6

English

Milling cutter

2-sided clamp

Clamp handle

Slide

Slide handle

Fold-away stop

Tracer point

Start switch

Tracer point adjustment control

1

2

3

4

5

6

7

8

9

Head

Neck

Top shoulder

Bottom shoulder

Teeth

Blade

Back

Tip

1

2

3

4

5

6

7

8

The ECCO machine is a robust and precise manual

machine for cutting flat cylinder lock keys, vehicle keys,

cross-shaped keys and special keys.

See Figure 2

Presentation

and general aspects

1

Characteristics

of the machine

2

The main technical information is as follows:

Motor: Single phase 220V, 50Hz, 0.18Kw,1500 rpm, 1.7 Amp.

or Single phase 110V, 60Hz,0.18Kw, 1800 rpm 3.14 Amp.

Milling cutter: Extra quick speed steel Ø63 x 16 x5 mm.

Speed: 1.500 rpm.

Clamps: 2 sided.

Displacement: On self-lubricated bearings.

Effective travel: X axis = 70 mm.

Dimensions:

Width = 470 mm, Depth = 245 mm,

Height = 280 mm.

Weight: 15 Kg.

Technical information

2.3

The ECCO key cutting machine has been designed

taking into account the safety standards currently in

force in the EU.

Although the machine is not difficult to install, it is best

not to try to install, adjust or use it without having first

read this manual.

The machine leaves our factory ready for use and only

requires the carrying out of calibration operations for

the tools that are going to be used.

The machine comes packed in packing of the following

size:

Width = 570 mm, length = 520 mm, height = 410mm

Machine weight plus packing = 18.5 Kg.

When the machine has been unpacked, check carefully

to see if it has suffered any damage during transporta-

tion. If you find any problems, please inform the carrier

immediately and do not do anything with the machine

until the carrier’s agent has carried out an inspection.

General points

1.1

The ECCO key cutting machine has an identification

label, giving the serial number, the name and address of

the manufacturer, the CE mark and the year of manu-

facture. See figure 1

Identification label

1.3

Transport and packing

1.2

Main elements of the machine

2.2

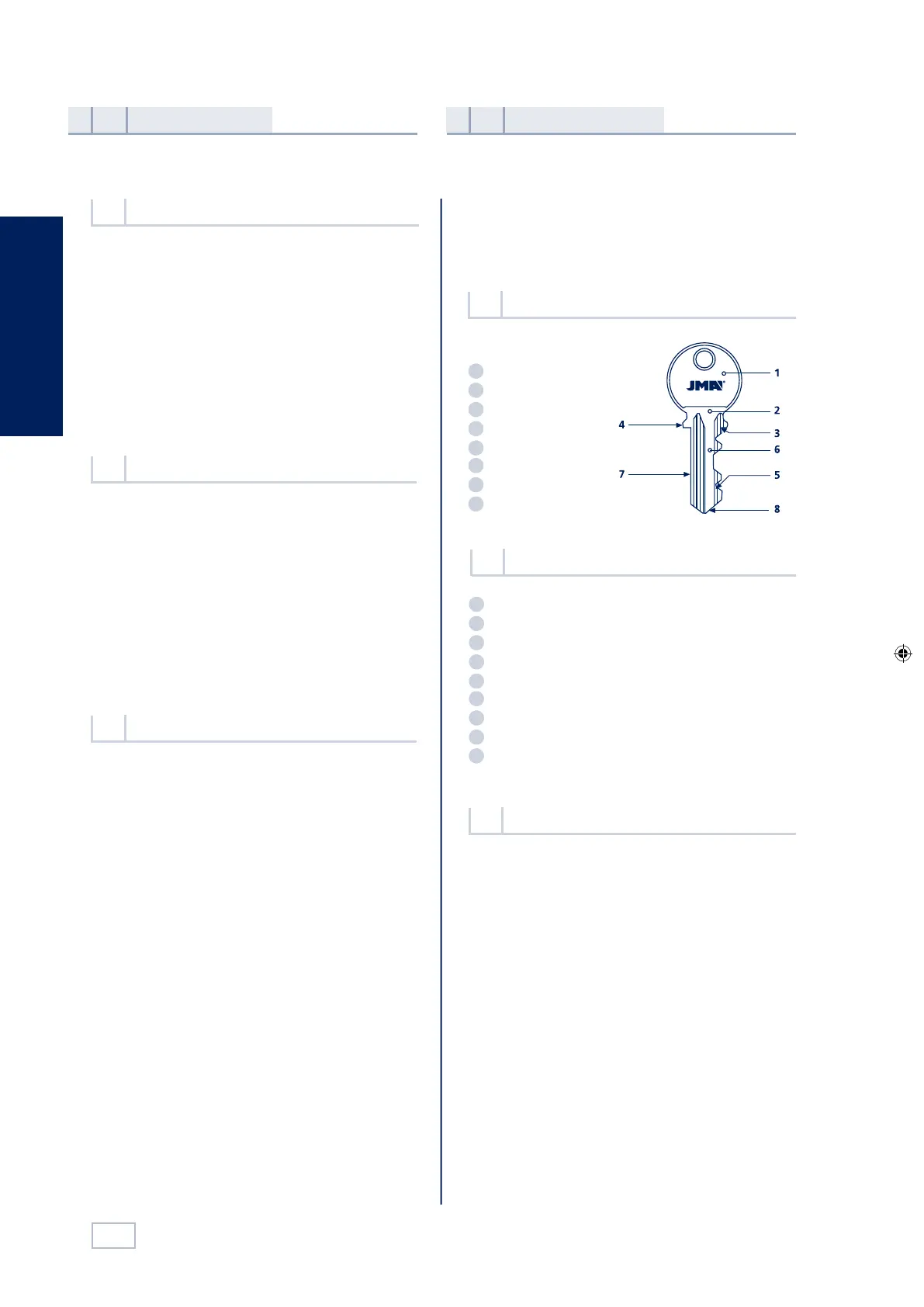

Parts of a key

2.1

6

English

Milling cutter

2-sided clamp

Clamp handle

Slide

Slide handle

Fold-away stop

Tracer point

Start switch

Tracer point adjustment control

1

2

3

4

5

6

7

8

9

Head

Neck

Top shoulder

Bottom shoulder

Teeth

Blade

Back

Tip

1

2

3

4

5

6

7

8

The ECCO machine is a robust and precise manual

machine for cutting flat cylinder lock keys, vehicle keys,

cross-shaped keys and special keys.

See Figure 2

Presentation

and general aspects

1

Characteristics

of the machine

2

The main technical information is as follows:

Motor: Single phase 220V, 50Hz, 0.18Kw,1500 rpm, 1.7 Amp.

or Single phase 110V, 60Hz,0.18Kw, 1800 rpm 3.14 Amp.

Milling cutter: Extra quick speed steel Ø63 x 16 x5 mm.

Speed: 1.500 rpm.

Clamps: 2 sided.

Displacement: On self-lubricated bearings.

Effective travel: X axis = 70 mm.

Dimensions:

Width = 470 mm, Depth = 245 mm,

Height = 280 mm.

Weight: 15 Kg.

Technical information

2.3

The ECCO key cutting machine has been designed

taking into account the safety standards currently in

force in the EU.

Although the machine is not difficult to install, it is best

not to try to install, adjust or use it without having first

read this manual.

The machine leaves our factory ready for use and only

requires the carrying out of calibration operations for

the tools that are going to be used.

The machine comes packed in packing of the following

size:

Width = 570 mm, length = 520 mm, height = 410mm

Machine weight plus packing = 18.5 Kg.

When the machine has been unpacked, check carefully

to see if it has suffered any damage during transporta-

tion. If you find any problems, please inform the carrier

immediately and do not do anything with the machine

until the carrier’s agent has carried out an inspection.

General points

1.1

The ECCO key cutting machine has an identification

label, giving the serial number, the name and address of

the manufacturer, the CE mark and the year of manu-

facture. See figure 1

Identification label

1.3

Transport and packing

1.2

Main elements of the machine

2.2

Parts of a key

2.1

7

English

2.4.2 Electric circuit See Figure 4

The main components of the electric circuit and

the electronic components are as follows:

1

2

3

Socket

Start switch

Motor

How the machine

works

3

Components and functional parts

2.4

Machine adjustement

3.1

4

5

1

2

3

Size 18 spanner.

Keys to adjust the height and depth of the

teeth.

Wedges to adjust the tip of the key.

Recessed wedges to cut cross-shaped keys.

Set of allen keys (2, 2.5, 3).

2.4.1 Accesories See Figure 3

2.4.3 2-sided clamp See Figure 5

The clamp is designed to secure a different family

of keys on each side. The figure shows the possibi-

lities for cutting on each side of the clamp.

1) Cutting the key with support on the back:

• Keys with normal blade

• Keys with narrow blade

2) Cutting by means of clamping the key by the

guide (profile).

3.1.1 Control and adjustment of the side distance

• Place the two adjustment keys (1) in the clamps, so

that the head of the adjustment key rests against

the inner stop of side 1 or 2 of the clamp.

• Then tighten the clamps.

• Move the clamps with the adjustment keys (1)

towards the tracer point (I) and the milling cut-

ter (F), so that the adjustment keys are in the

correct position in respect of the tracer point

and milling cutter. This is done by gently moving

the slide over the tracer point (I) and the milling

cutter (F).

See Figure 6.

• If the grooves of the adjustment key do not

coincide properly with the tracer point and the

milling cutter, proceed as follows:

• By gently loosening the shaft screws (T), you will

be able to move the milling cutter to the right

or left. You have to move the milling cutter to a

position in which it coincides with the groove of

the corresponding adjustment key. To carry out

this operation, you have to remove the motor

guard first.

• The distance is now perfectly adjusted, with the

tracer point and milling cutter coinciding with

the respective recesses of the adjustment keys.

Now tighten the shaft screws (T).

3.1.2 Control and adjustment of the cutting depth

• Place the two adjustment keys (1) in the clamps, so

that the head of the adjustment key rests against

the inner stop of side 1 or 2 of the clamp.

• Move the clamps with the adjustment keys (1)

towards the tracer point (I) and the milling cutter

(F), so that the adjustment keys rest on the tracer

point and the milling cutter.

• Turn the milling cutter by hand. If it gently rubs the

adjustment keys, the machine is properly adjusted.

• If the milling cutter turns freely, without rubbing,

this indicates that it is to far back in respect of the

tracer point and is not cutting deeply enough. On

the other hand, if the milling cutter becomes jam-

med up against the adjustment key, this indicates

that it is too far forward in respect of the tracer

point and is cutting too deeply.

• If either of these situations should occur, proceed as

follows:

- Undo the screw (L) securing the tracer point (I)

and turn the micrometric screw (H) See Figure 7.

- Move the tracer point forwards or backwards

until the milling cutter turns freely and rubs

gently against the adjustment key. Then tig-

hten the tracer point screw (L).The machine is

now in perfect working order.

man_ecco.indd 6 03/09/14 11:35

7

English

2.4.2 Electric circuit See Figure 4

The main components of the electric circuit and

the electronic components are as follows:

1

2

3

4

Socket

Start switch

Motor

Connection plate

How the machine

works

3

Components and functional parts

2.4

Machine adjustement

3.1

4

5

1

2

3

Size 18 spanner.

Keys to adjust the height and depth of the

teeth.

Wedges to adjust the tip of the key.

Recessed wedges to cut cross-shaped keys.

Set of allen keys (2, 2.5, 3).

2.4.1 Accesories See Figure 3

2.4.3 2-sided clamp See Figure 5

The clamp is designed to secure a dierent family

of keys on each side. The gure shows the possibi-

lities for cutting on each side of the clamp.

1) Cutting the key with support on the back:

• Keys with normal blade

• Keys with narrow blade

2) Cutting by means of clamping the key by the

guide (prole).

3.1.1 Control and adjustment of the side distance

• Place the two adjustment keys (1) in the clamps, so

that the head of the adjustment key rests against

the inner stop of side 1 or 2 of the clamp.

• Then tighten the clamps.

• Move the clamps with the adjustment keys (1)

towards the tracer point (I) and the milling cut-

ter (F), so that the adjustment keys are in the

correct position in

respect of the tracer point

and milling cutter. This is done by gently moving

the slide over the tracer point (I) and the milling

cutter (F).

See Figure 6.

• If the grooves of the adjustment key do not

coincide properly with the tracer point and the

milling cutter, proceed as follows:

• By gently loosening the shaft screws (T), you will

be able to move the milling cutter to the right

or left. You have to move the milling cutter to a

position in which it coincides with the groove of

the corresponding adjustment key. To carry out

this operation, you have to remove the motor

guard rst.

• The distance is now perfectly adjusted, with the

tracer point and milling cutter coinciding with

the respective recesses of the adjustment keys.

Now tighten the shaft screws (T).

3.1.2 Control and adjustment of the cutting depth

• Place the two adjustment keys (1) in the clamps, so

that the head of the adjustment key rests against

the inner stop of side 1 or 2 of the clamp.

• Move

the clamps with the adjustment keys (1)

towards the tracer point (I) and the milling cutter

(F), so that the adjustment keys rest on the tracer

point and the milling cutter.

• Turn the milling cutter by hand. If it gently rubs the

adjustment keys, the machine is properly adjusted.

• If the milling cutter turns freely, without rubbing,

this indicates that it is to far back in respect of the

tracer point and is not cutting deeply enough. On

the other hand, if the milling cutter becomes jam-

med up against the adjustment key, this indicates

that it is too far forwa

rd in respect of the tracer

point and is cutting too deeply.

• If either of these situations should occur, proceed as

follows:

- Undo the screw (L) securing the tracer point (I)

and turn the micrometric screw (H) See Figure 7.

- Move the tracer point forwards or backwards

until the milling cutter turns freely and rubs

gently against the adjustment key. Then tig-

hten the tracer point screw (L).The machine is

now in perfect working order.

6

1.20 mm rods

1.70 mm rods

7

man_ecco.indd 7 03/09/14 10:05

Loading...

Loading...