loading...