8

English

When carrying out maintenance operations, the follo-

wing requirements must be met:

Maintenance and

safety

4

• For segurity reasons, the manipulation of the keys and

machine have to be done with the motor turned off, the

red switch has to be at OFF position, the switch light is

off. The machine has to be start only when we are going

to cut the blank key.

• Insert the original key into the left-hand clamp, keeping

it a distance of 2 to 3 mm from the edge of the clamp.

See Figure 8.

• Tighten up the clamp, keeping the back of the key pro-

perly pressed against the base of the clamp.

• Insert the key blank to be cut into the right-hand clamp

and, before tightening up the clamp, raise the gauge (C)

and align the two keys. Ensure that the two pointers of

the gauge are resting firmly up against the top shoul-

ders of both keys. Finally, tighten up the clamps.

• Both the original key and the key blank to be cut should

be inserted in the left-hand side of the respective clamps.

• Withdraw the gauge (C). Start the machine and hold

the slide by means of the handle (M). Move the keys

towards the tracer point (I) and the milling cutter (F).

• Remember that you have to work from left to right.

Rest the original key against the tracer point and start

to work, moving the slide from right to left, using the

handle (M) and ensuring that the original key presses

gently against the tracer point.

• Once the key has been cut, return the slide to its initial

position, and don’t forget to turn OFF the machine to

stop the milling cutter. Then remove the keys by undo-

ing the clamps.

Key cutting operation

3.2

Do not try and start or handle the machine until all

safety matters, installation instructions, operator gui-

des and maintenance procedures have been fulfilled

and understood.

Always switch off the power supply before carrying

out any cleaning or maintenance operation.

Always keep the machine as well as its surroundings

clean.

Work with dry hands.

Use safety glasses, even if the machine is fitted with

guards.

Ensure that the machine is earthed.

Safety recommendations

4.2

Changing the milling cutter

4.1

3.2.1 Duplication of narrow bit key.

Use of rods 1.2 and 1.7

The rods are inserted between the bottom of the

clamp and the back of the key when the key to be

duplicated has a narrow bit. The rods prevent contact

with the clamp itself by making the key protrude

further. (See Figure 9).

3.2.2 Cutting keys without shoulders

Insert the two wedges (2) (see Figure.10) into the

vertical slots (R) of each clamp, depending on the

length of the key to be cut.

Rest the tips of the keys against the wedges (2).

The keys are now adjusted. Then tighten up the

clamps. Before starting to cut the key, it is advisa-

ble to remove the wedges.

3.2.3 Cutting cross-shaped keys.

Side 1 of the clamp

This type of key must be inserted into the clamps from

left to right. Place the wedges (5) (See Figure 11) with

the opening or recess facing upwards, in one slot or

the other (R), depending on the length of the key to

be cut.

The teeth of the key can be cut in three operations,

by turning and locking the shoulder of the key against

the wedge (5) each time.

Never carry out any maintenance operation with the

machine switched on.

Unplug the machine.

The indications in this manual must be strictly adhe-

red to.

Use original spare parts.

3

1

2

4

3

1

2

6

5

4

Undo the two milling cutter guard screws and remove

the guard.

To change the milling cutter: With the help of the two

size 18 spanners, lock the milling cutter shaft and undo

the nut (K) – left-hand thread – securing the milling cut-

ter (F). Then replace the milling cutter and finally put the

milling cutter guard back into place. See Figure.12

8

English

When carrying out maintenance operations, the follo-

wing requirements must be met:

Maintenance and

safety

4

• For segurity reasons, the manipulation of the keys and

machine have to be done with the motor turned off, the

red switch has to be at OFF position, the switch light is

off. The machine has to be start only when we are going

to cut the blank key.

• Insert the original key into the left-hand clamp, keeping

it a distance of 2 to 3 mm from the edge of the clamp.

See Figure 8.

• Tighten up the clamp, keeping the back of the key pro-

perly pressed against the base of the clamp.

• Insert the key blank to be cut into the right-hand clamp

and, before tightening up the clamp, raise the gauge (C)

and align the two keys. Ensure that the two pointers of

the gauge are resting firmly up against the top shoul-

ders of both keys. Finally, tighten up the clamps.

• Both the original key and the key blank to be cut should

be inserted in the left-hand side of the respective clamps.

• Withdraw the gauge (C). Start the machine and hold

the slide by means of the handle (M). Move the keys

towards the tracer point (I) and the milling cutter (F).

• Remember that you have to work from left to right.

Rest the original key against the tracer point and start

to work, moving the slide from right to left, using the

handle (M) and ensuring that the original key presses

gently against the tracer point.

• Once the key has been cut, return the slide to its initial

position, and don’t forget to turn OFF the machine to

stop the milling cutter. Then remove the keys by undo-

ing the clamps.

Key cutting operation

3.2

Do not try and start or handle the machine until all

safety matters, installation instructions, operator gui-

des and maintenance procedures have been fulfilled

and understood.

Always switch off the power supply before carrying

out any cleaning or maintenance operation.

Always keep the machine as well as its surroundings

clean.

Work with dry hands.

Use safety glasses, even if the machine is fitted with

guards.

Ensure that the machine is earthed.

Safety recommendations

4.2

Changing the milling cutter

4.1

3.2.1 Duplication of narrow bit key.

Use of rods 1.2 and 1.7

The rods are inserted between the bottom of the

clamp and the back of the key when the key to be

duplicated has a narrow bit. The rods prevent contact

with the clamp itself by making the key protrude

further. (See Figure 9).

3.2.2 Cutting keys without shoulders

Insert the two wedges (2) (see Figure.10) into the

vertical slots (R) of each clamp, depending on the

length of the key to be cut.

Rest the tips of the keys against the wedges (2).

The keys are now adjusted. Then tighten up the

clamps. Before starting to cut the key, it is advisa-

ble to remove the wedges.

3.2.3 Cutting cross-shaped keys.

Side 1 of the clamp

This type of key must be inserted into the clamps from

left to right. Place the wedges (5) (See Figure 11) with

the opening or recess facing upwards, in one slot or

the other (R), depending on the length of the key to

be cut.

The teeth of the key can be cut in three operations,

by turning and locking the shoulder of the key against

the wedge (5) each time.

Never carry out any maintenance operation with the

machine switched on.

Unplug the machine.

The indications in this manual must be strictly adhe-

red to.

Use original spare parts.

3

1

2

4

3

1

2

6

5

4

Undo the two milling cutter guard screws and remove

the guard.

To change the milling cutter: With the help of the two

size 18 spanners, lock the milling cutter shaft and undo

the nut (K) – left-hand thread – securing the milling cut-

ter (F). Then replace the milling cutter and finally put the

milling cutter guard back into place. See Figure.12

9

Deutsch

Fräser

2-seite Spannbacke

Handgriff der Spannbacke

Schlitten

Handgriff des Schlittens

Klappbarer Anschlag

Fühler

Schalter für Inbetriebnahme

Einstellvorrichtung für den Fühler

1

2

3

4

5

6

7

8

9

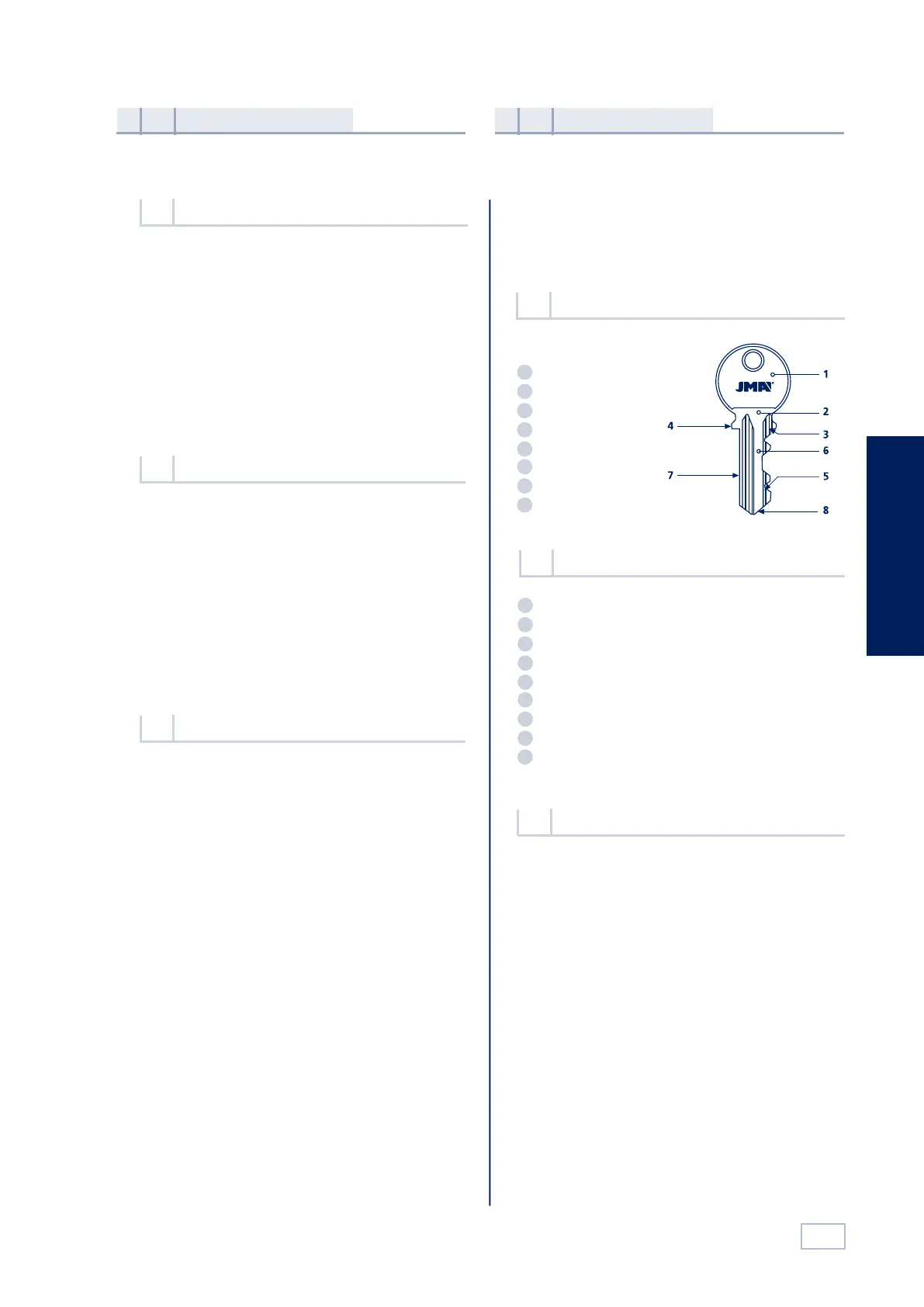

Schlüsselkopf

Schlüsselhals

Oberer Anschlag

Unterer Anschlag

Zahnung

Schlüsselbart

Schlüsselrücken

Schlüsselspitze

1

2

3

4

5

6

7

8

Bei der Maschine ECCO handelt es sich um eine äußerst

robust ausgeführte und präzise arbeitende manuelle

Kopiermaschine für Flachschlüssel für Zylinderschlösser,

Fahrzeugschlüssel, kreuzförmige Schlüssel und

Sonderschlüssel.

Siehe Abbildung 2

Vorstellung und

grundlegende begriffe

1

Eigenschaften

der maschine

2

Die Schlüsselkopiermaschine ECCO ist unter

Berücksichtigung der in der EU geltenden

Sicherheitsnormen entworfen worden.

Auch wenn die Installation der Maschine keinerlei

Schwierigkeiten bereitet, sollte sie nicht installiert,

eingestellt oder bedient werden, ohne zuvor das vorlie-

gende Handbuch gründlich gelesen zu haben.

Die Maschine ist werkseitig für den Gebrauch eingeste-

llt, so daß lediglich die Eichvorgänge für die zu verwen-

denden Werkzeuge vorzunehmen sind.

Die Maschine wird in einer Verpackung mit folgenden

Abmessungen ausgeliefert:

Breite = 570 mm, Länge = 520 mm, Höhe = 410mm

Maschinengewicht zusätzlich Verpackung = 18,5 kg.

Beim Auspacken der Maschine ist diese sorgfältig auf

eventuelle Transportschäden zu untersuchen. Sollten

Sie Beschädigungen feststellen, so wenden Sie sich bitte

umgehend an den Spediteur und belassen die Maschine

so wie sie ist, bis der zuständige Vertreter der Spedition

die entsprechende Überprüfung vorgenommen hat.

Allgemeines

1.1

An der Schlüsselkopiermaschine ECCO befindet sich

ein Typenschild, auf dem die Seriennummer, sowie

der Name und die Anschrift des Herstellers, die CE-

Kennzeichnung und das Baujahr angegeben werden.

Siehe Abbildung 1.

Typenschild

1.3

Die wichtigsten technischen Daten sind folgende:

Motor: Einphasig 220V, 50Hz, 0,18 kW, 1500 UpM, 1,7 Amp.

oder einphasig 110V, 60Hz, 0,18Kw, 1800 UpM, 3,14 Amp.

Fräser: Schnellarbeitsstahl Ø63 x 16 x5 mm.

Geschwindigkeit: 1.500 UpM.

Spannbacken: 2-seite.

Verfahrbewegung: Auf selbstschmierenden Lagern.

Verfahrweg: X-Achse = 70 mm.

Abmessungen: Breite = 470 mm, Tiefe = 245 mm,

Höhe = 280 mm.

Gewicht: 15 Kg.

Technische daten

2.3

Transport und verpackung

1.2

Hauptbestandteile der maschine

2.2

Nomenklatur des schlüssels

2.1

man_ecco.indd 8 03/09/14 11:35

8

English

When carrying out maintenance operations, the follo-

wing requirements must be met:

Maintenance and

safety

4

• For segurity reasons, the manipulation of the keys and

machine have to be done with the motor turned off, the

red switch has to be at OFF position, the switch light is

off. The machine has to be start only when we are going

to cut the blank key.

• Insert the original key into the left-hand clamp, keeping

it a distance of 2 to 3 mm from the edge of the clamp.

See Figure 8.

• Tighten up the clamp, keeping the back of the key pro-

perly pressed against the base of the clamp.

• Insert the key blank to be cut into the right-hand clamp

and, before tightening up the clamp, raise the gauge (C)

and align the two keys. Ensure that the two pointers of

the gauge are resting firmly up against the top shoul-

ders of both keys. Finally, tighten up the clamps.

• Both the original key and the key blank to be cut should

be inserted in the left-hand side of the respective clamps.

• Withdraw the gauge (C). Start the machine and hold

the slide by means of the handle (M). Move the keys

towards the tracer point (I) and the milling cutter (F).

• Remember that you have to work from left to right.

Rest the original key against the tracer point and start

to work, moving the slide from right to left, using the

handle (M) and ensuring that the original key presses

gently against the tracer point.

• Once the key has been cut, return the slide to its initial

position, and don’t forget to turn OFF the machine to

stop the milling cutter. Then remove the keys by undo-

ing the clamps.

Key cutting operation

3.2

Do not try and start or handle the machine until all

safety matters, installation instructions, operator gui-

des and maintenance procedures have been fulfilled

and understood.

Always switch off the power supply before carrying

out any cleaning or maintenance operation.

Always keep the machine as well as its surroundings

clean.

Work with dry hands.

Use safety glasses, even if the machine is fitted with

guards.

Ensure that the machine is earthed.

Safety recommendations

4.2

Changing the milling cutter

4.1

3.2.1 Duplication of narrow bit key.

Use of rods 1.2 and 1.7

The rods are inserted between the bottom of the

clamp and the back of the key when the key to be

duplicated has a narrow bit. The rods prevent contact

with the clamp itself by making the key protrude

further. (See Figure 9).

3.2.2 Cutting keys without shoulders

Insert the two wedges (2) (see Figure.10) into the

vertical slots (R) of each clamp, depending on the

length of the key to be cut.

Rest the tips of the keys against the wedges (2).

The keys are now adjusted. Then tighten up the

clamps. Before starting to cut the key, it is advisa-

ble to remove the wedges.

3.2.3 Cutting cross-shaped keys.

Side 1 of the clamp

This type of key must be inserted into the clamps from

left to right. Place the wedges (5) (See Figure 11) with

the opening or recess facing upwards, in one slot or

the other (R), depending on the length of the key to

be cut.

The teeth of the key can be cut in three operations,

by turning and locking the shoulder of the key against

the wedge (5) each time.

Never carry out any maintenance operation with the

machine switched on.

Unplug the machine.

The indications in this manual must be strictly adhe-

red to.

Use original spare parts.

3

1

2

4

3

1

2

6

5

4

Undo the two milling cutter guard screws and remove

the guard.

To change the milling cutter: With the help of the two

size 18 spanners, lock the milling cutter shaft and undo

the nut (K) – left-hand thread – securing the milling cut-

ter (F). Then replace the milling cutter and finally put the

milling cutter guard back into place. See Figure.12

8

English

When carrying out maintenance operations, the follo-

wing requirements must be met:

Maintenance and

safety

4

• For segurity reasons, the manipulation of the keys and

machine have to be done with the motor turned off, the

red switch has to be at OFF position, the switch light is

off. The machine has to be start only when we are going

to cut the blank key.

• Insert the original key into the left-hand clamp, keeping

it a distance of 2 to 3 mm from the edge of the clamp.

See Figure 8.

• Tighten up the clamp, keeping the back of the key pro-

perly pressed against the base of the clamp.

• Insert the key blank to be cut into the right-hand clamp

and, before tightening up the clamp, raise the gauge (C)

and align the two keys. Ensure that the two pointers of

the gauge are resting firmly up against the top shoul-

ders of both keys. Finally, tighten up the clamps.

• Both the original key and the key blank to be cut should

be inserted in the left-hand side of the respective clamps.

• Withdraw the gauge (C). Start the machine and hold

the slide by means of the handle (M). Move the keys

towards the tracer point (I) and the milling cutter (F).

• Remember that you have to work from left to right.

Rest the original key against the tracer point and start

to work, moving the slide from right to left, using the

handle (M) and ensuring that the original key presses

gently against the tracer point.

• Once the key has been cut, return the slide to its initial

position, and don’t forget to turn OFF the machine to

stop the milling cutter. Then remove the keys by undo-

ing the clamps.

Key cutting operation

3.2

Do not try and start or handle the machine until all

safety matters, installation instructions, operator gui-

des and maintenance procedures have been fulfilled

and understood.

Always switch off the power supply before carrying

out any cleaning or maintenance operation.

Always keep the machine as well as its surroundings

clean.

Work with dry hands.

Use safety glasses, even if the machine is fitted with

guards.

Ensure that the machine is earthed.

Safety recommendations

4.2

Changing the milling cutter

4.1

3.2.1 Duplication of narrow bit key.

Use of rods 1.2 and 1.7

The rods are inserted between the bottom of the

clamp and the back of the key when the key to be

duplicated has a narrow bit. The rods prevent contact

with the clamp itself by making the key protrude

further. (See Figure 9).

3.2.2 Cutting keys without shoulders

Insert the two wedges (2) (see Figure.10) into the

vertical slots (R) of each clamp, depending on the

length of the key to be cut.

Rest the tips of the keys against the wedges (2).

The keys are now adjusted. Then tighten up the

clamps. Before starting to cut the key, it is advisa-

ble to remove the wedges.

3.2.3 Cutting cross-shaped keys.

Side 1 of the clamp

This type of key must be inserted into the clamps from

left to right. Place the wedges (5) (See Figure 11) with

the opening or recess facing upwards, in one slot or

the other (R), depending on the length of the key to

be cut.

The teeth of the key can be cut in three operations,

by turning and locking the shoulder of the key against

the wedge (5) each time.

Never carry out any maintenance operation with the

machine switched on.

Unplug the machine.

The indications in this manual must be strictly adhe-

red to.

Use original spare parts.

3

1

2

4

3

1

2

6

5

4

Undo the two milling cutter guard screws and remove

the guard.

To change the milling cutter: With the help of the two

size 18 spanners, lock the milling cutter shaft and undo

the nut (K) – left-hand thread – securing the milling cut-

ter (F). Then replace the milling cutter and finally put the

milling cutter guard back into place. See Figure.12

9

Deutsch

Fräser

2-seite Spannbacke

Handgriff der Spannbacke

Schlitten

Handgriff des Schlittens

Klappbarer Anschlag

Fühler

Schalter für Inbetriebnahme

Einstellvorrichtung für den Fühler

1

2

3

4

5

6

7

8

9

Schlüsselkopf

Schlüsselhals

Oberer Anschlag

Unterer Anschlag

Zahnung

Schlüsselbart

Schlüsselrücken

Schlüsselspitze

1

2

3

4

5

6

7

8

Bei der Maschine ECCO handelt es sich um eine äußerst

robust ausgeführte und präzise arbeitende manuelle

Kopiermaschine für Flachschlüssel für Zylinderschlösser,

Fahrzeugschlüssel, kreuzförmige Schlüssel und

Sonderschlüssel.

Siehe Abbildung 2

Vorstellung und

grundlegende begriffe

1

Eigenschaften

der maschine

2

Die Schlüsselkopiermaschine ECCO ist unter

Berücksichtigung der in der EU geltenden

Sicherheitsnormen entworfen worden.

Auch wenn die Installation der Maschine keinerlei

Schwierigkeiten bereitet, sollte sie nicht installiert,

eingestellt oder bedient werden, ohne zuvor das vorlie-

gende Handbuch gründlich gelesen zu haben.

Die Maschine ist werkseitig für den Gebrauch eingeste-

llt, so daß lediglich die Eichvorgänge für die zu verwen-

denden Werkzeuge vorzunehmen sind.

Die Maschine wird in einer Verpackung mit folgenden

Abmessungen ausgeliefert:

Breite = 570 mm, Länge = 520 mm, Höhe = 410mm

Maschinengewicht zusätzlich Verpackung = 18,5 kg.

Beim Auspacken der Maschine ist diese sorgfältig auf

eventuelle Transportschäden zu untersuchen. Sollten

Sie Beschädigungen feststellen, so wenden Sie sich bitte

umgehend an den Spediteur und belassen die Maschine

so wie sie ist, bis der zuständige Vertreter der Spedition

die entsprechende Überprüfung vorgenommen hat.

Allgemeines

1.1

An der Schlüsselkopiermaschine ECCO befindet sich

ein Typenschild, auf dem die Seriennummer, sowie

der Name und die Anschrift des Herstellers, die CE-

Kennzeichnung und das Baujahr angegeben werden.

Siehe Abbildung 1.

Typenschild

1.3

Die wichtigsten technischen Daten sind folgende:

Motor: Einphasig 220V, 50Hz, 0,18 kW, 1500 UpM, 1,7 Amp.

oder einphasig 110V, 60Hz, 0,18Kw, 1800 UpM, 3,14 Amp.

Fräser: Schnellarbeitsstahl Ø63 x 16 x5 mm.

Geschwindigkeit: 1.500 UpM.

Spannbacken: 2-seite.

Verfahrbewegung: Auf selbstschmierenden Lagern.

Verfahrweg: X-Achse = 70 mm.

Abmessungen: Breite = 470 mm, Tiefe = 245 mm,

Höhe = 280 mm.

Gewicht: 15 Kg.

Technische daten

2.3

Transport und verpackung

1.2

Hauptbestandteile der maschine

2.2

Nomenklatur des schlüssels

2.1

man_ecco.indd 9 03/09/14 11:35

Loading...

Loading...