– 3 –

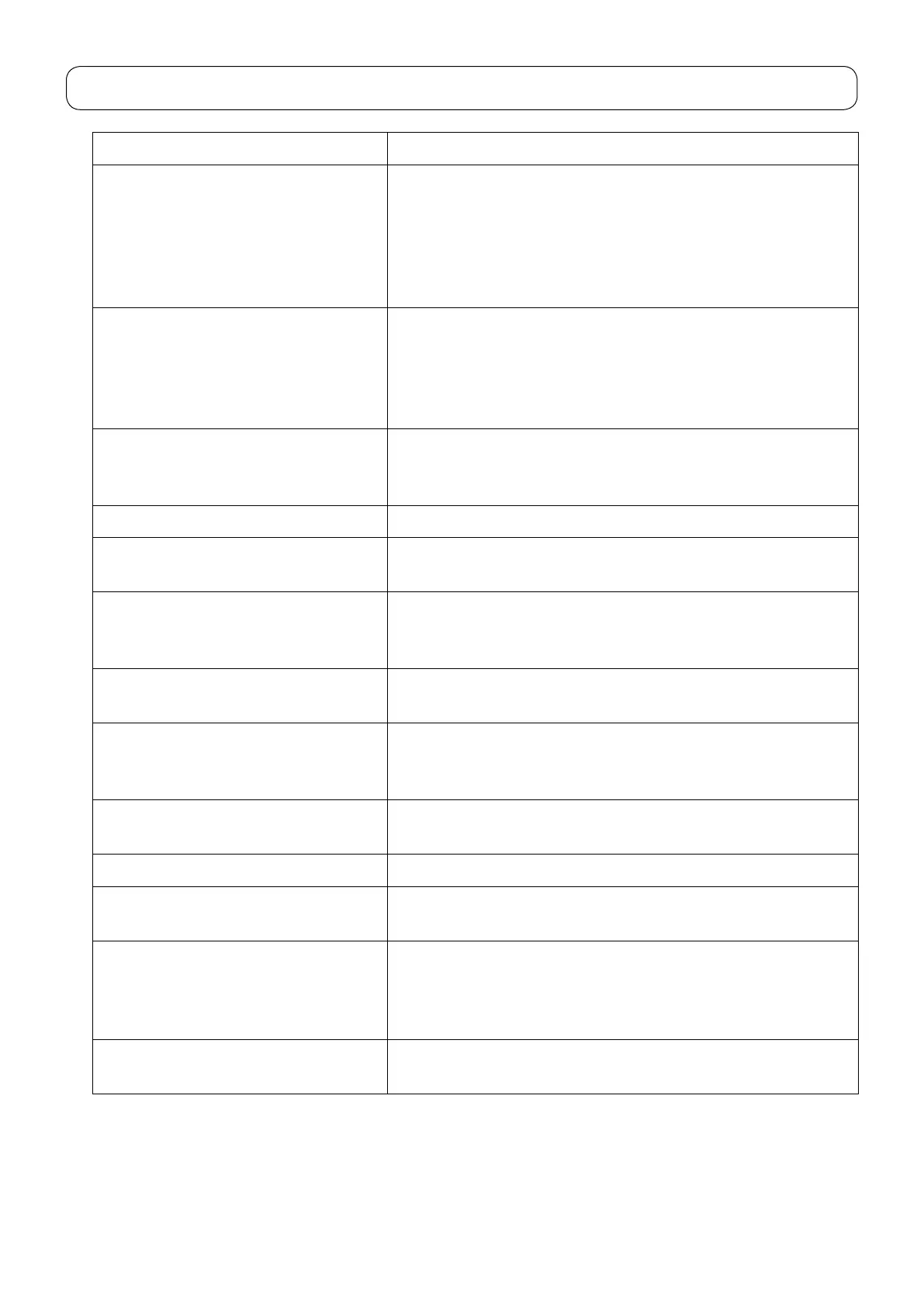

[2] Search by trouble (related to mechanical components)

Phenomenon Item to be checked

Faulty thread tension 6-8: Position of the hook rotation stopper plate

6-9: Adjusting the bobbin thread tension

6-10-2: Pretension disk opening amount

6-10-3: Tension disk opening amount

6-10-4: Base tension opening amount

6-11: Adjusting the needle thread tension

Stitch skipping 6-1: Adjusting the needle bar height

6-2: Adjusting the needle entry point

6-5: Feed timing

6-6: Timing between the needle and the hook

6-7: Clearance between the needle and the blade point of hook

Thread breakage 6-1: Adjusting the needle bar height

6-6: Timing between the needle and the hook

6-8: Position of the hook rotation stopper plate

Hitch stitch 6-2: Adjusting the needle entry point

Faulty material feed 6-3: Feed dog height

6-15: Adjusting the presser bar height

Contact between needle and throat plate

or hook

6-2: Adjusting the needle entry point

6-5: Feed timing

6-6: Timing between the needle and the hook

Faulty pattern shape 6-3: Feed dog height

6-18: Longitudinal feed

Faulty automatic thread trimming 6-17-1: Lateral position of the thread trimming mechanism base

6-17-2: Phase of the catching unit driving cam

6-17-3: Replacing the thread trimming blade

Faulty operating noise 6-4: Timing belt

6-16: Motor belt

Needle threader 6-12: Vertical position of the needle threading hook

Fails to start sewing 6-20-1: Auto-lifter cam lever

6-20-3: Adjusting the height of the presser foot when it is lifted

Faulty automatic presser foot lifting height 6-19: Knee lifting wire

6-20-1: Auto-lifter cam lever

6-20-2: Presser-lifter position sensor

6-20-3: Adjusting the height of the presser foot when it is lifted

Straight stitch slide plate 6-21-1: Adjusting the position of the straight stitch slide plate

6-21-2: Straight stitch slide plate sensor PCB

Loading...

Loading...