37

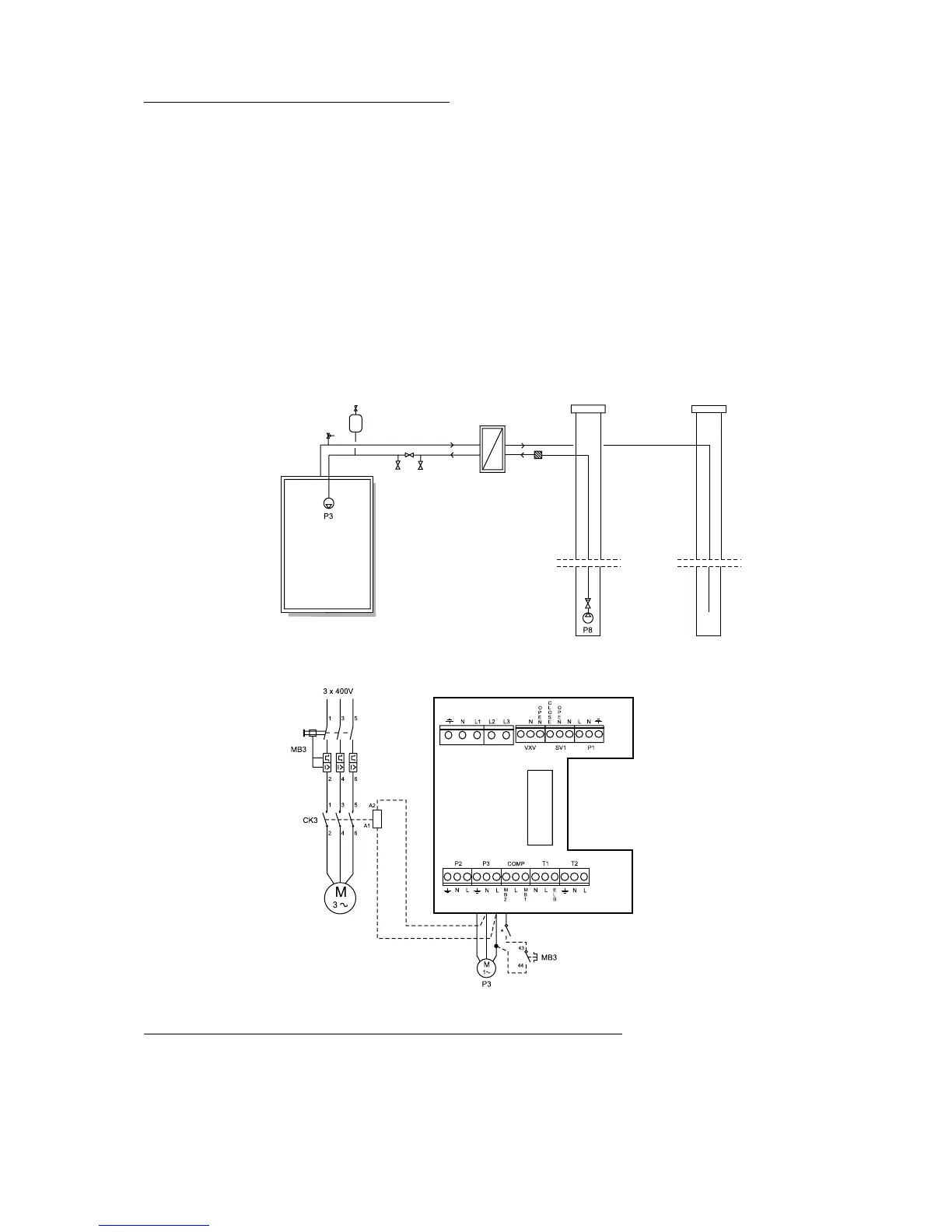

Intermediate heat exchanger

The flow in the exchanger must be

counterflow. The pipe from the well

is connected to the bottom of the

exchanger so that the flow goes

upwards.

Heat pump

Water source Recharge well

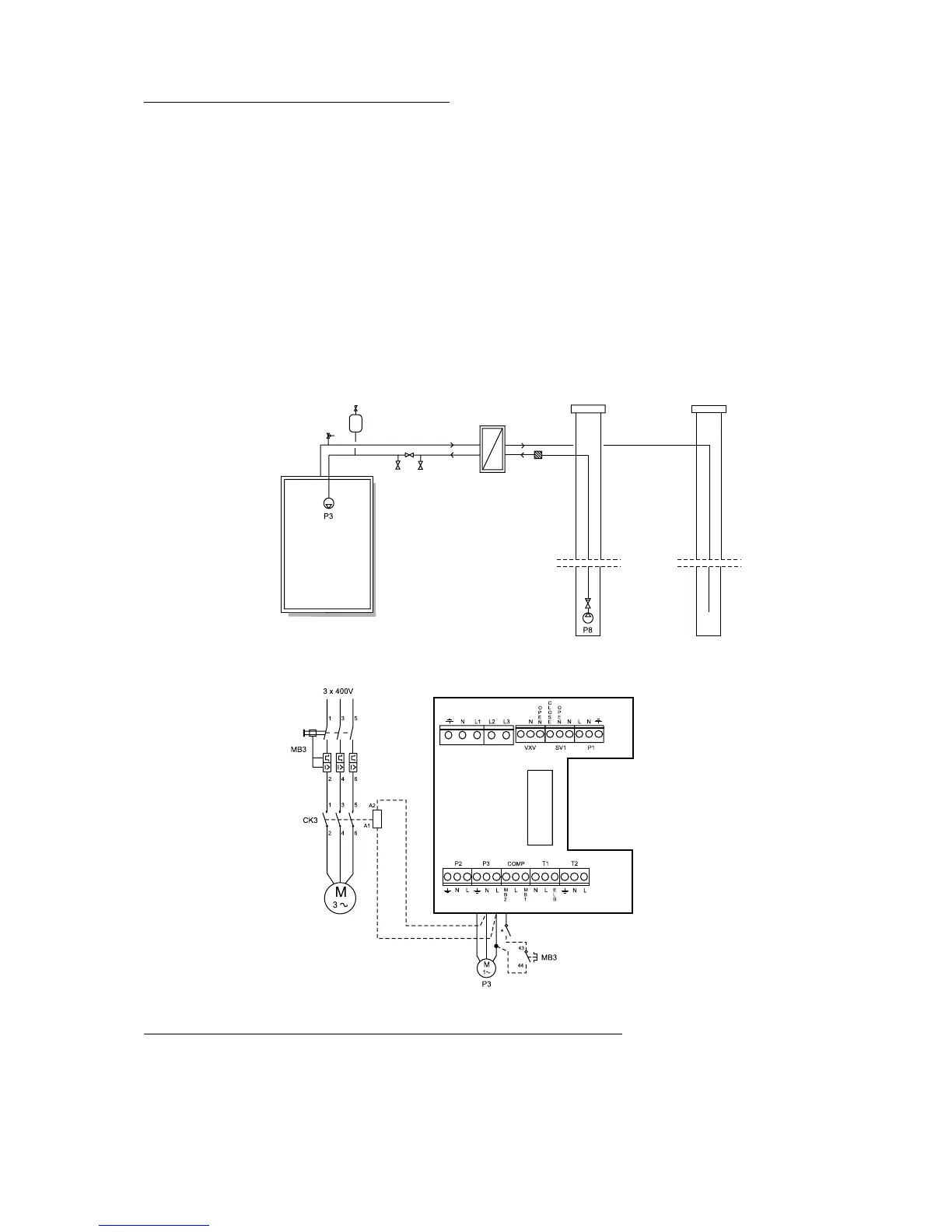

* Model 11 has a built-in motor

cutout in the pump.

Models 5-9 have a clamp mounted

between L and MB2.

Terminal card

Connecting to the heating system

General

Installation must be carried out by an authorised installer and must follow the current rules and recom-

mendations of IVT. The pipework must be flushed before the heat pump is connected to protect the

heat pump from contaminants.

Safety

valve

Filling unit

P8

Ground

water

water pump

Ground water system

Application:

Systems using ground water are equipped with an intermediate heat exchanger to eliminate the risk for

freezing. A pump with a non-return valve is placed in the bore hole that via a hose pumps the water to

the intermediate exchanger and then back to an injection well. The circuit to the heat pump is installed

in the normal way with a filling unit and safety valve. The circuit should contain around 29 volume

percent antifreeze (ethanol or ethylene glycol) which corresponds to around -15

o

C freezing point.

Electrical connections:

The ground water pump is connected to 3 x 400 volt with a motor cutout and a contactor. Power to

contactor CK3(230V) is fetched from terminals L and N (P3) in the heat pump. The auxiliary contact

for motor cutout MB3 is series connected with the MB2 alarm. In this way the ground water pump

starts and stops with the heat pump’s heat transfer fluid pump and during motor cutout MB3, the heat

pump stops and the heat transfer fluid pump alarm shows in the alarm display. NOTE: Single-phase

pumps should always be connected with a contactor. It should never be connected to the P3 outlet in

the heat pump.

Filter

Exp

Loading...

Loading...