A

B

C

D

➊

➋

➍

➌

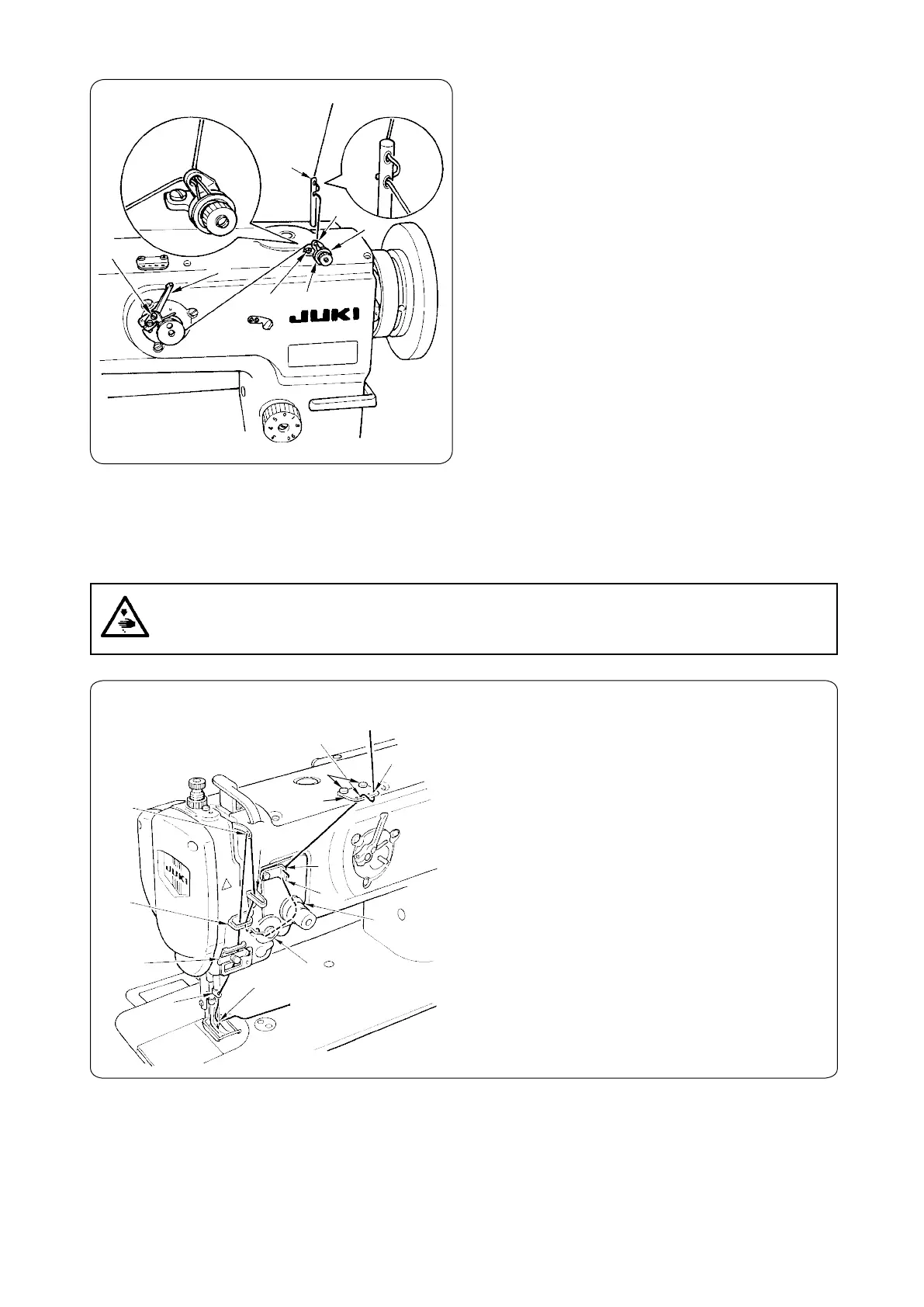

10. WINDING A BOBBIN

1) Pass the thread in the order of

➊

, through

➍

.

Then, wind it several turns round the bobbin.

2) Tilt bobbin winder lever

A

.

3)

Loosen setscrew

B

and adjust the position of the adjusting

plate to wind a bobbin about 80% of its capacity.

4) If the bobbin is wound unevenly, correct it by moving

bobbin winder thread guide

C

back or forth.

Then, tighten setscrews

D

.

5) When the bobbin is filled up, the bobbin winder lever

automatically releases the bobbin and the bobbin

winder stops running.

– 22 –

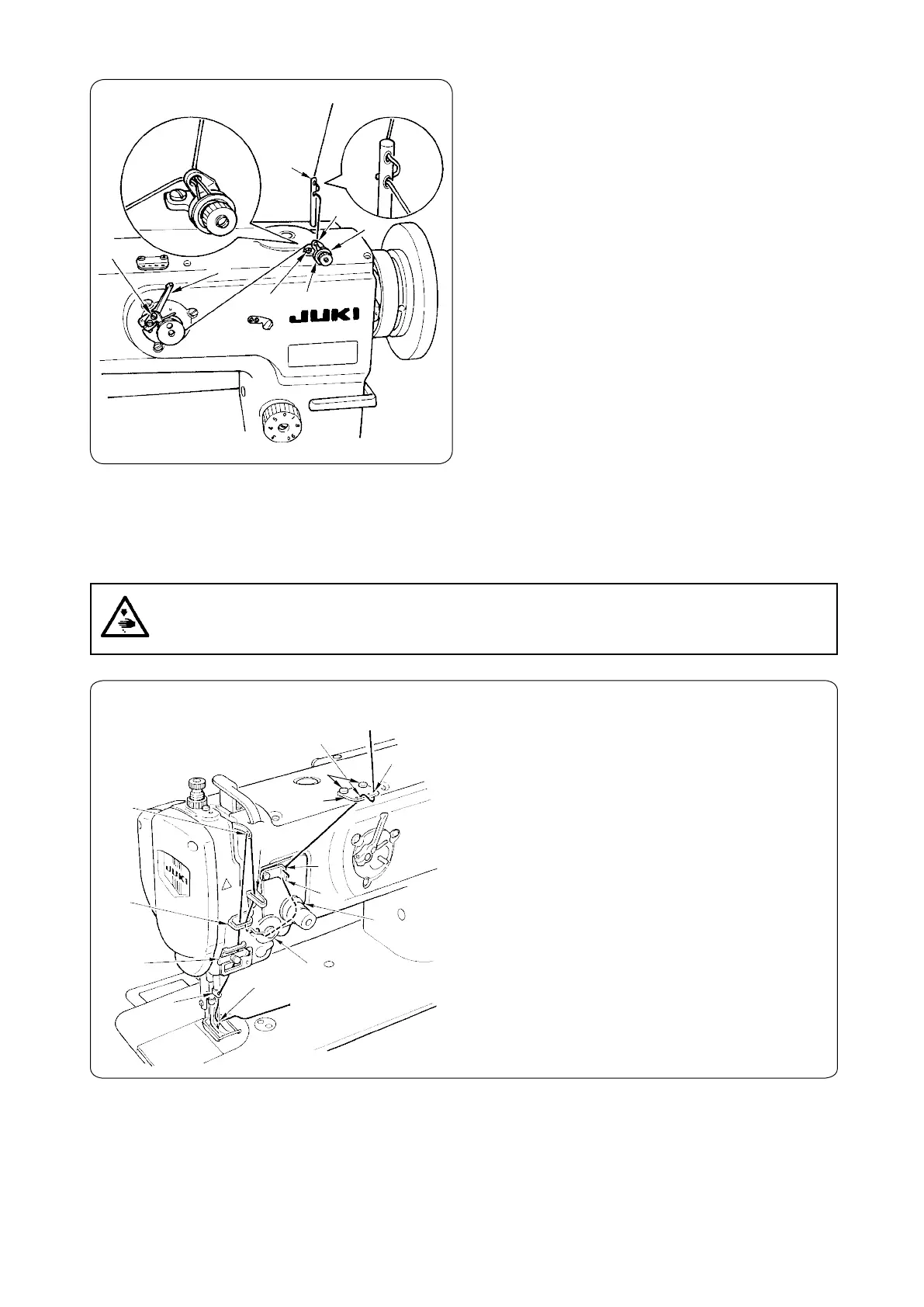

1. Attach arm thread guide

A

to the top cover with

setscrew

B

.

2. Thread the machine head following the order of 1

through

13

as shown in the illustration given above.

*

Pass thread through the right side of thread guide

11

.

DNU-1541

DNU-1541S

1

2

5

6

8

9

* 11

12

13

3

4

10

7

A

B

11. THREADING THE MACHINE HEAD

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the follow-

ing work after turning the power off and ascertaining that the motor is at rest.

Edit: Corrects an error. The official manual refers to points 6, 9, 8, 9 & 10 (should be 6, 7, 8, 9 & 10. I.e.,

where the thread passes through the thread-guide twice – going up to the take-up arm, and down to the

needle – is referred to as points 9 & 10 in the manual. Should be 7 & 10 as shown above.). The 1541H

diagram (next page) doesn’t have this error.

– 23 –

Loading...

Loading...