Function and operation

Vent 402 – 6721815546 (2021/03)

17

6.5 Minimum indoor temperature

NOTICE

Risk of defrosting problems or high energy consumption!

At low indoor temperatures in combination with low fan speeds,

defrosting problems or low pressure alarms can arise. To avoid this,

follow the recommendations below for minimum indoor air temperature

setting.

Do not set room temperature to lower than 18ºC if the airflow is set

at 70m

3

/h.

Do not set to a temperature decrease at night or holidays which will

cause the room temperature to drop below 18ºC if the airflow is set

at 70m

3

/h.

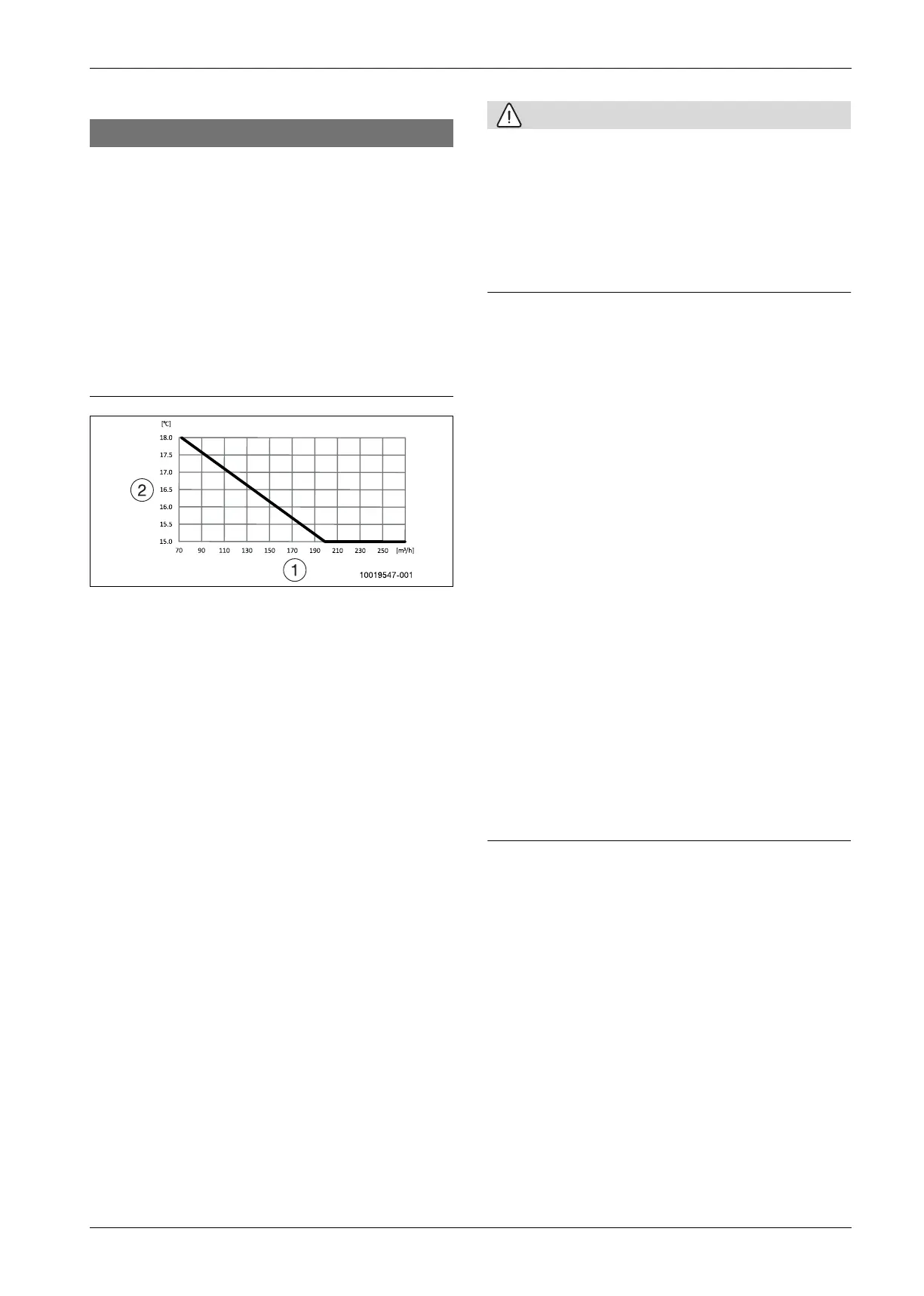

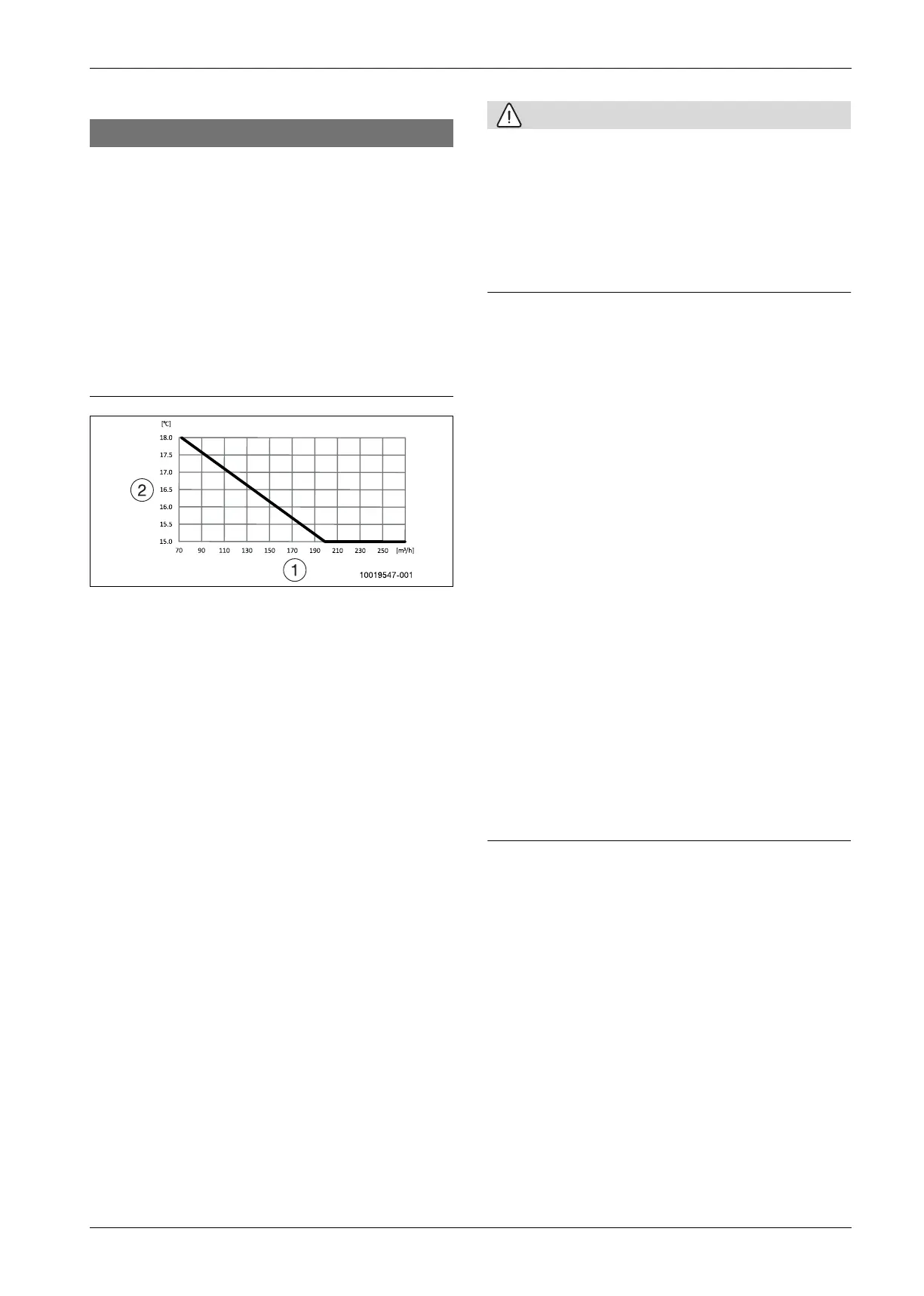

See the diagram for setting the lowest temperature in relation to

airflow.

Notify the user about the lowest indoor temperature for economic

operation.

Fig. 20 Lowest incoming air temperature for compressor operation

[1] Airflow

[2] Incoming air temperature (indoor temperature)

6.6 Adjustment of air flow / ventilation

This is performed by ventilation technicians for adjusting for correct air

flow, see ventilation drawing.

Adjust the ventilation as per the sizing information and settings in the

user interface (see table 7.7.1).

6.7 Function test

Vent the system (see Chapter 6.3).

Check the system's active components using the function check (

Chapter 8.4).

– Check that the primary pump PC0 works properly. To do this, set

PC0 prim heating pump to On.

– Change the primary pump speed with the variable PC0 speed and

check that the circulation pump reacts accordingly. At higher

speeds, the vibrations from the circulation pump become

stronger. To get a better feel for the pump operation, the speeds

70% and 100% can be compared to each other.

– Check that the heating circuit pump PC1 works properly. To do

this, set PC1 htg circ pump HC1 to On and check that the pump

LED lights green (and does not flash).

– Check that the 3-way valve works smoothly. Switch VW1 HW 3-

way valve between Off (heat) and On (DHW). The 3-way valve

should then change its position.

– Check that the compressor works without problems. To do this,

set Compressor to On. Check that the compressor is running. If

the compressor is switched off, it should not (be able to) turn it on

again immediately. If you turn the compressor OFF using Function

test, wait 10 min. to turn it back on again.

– Check that the electric heater works without problems.

CAUTION

Heat pump overheating!

Proceed carefully. The heating circuit valves must be open. To prevent

the heat pump from superheating, ensure that the temperature in the

primary circuit is below 40 °C.

Make sure that the value for TC3 current cond. temp, TC1 primary

supply temp and TC0 return temperature is below 40 °C. Input

signals infoTo check these temperatures, select .

To cool down the primary circuit turn both circulation pumps ON at

maximum speed, as described in the list above.

Turn on the electric heater's first step; set Auxiliary heater step 1 to

On. Use a voltage meter to check whether there is voltage in the

contactor K1 (upper contactor) on sockets 2T1, 4T2 and 6T3.

Disconnect again immediately. To ensure that the contactor works

without problems, the sockets 2T1, 4T2 and 6T3 must be checked

after the shutdown. There must be no voltage.

Turn on the second stage of the electric heater; set Auxiliary heater

step 2 to On. Use a voltage meter to check whether there is voltage in

the contactor K2 (lower contactor) on sockets 2T1, 4T2 and 6T3.

Disconnect again immediately. To ensure that the contactor works

without problems, the sockets 2T1, 4T2 and 6T3 must be checked

after the shutdown. There must be no voltage.

Check that the fan works without problems. Change the fan speed in

the menu Service > Heat source settings > Heat pump > PL3 fan

speed and check that the fan reacts accordingly.

Check that there is a demand for heat or hot water.

To generate a heat energy demand, raise the set point for the room

temperature. Press the heating icon on the display to do this. Note

that the heat pump operation does not start immediately. Wait at

least 10 minutes, to make sure that the heat pump has started to heat

up the heating system.

-or-

In order to generate a demand, draw off enough hot water so that the

tank cools down.

Check that the heat pump starts and that no alarm is activated.

6.8 System handover

Explain to the customer how the user interface and the accessories

work and how to operate them.

Inform the customer about the selected settings.

7 Function and operation

7.1 Connection principle

This principle is based on floating condensation and an integrated boost

from the electric heater. Via the control panel, the heat pump is regulated

according to the set heating curve. If the heat pump's heat output is not

sufficient to heat the house, the auxiliary heater starts automatically and

produces the desired temperature in the house together with the heat

pump. While the hot water cylinder is heating up, the heat system's heat-

regulated operation is temporarily disconnected by a 3-way valve. When

the hot water tank is heated, the heating system's heat-regulated

operation continues.

7.2 Anti-seizing

In summer mode, the control device ensures that key components such

as the circulation pump, exchange valve and any mixing valves

incorporate anti-seizing.

7.3 Radiators combined with underfloor heating

Where there is a combination of, e.g. underfloor heating and a radiator

system in which two different supply temperatures are required, an

Loading...

Loading...