– 87 –

(1) Cautions when a dry hook is used

For the dry hook (RP hook), lubrication is given to the hook race with

the use of a specific material.

In the case of continuous high-speed operation, it must be noted that

wear on the race is accelerated.

Lubricant shall not be applied to the race.

If any abrasion is perceived, change the old part with a new one.

(Cautions) The RP hook (dry hook) tends to collect thread chips

and cloth dust, and this can be a case of malfunction

and defective stitches. For this reason, it should be

cleaned periodically.

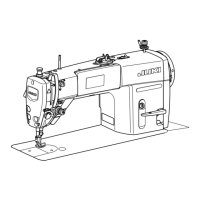

(2) Replacement of the dry hook

If a dry hook is installed according to the specifications of DDL-9000A-

S and A-M , the hook section can be treated as a device conforming

to the dry specifications and sewing can be carried out without lubrication.

* According to (7) Lubrication, set up the hook so that a very small

amount of oil is fed.

1. Take out the lubrication hook.

2. Remove the hook shaft filter asm that is mounted on the hook

shaft tip.

3. Install a lower shaft stop plug screw and O ring which is available

separately.

4. Adjust the amount of hook oil so that lubrication is maintained to a

degree wet with a small amount of hook oil.

(Cautions) 1. Do not drain oil from the oil tank.

2. Be careful not to allow the oil tank to be vacant.

This oil is used also to lubricate the lower shaft front

metal.

o Hook rattling occurs and there are

problems like heat generation and

defective stitches.

o Contamination like black ink is

caused and this becomes a cause

of thread to be stained.

o This is a cause of metal section

seizure.

o This is a cause of metal section

seizure.

6. Dry hook

Adjustment Procedure Results of Improper Adjustment

Dry hook (RP hook)

Part No. Remarks

22890206 Standard type

22890305 Surface treatment type

22890404 Type with a needle guard

Bobbin case part No. for dry hook : 22896252

Part No. Part name

11079506 Lower shaft stop plug screw

RO036080200 O Ring

Loading...

Loading...