Dismantling and Assembly:

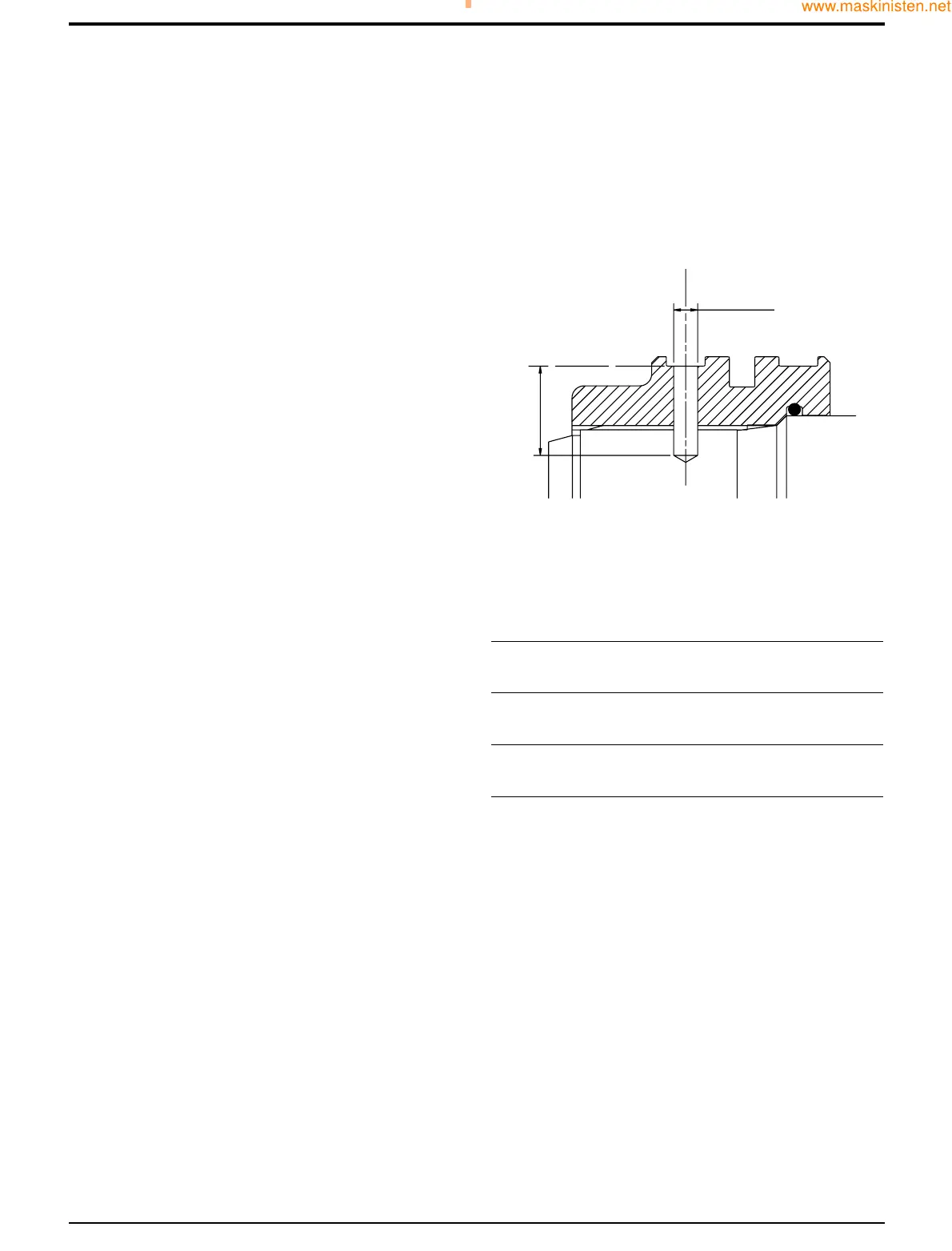

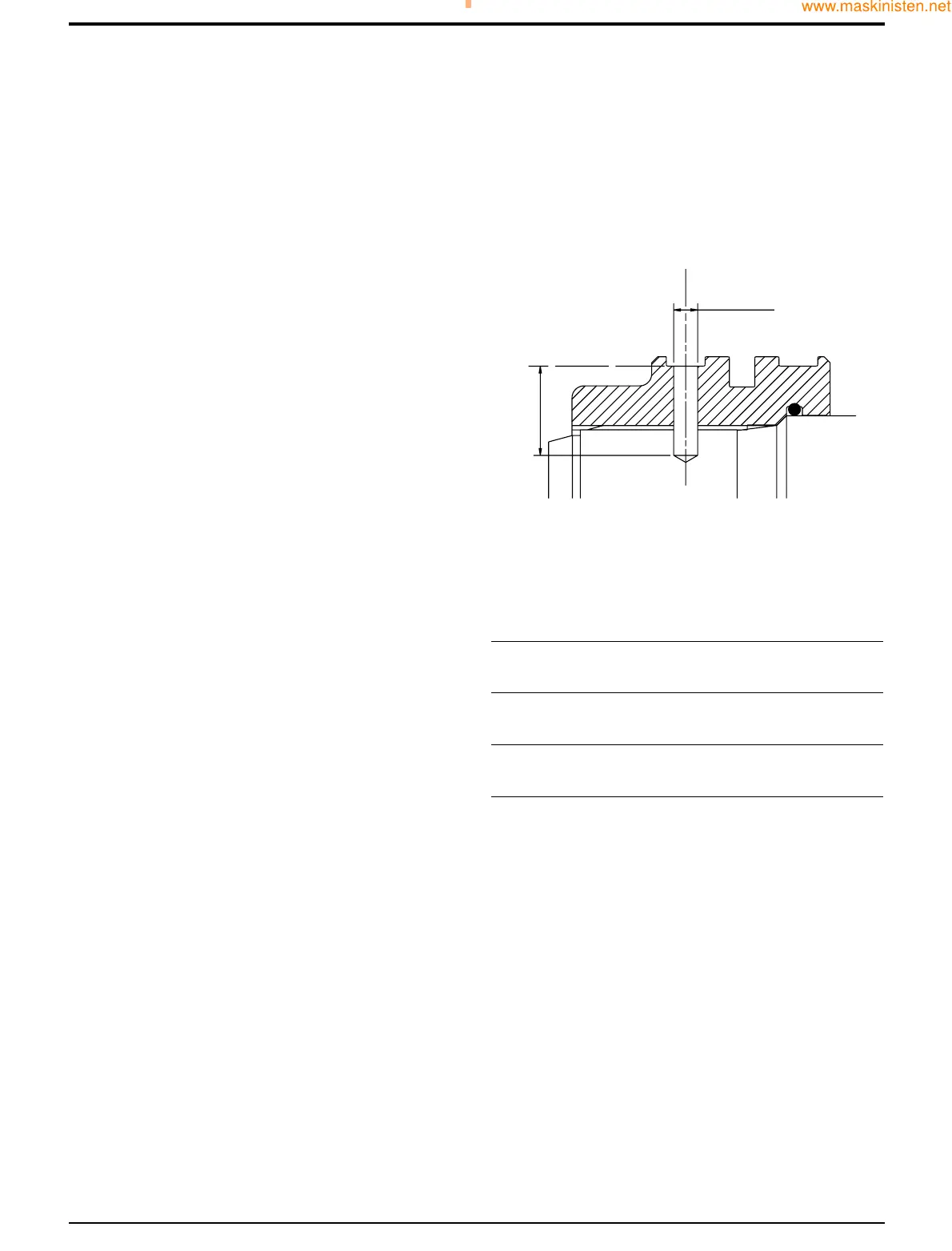

- Typical Ram

When Assembling (continued)

ii Use an undersized diameter drill as a guide and drill

into the piston rod to the required depth (see table),

make sure the drill has centred correctly on the

'centre mark' made at step 5i.

iii Use the correct size diameter drill to suit the dowel

and drill to the required depth (see table).

iv Remove all swarf and contamination, insert the

dowel.

Position cylinder on bench and install rod assembly into

cylinder.

Apply JCB Threadlocker to first three threads of cylinder,

torque tighten the end cap to 678 Nm (500 lbf ft).

Note: If hydraulic oil contacts uncured Threadlocker a

weakening of the bond will result. Allow at least 2 hours cure

time at an ambient temperature of 20

o

C before filling the

ram with oil.

Note: Cold weather operation. When operating in conditions

which are consistently below freezing, it is recommended

that the rams are operated slowly to their full extent before

commencing normal working.

Torque Settings

Item Nm kgf m lbf ft

7 405 41.3 300

1 678 69.2 500

DRILLING DETAILS FOR PISTON HEAD RETENTION

(all dimensions in mm)

Ram Dowel Guide Guide Dowel Dowel

Size Size Drill Ø Drill Drill Ø X Drill

Depth Depth Y

80 x 50 6Ø x 20 4 21 6.02/6.10 22/23

70 x 40

90 x 50 8Ø x 25 5 24 8.02/8.10 27/28

100 x 60

110 x 60 12Ø x 30 8 28 12.02/12.10 32/33

110 x 65

120 x 65 12Ø x 35 8 33 12.02/12.10 37/38

130 x 75

80 - 3

Section E Hydraulics

9803/7130

Section E

80 - 3

Issue 1

Hydraulic Rams

Loading...

Loading...