S5 Workshop Manual Engine

Notes:

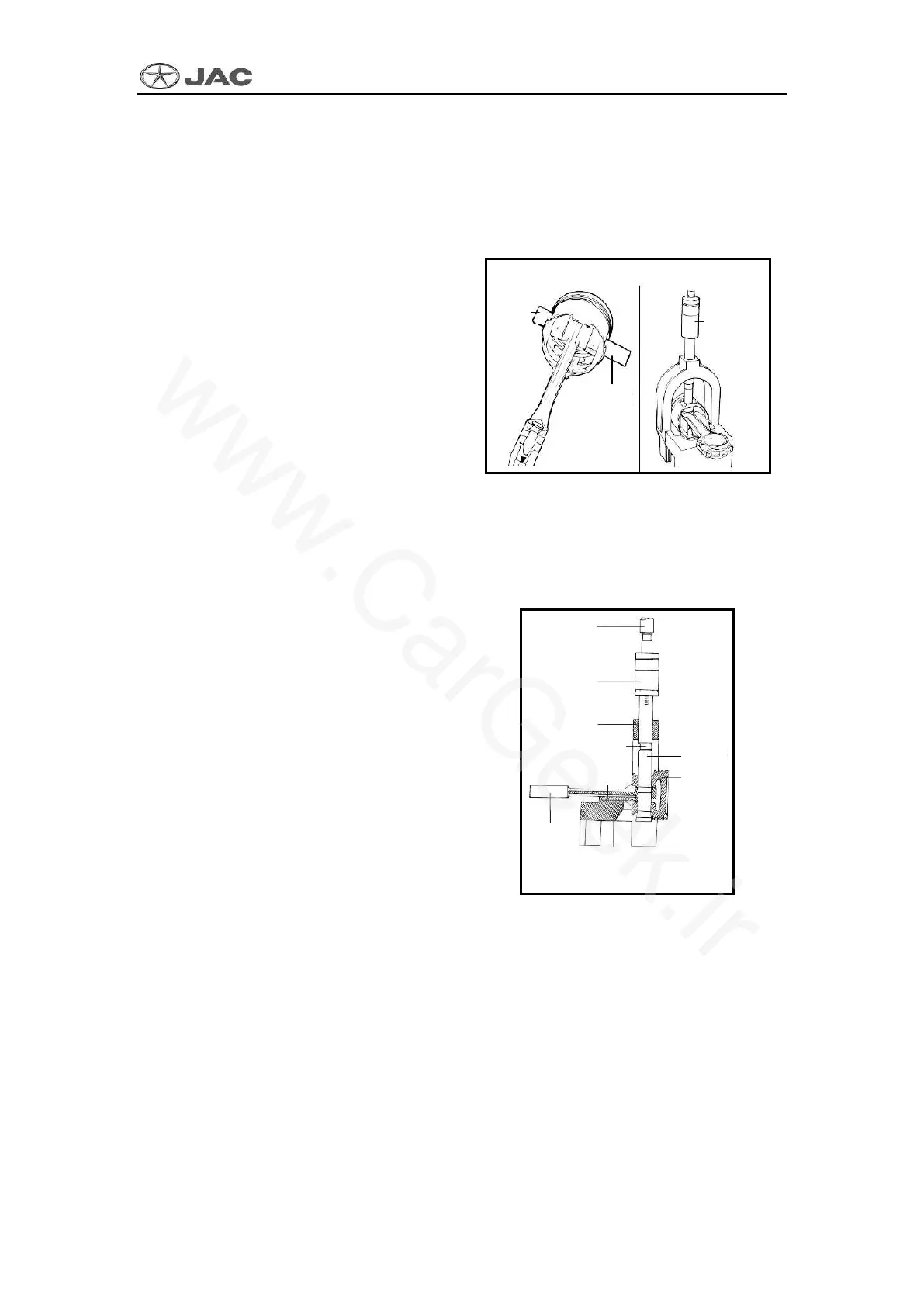

■Pin guide column should be aligned with the centre of connecting rod through

piston. If it is installed properly, piston guide column is just located under the centre

of the hole in tool arch arm and evenly placed on the fork piece. If wrong size of pin

guide column is used, piston and pin can't be aligned with the support.

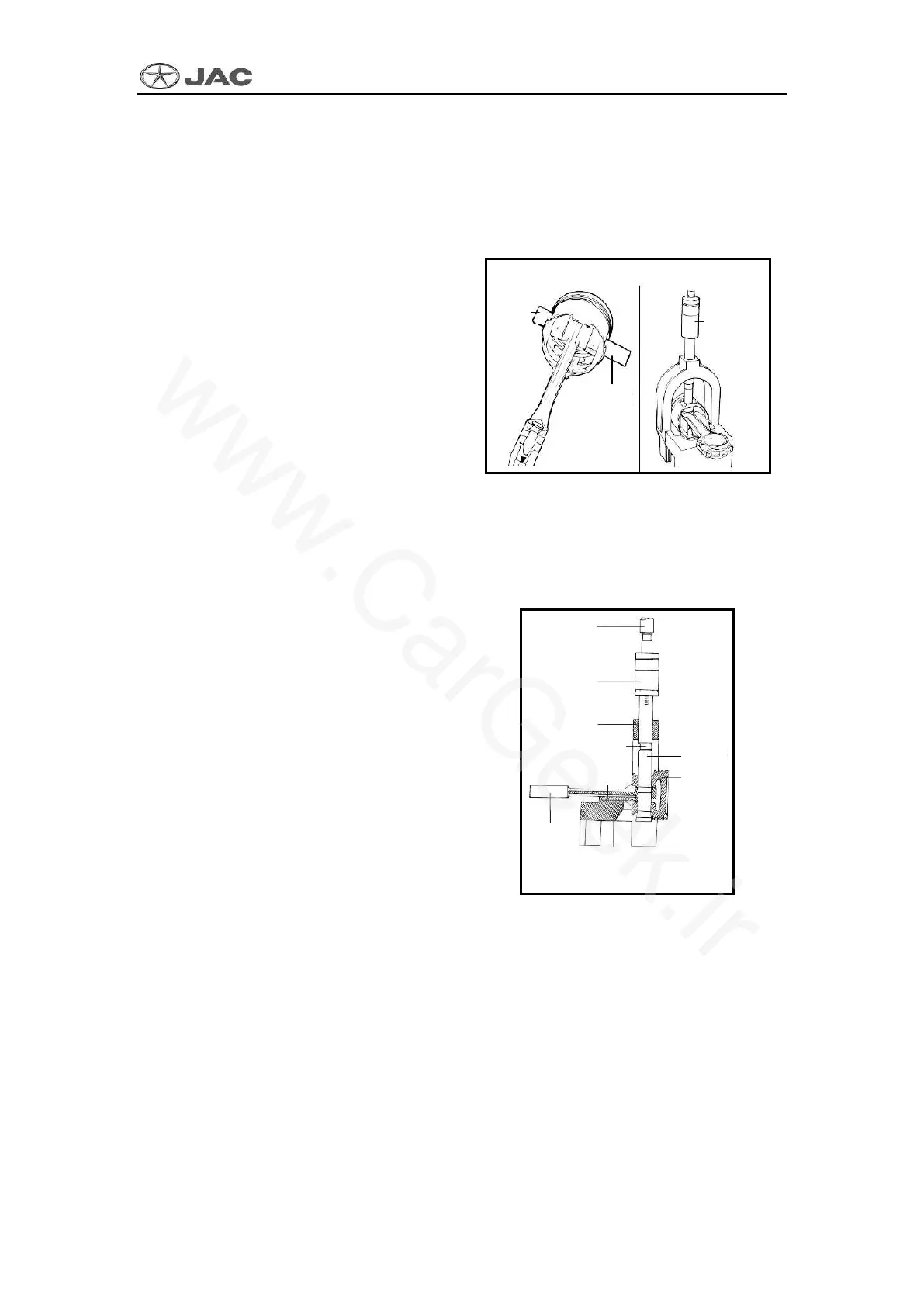

7) Insert installer tool into support arch arm hole, and use a hydraulic press to exert

pressure to piston pin, to let it go through the small end of connecting rod. Continue to

exert pressure until the pin guide column can fall freely and installer tool is just

aligned with the top of arch arm.

Notes:

■ When installing centre shaft lining, the

pressure exerted on the arch arm should

not exceed 1250 ± 500 kg/cm

2

.

3. Inspection

1) Piston and piston pin

Inspect whether each piston has damage, scratch, abrasion and other defect.

Replace the defected piston.

Inspect whether each piston ring is broken, has damage and abnormal abrasion.

Replace the defected piston. When it is required to replace piston, all its rings should

also be replaced.

Universal fork type

inserting piece

Loading...

Loading...