62

Technical information

Important points to check

During the first period after commissioning you should pay special attention to the pressure levels in

the heating system and heat transfer circuit. It might need filling up.

The factory setting of the motor cutout is based on a value under the hot water pressure and stable

voltage. Because of the various voltages in the electric network the recommended settings are not

always suitable and can therefore need adjusting from time to time. This is best achieved using a clip-

on ammeter during hot water operation.

For the heat pump to perform at its best, it is important to check the flow on the hot and cold side of

the heat pump. Usually, the heat transfer fluid pumps each have a speed selector switch. These must be

set correctly for the pressure drop in the systems. A recommended temperature difference over the heat

pump on the cold side is between 2-3°C and on the hot side between 7-10°C. The nominal flows

specified in Technical Specifications give a difference of 3°C to 7°C at operating mode 0/45°C. You

can check this with the help of the sensor temperatures in line three of the control panel.

It is also important that the flow in the radiator system exceeds the flow across the heat pump. If this is

not the case, the heat pump flow goes back via the bypass to the heat pump return, which may case the

heat pump to trip for high return temperature. The flow through the radiator system must be high

enough to ensure that the entiresurface of the radiators is kept hot. This maximises the heat-radiating

surface and so keeps down the flow temperature from the heat pump.

After testing, vent the system again and top up with cold water if necessary.

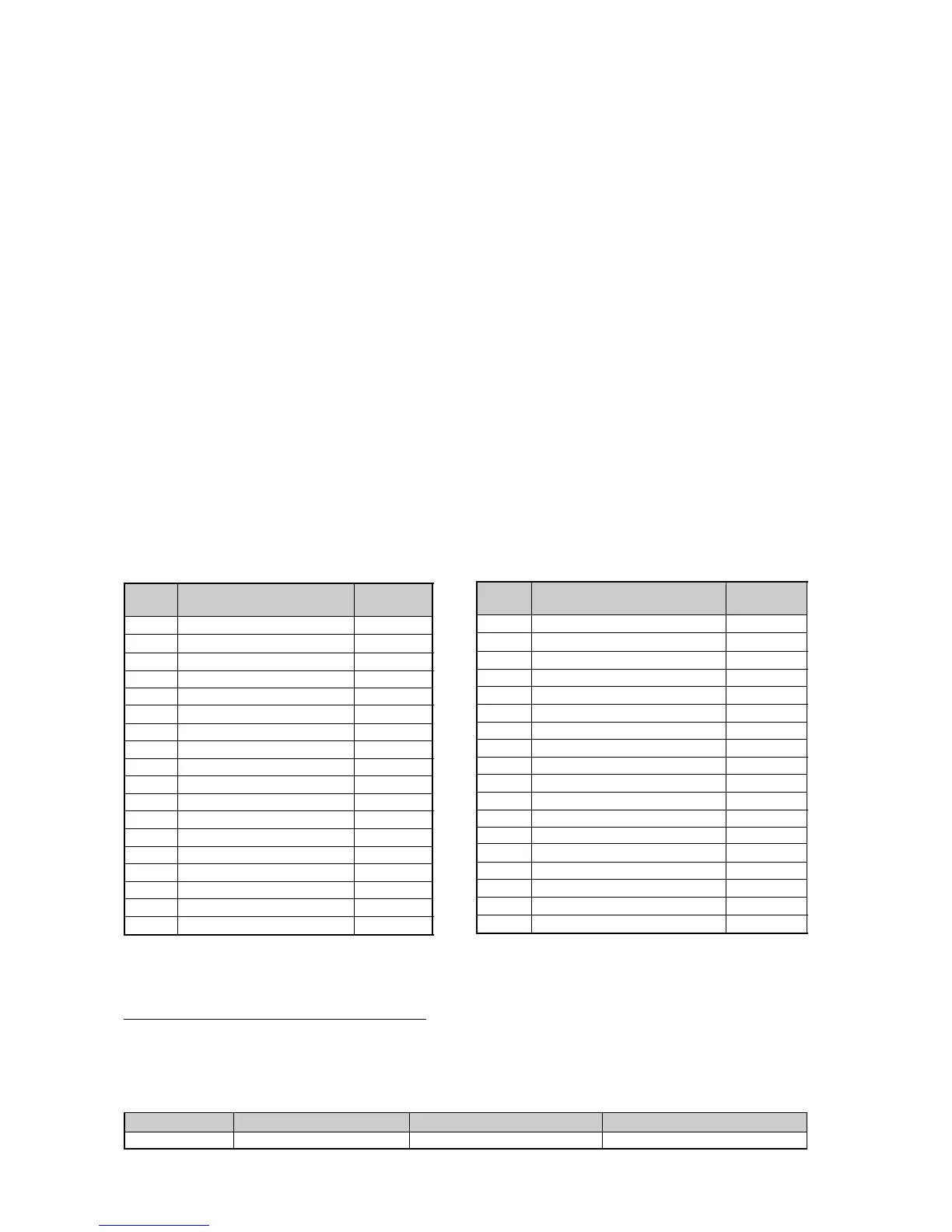

Table of factory settings

The table shows the factory settings of all the settings that can be changed by the installer.

P2.3 Setting of DHW temp. 45°

P2.4 Setting of DHW hysteresis 5°

P4.1 Clock setting HP not active

P4.1.1 Setting level HP 0°

P4.2 Clock sett. add. heat not active

P4.3 Clock setting DHW not active

P5.1 Select operating case A

P5.2 Conn. cap. electric add. heat. 2/3

P5.4 Only add. heat Off

P5.5 add. heat yes/no 5.5 yes

P5.7 External controls 0

P5.10 Operating option, P2 On

P5.11 Operating option, P3 Off

P8.1 Add. heat timer 60 minutes

P8.3.1 Time delay SV1 30 minutes

P8.3.2 Time delay for stop boiler 60 minutes

P8.3.6 Delay time interval SV1 1 minute

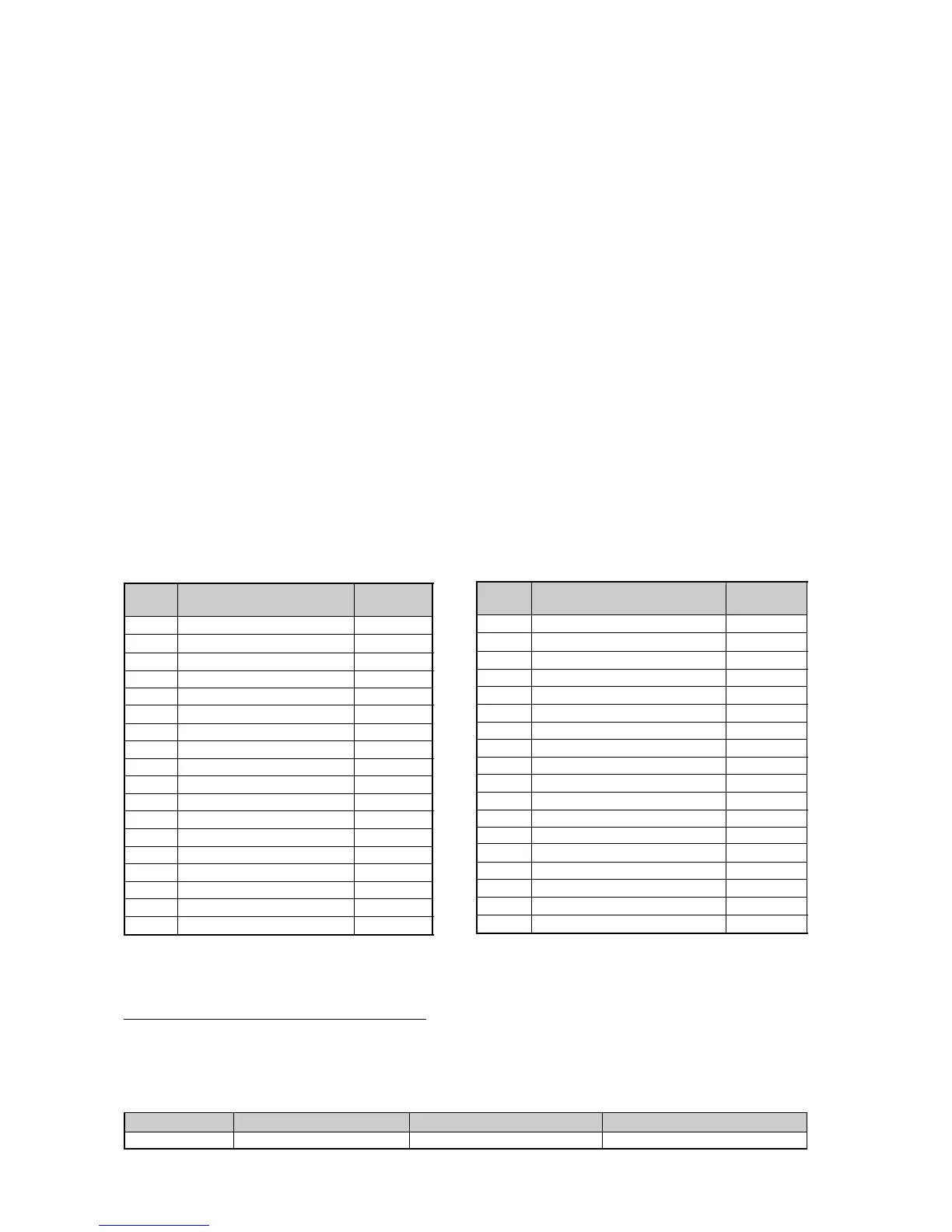

Table of selected output in display 5.2

The table shows the output available for various selections in display P5.2. If e.g. have chosen 2/3 the

output is in two steps. The first step is 3.0kW and the second is 6.0kW.

Model

C4/E5-C11/E11

Max output at 1/3

3.0 kW

Max output at 2/3

6.0kW

Max output at 3/3

9.0 kW

P1.1 Temp incr/decr 4

P1.2 Temp fine-tune 0°

P1.3 Heat curve adjust 0°

P1.4 Heat curve hysteresis. 5°

P1.5 Mix. valve incr/decr 4

P1.6 Mix. valve fine-tune 0°

P1.7 Mix. valve curve adjusting 0°

P1.8 Mix. valve curve neutral zone 3°

P1.9 Mixing curve max temp. 60°

P1.10 Room temperature 20°

P1.11 Room sensor influence 5

P1.12 Holiday function 0 days

P1.13 Remote control heating not active

P1.14 Summer disconnection 18°

P1.16 Return thermostat setting 48°

P1.17 Return thermostat hysteresis 5°

P2.1 Additional hot water 0 hours

P2.2 Interval for DHW peak not active

Factory

setting

Position Setting

Factory

setting

Position Setting

Loading...

Loading...