20 - 1

Hydraulic Contamination

Hydraulic Fluid Quality

Construction machinery uses a large volume of fluid in the

hydraulic system for power transmission, equipment

lubrication, rust prevention and sealing.

According to a survey conducted by a pump manufacturer,

seventy per cent of the causes of problems in hydraulic

equipment were attributable to inadequate maintenance of

the quality of the hydraulic fluid.

Therefore, it is obvious that control of the quality of the

hydraulic fluid helps prevent hydraulic equipment problems

and greatly improves safety and reliability. Furthermore from

an economic angle it extends the life of the hydraulic fluid if

quality is maintained.

Effects of Contamination

Once inside the system, hydraulic circuit contaminants

greatly effect the performance and life of hydraulic

equipment. For example, contaminants in a hydraulic pump

develop internal wear to cause internal leakage and hence

lower discharges. Wear particles generated will circulate

with the hydraulic fluid to cause further deterioration in the

performance of this and other equipment.

Contaminants also enter principal sliding sections of the

equipment causing temporary malfunction, scuffing, sticking

and leakage and can lead to major problems.

The main contaminants can be classified as follows:-

1 Solid Particles - sand, fibres, metallic particles,

welding scale, sealing materials and wear particles etc.

2 Liquid - usually water and incompatible oils and

greases.

3 Gases - Air, sulphur dioxide etc. which can create

corrosive compounds if dissolved in the fluid.

These contaminants can appear during manufacture,

assembly and operation.

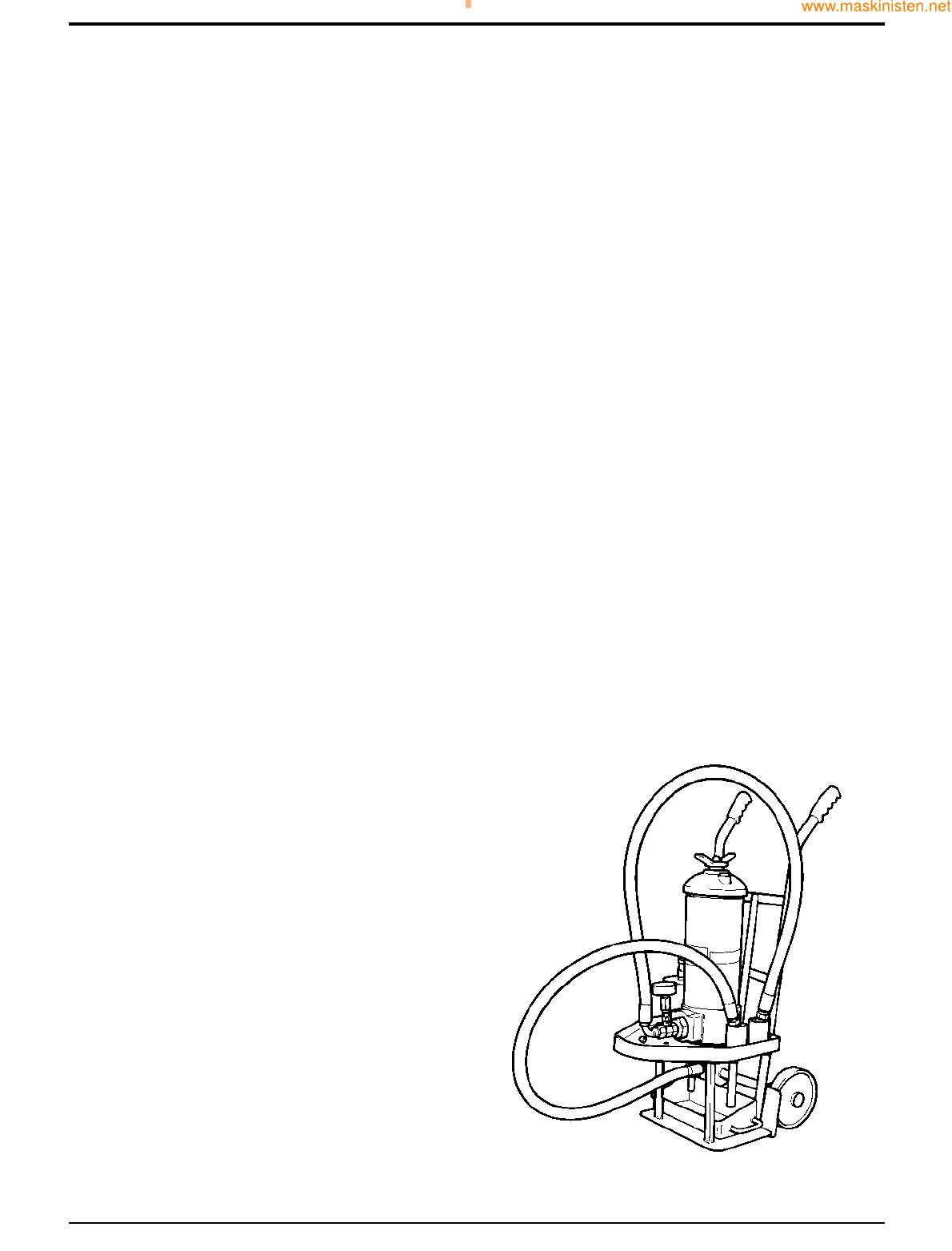

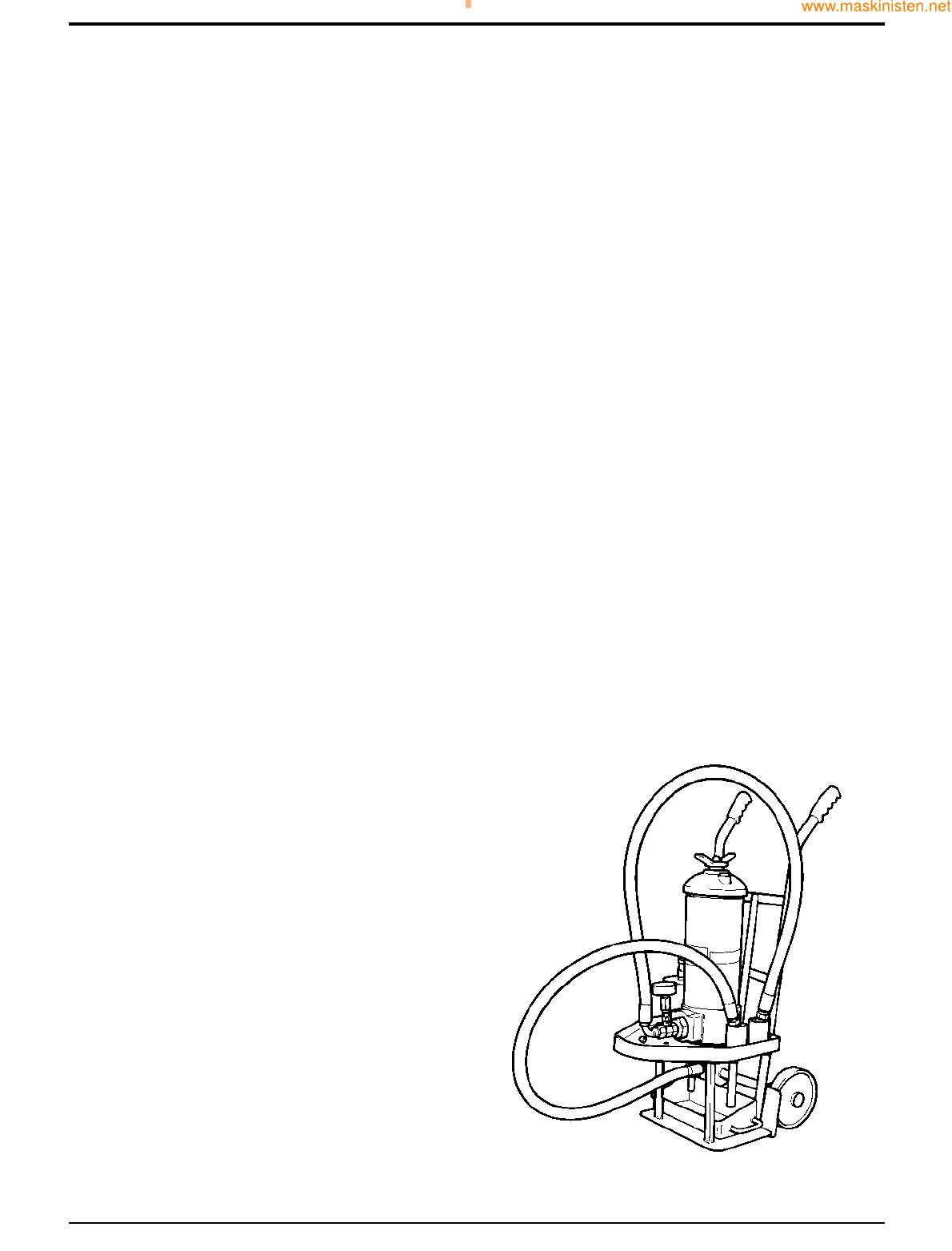

Cleaning Operation

The purpose of cleaning oil is to remove contaminants of all

types and sludge by filtering hydraulic fluid through a

cleaning unit, as illustrated or similar. General Bulletin 011

also refers.

Procedure

Connect the cleaning unit in place of the hydraulic filter and

run the system for sufficient time to pump all the hydraulic

fluid through the unit. Disconnect the cleaning unit and

reconnect the filter. Top up the system with clean hydraulic

fluid as required.

Contaminant Standards

Dirt that damages your system is in many cases too small to

be seen with the eye. The particle size is measured in

microns.

1 micron= 0.001 mm (0.0000394 in)

Listed below are a few typical comparisons:-

Red Blood Cell = 8 microns (0.008 mm, 0.000315 in)

Human Hair = 70 microns (0.07 mm, 0.00275 in)

Grain of Salt = 100 microns (0.1 mm, 0.00394 in)

Smallest particle visible to the naked eye is 40 microns

(0.00157) approximately.

Standards will often be quoted to ISO (International

Standards Organisation) for which literature can be

obtained.

Filters

The filter assembly fitted to all product ranges is designed to

filter all the contamination that is generated through use to

the required level of cleanliness. The filter must be serviced

to the requirements of the machine Service Schedules.

To ensure optimum performance and reliability it is

important that the machines hydraulic system is serviced

periodicaly in accordance with the manufacturers

requirements. For service schedules refer to Section 3

Routine Maintenance -

Section E Hydraulics

9803/7130

Section E

20 - 1

Issue 1

Service Procedures

S168050

Loading...

Loading...