15 - 5

Descriptions (cont'd)

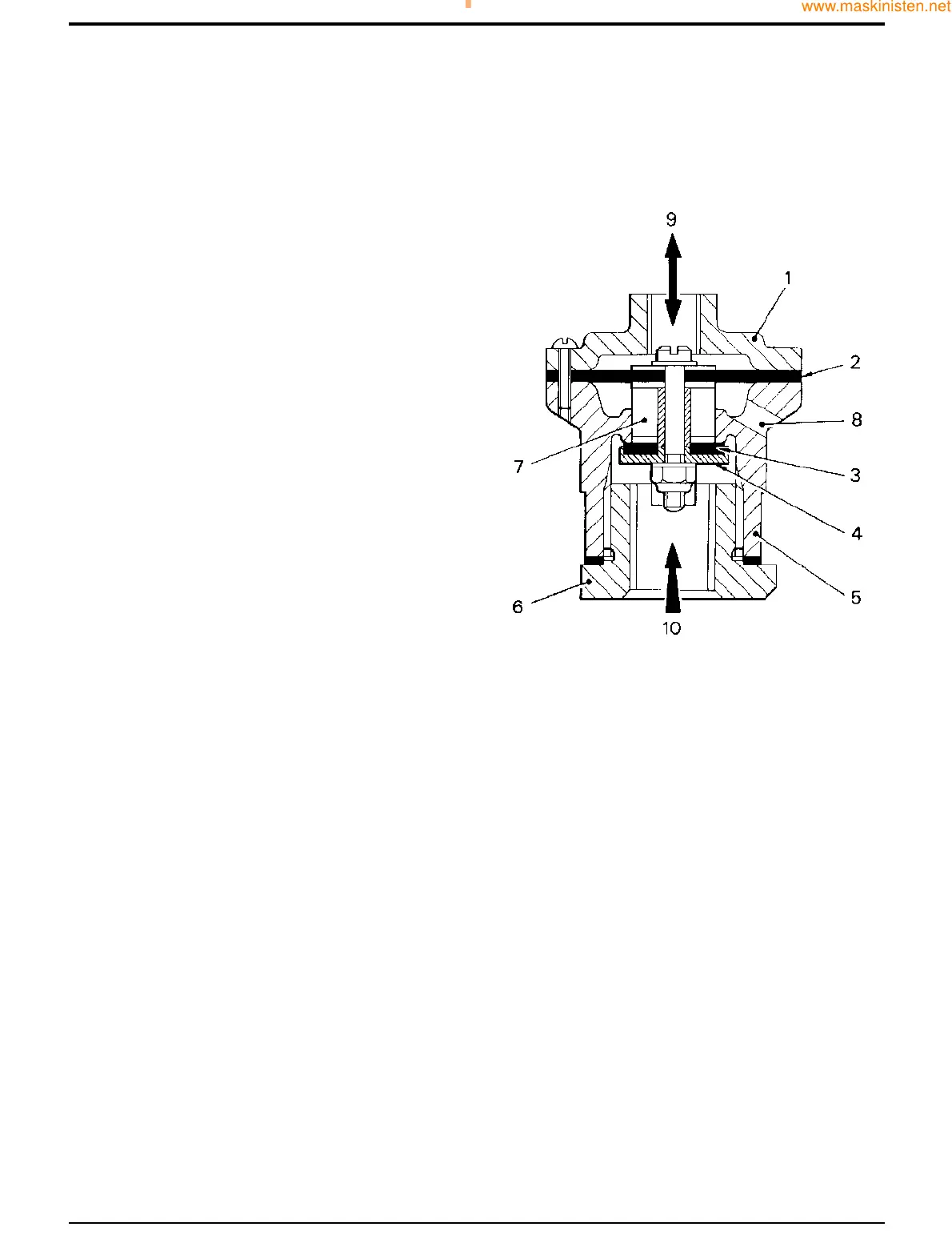

Blow Down Valve

The blow down valve is situated on top of the receiver. It

operates automatically to release all air pressure within the

system on shut-down, thus ensuring that the plant is not

started against delivery pressure.

The valve consists of a body 5 which contains a fluted valve

guide 7, valve 4 and valve seating washer 3. The valve

components are attached to a diaphragm, and the whole is

enclosed by a cap 1 at one end and a screwed cover 6 at

the other.

When the plant is running, a depression is created within the

unloader body which is applied to the top of the diaphragm

2 via inlet 9. Receiver air pressure 10 acts simultaneously

against the underside of the valve 4 and washer 3. The

washer is therefore retained firmly on its seat thus

preventing the escape of receiver pressure through ports 8

in the upper portion of the valve body.

On shut-down the delivery cocks are first closed, then the

engine is stopped. The residual pressure in the receiver

builds up within the unloader body (the unloader valve now

acting as a non-return valve as described on page A/15 - 4

and is applied to the top of diaphragm 2.

This pressure on the large area of diaphragm 2 is sufficient

to overcome the receiver pressure acting on the smaller area

of valve 4, therefore the washer 3 is lifted from its seat so

allowing the pressure still in the receiver to escape to

atmosphere through ports 8.

Section A Attachments

9803/7130

Section A

15 - 5

Issue 1

Airmaster Compressor

S211980

Loading...

Loading...