– 73 –

In regard to adjustments of the bobbin winder amount and winder

imbalance, refer to the relevant instruction manual.

In this manual, descriptions are provided in regard to problems of winder

shaft revolution errors.

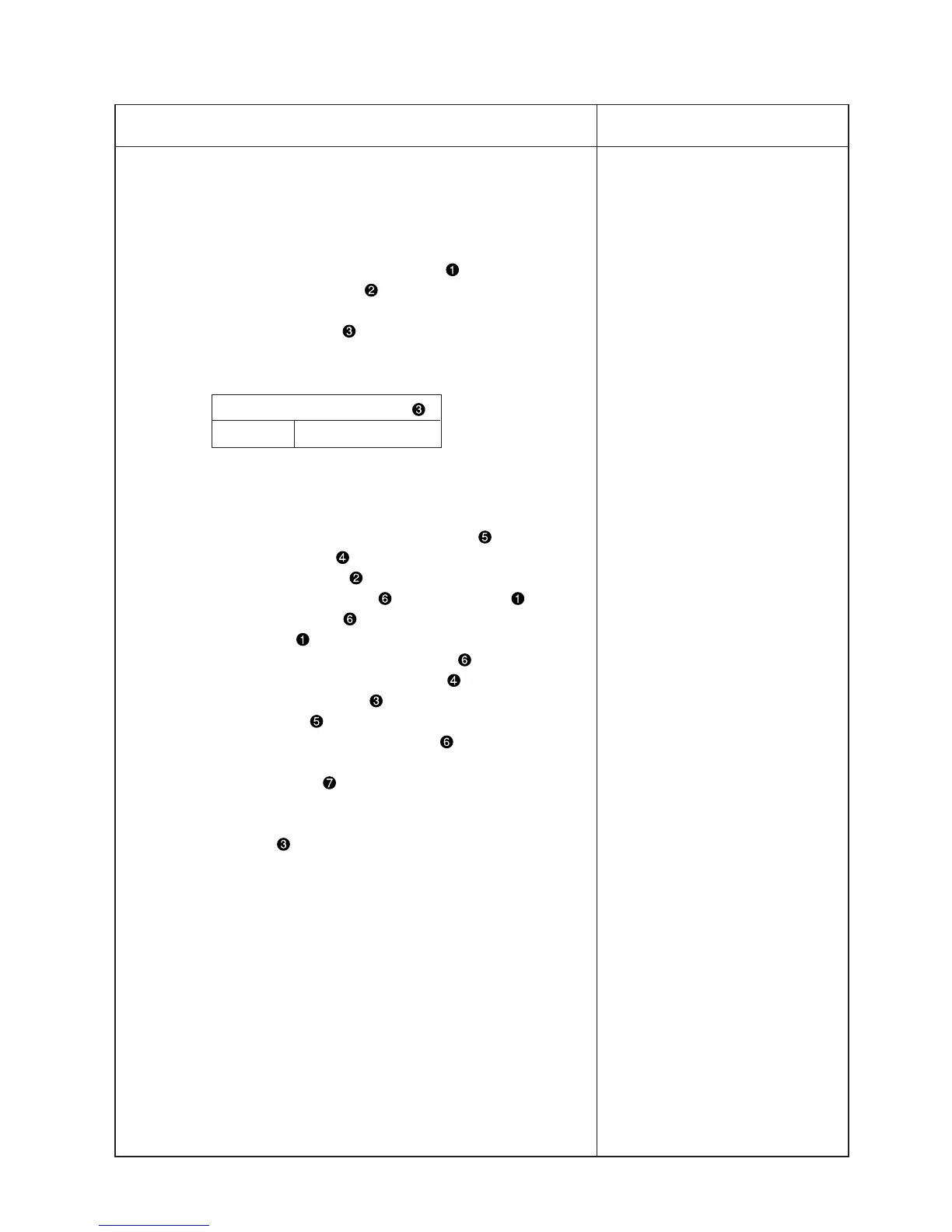

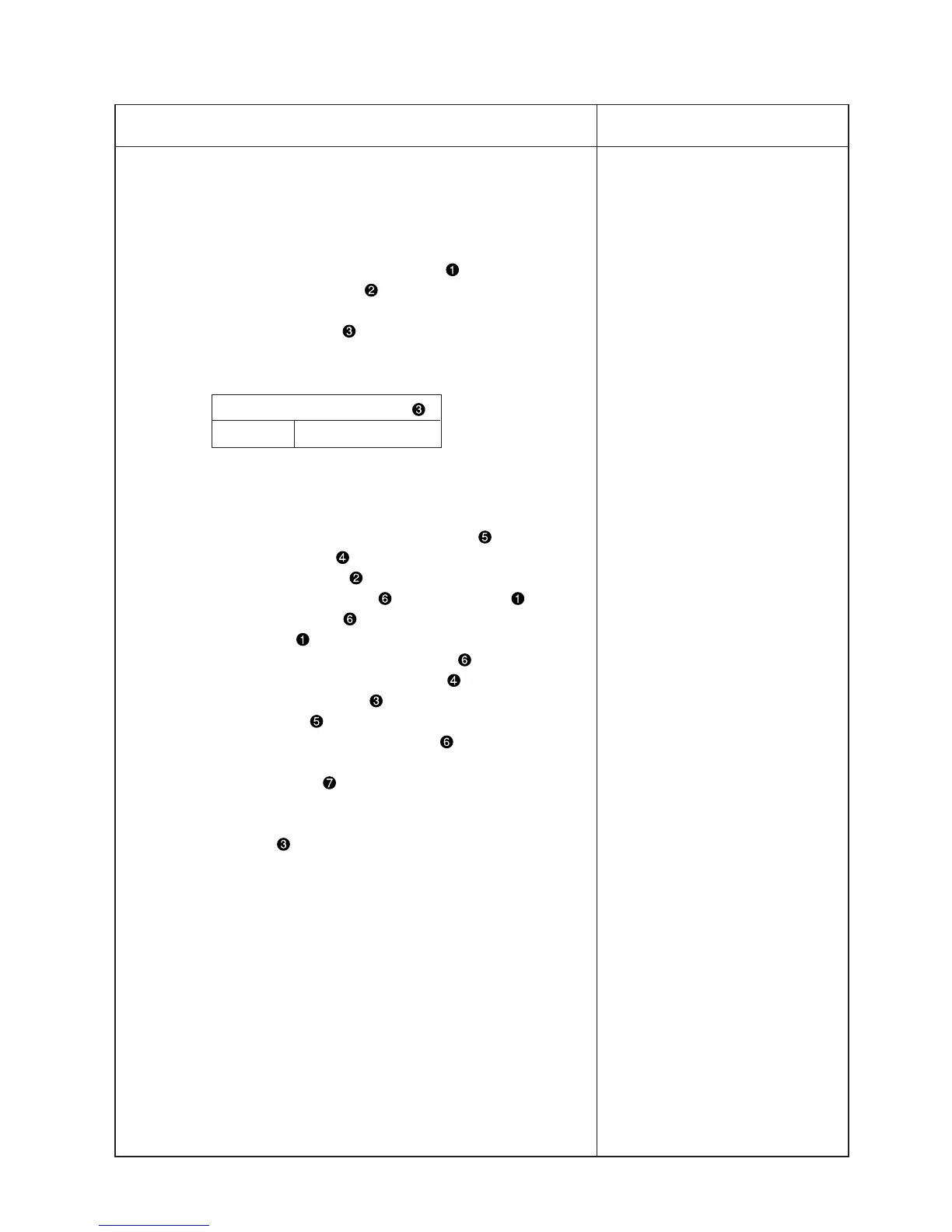

1. Replacement of the bobbin friction wheel

(1) Remove three bobbin winder unit setscrews .

(2) Take out the bobbin winder unit .

(3) Confirm if there is extreme wearing out in the rubber section of the

bobbin winder friction wheel .

If the amount of wearing out seems to be too much, replace the

worn-out section with a new one.

2. Adjustment of the bobbin winder driver wheel position

(1) Remove the window plate (including the AK unit) from the rear side

of the arm.

(2) Loosen the bobbin winder driver wheel setscrews (2 pcs.) of the

bobbin winder driver wheel .

(3) Mount the bobbin winder unit on the arm.

(4) Turn ON the bobbin winder lever and let the head coincide

with the bobbin winder lever .

At that time, the head of the bobbin winder unit setscrew shall be

made to coincide with the bobbin winder lever .

(5) Lightly make the bobbin winder driver wheel lightly contact with

the bobbin winder friction wheel and tighten two bobbin winder

driver wheel setscrews .

(Cautions) 1. When the bobbin winder lever is turned OFF, turn

the hand wheel by hand and confirm that the bobbin

winder shaft does not turn.

2. Never apply grease or such an oily component to

the rubber section of the bobbin winder friction

wheel . Otherwise, this can be a cause of friction.

o If the hand wheel is turned in the

state of OFF, this can be a cause

of abnormal abrasion.

Adjustment Procedure Results of Improper Adjustment

Bobbin winder friction wheel

Part No. 26261503

Loading...

Loading...