5 - 10

Routine Maintenance (continued)

Safety Valve

!!

WARNING

Fine jets of air/oil at high pressure can cause injury. Do

not use your fingers to check for leaks. When checking

the safety valve operation/setting always beware of

escaping air/oil mixture.

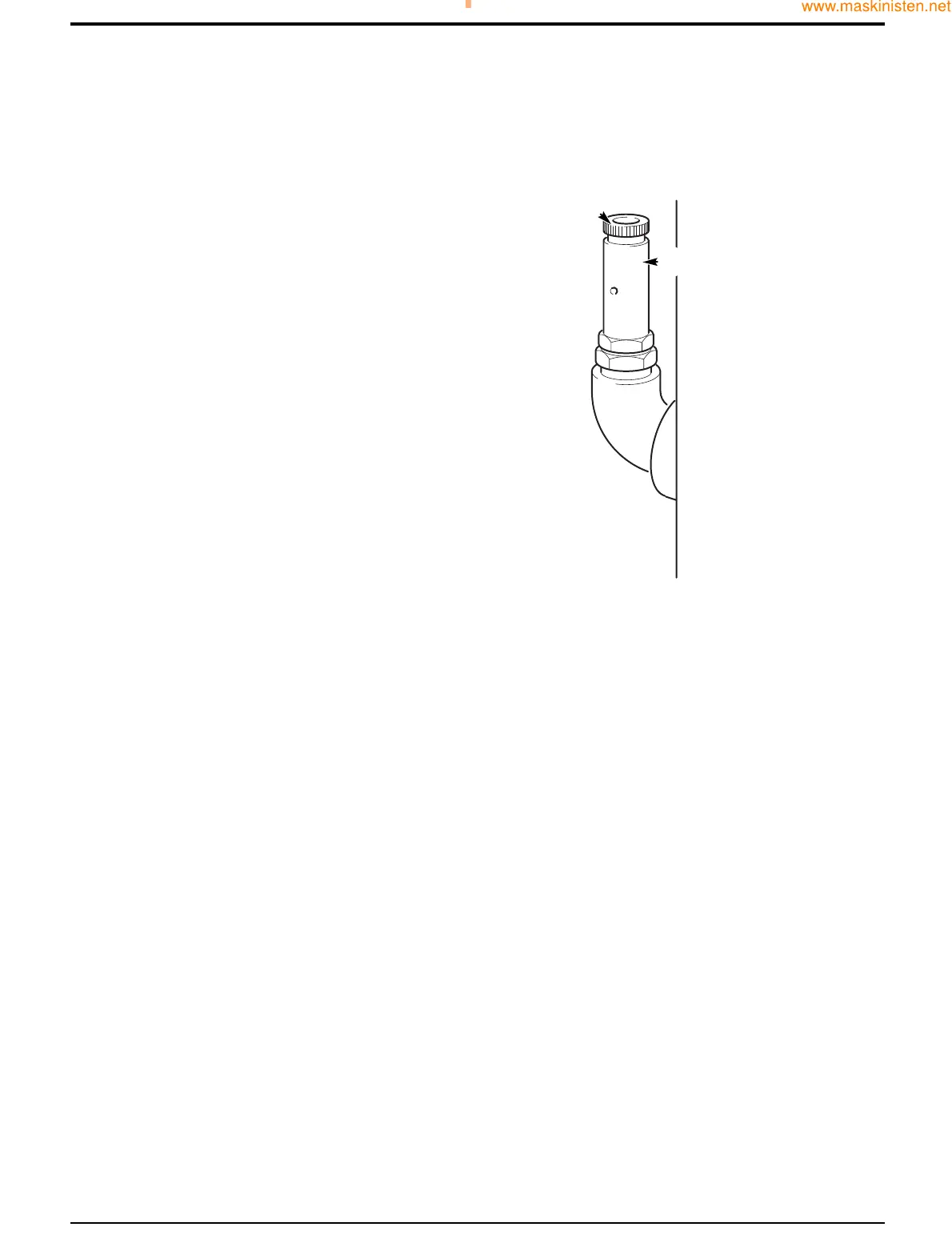

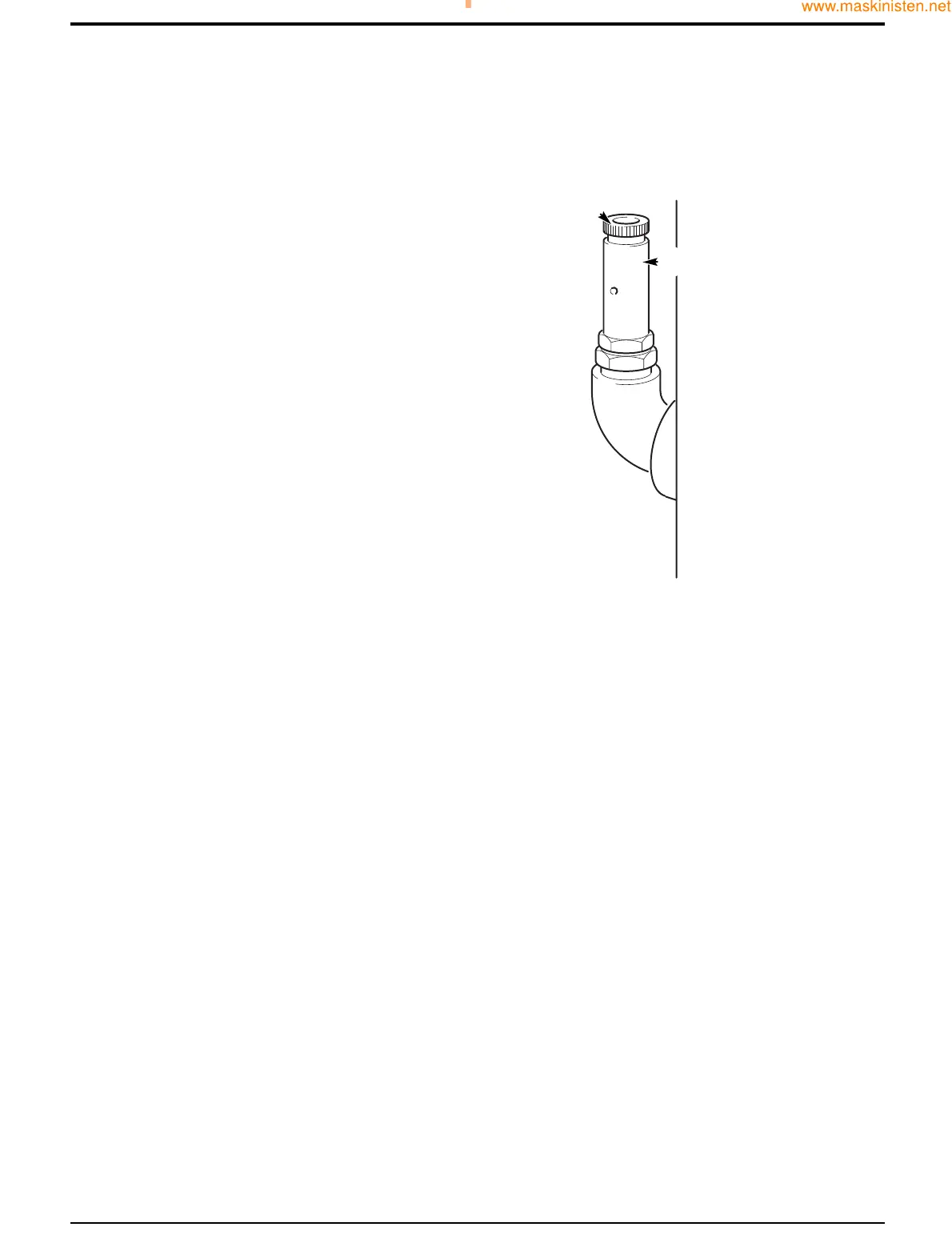

Checking Safety Valve Operation

Check the safety valve A is free to operate by turning its

knurled top cover B anti-clockwise until air is discharged

from the ports in the base of the valve. Screw the cover

down again on completion.

IMPORTANT: The locking wire MUST NOT be broken, the

safety valve is set at the factory, if for any reason the safety

valve does not work, then it must be replaced as a full unit.

The new unit must have the locking wire fitted.

Refer to Pressure Regulator, ‘Checking Safety Valve

Setting’ for a description on how to check the safety valve

setting.

Section A Attachments

9803/7130

Section A

5 - 10

Issue 1

Airmaster Compressor

Loading...

Loading...