-

46

-

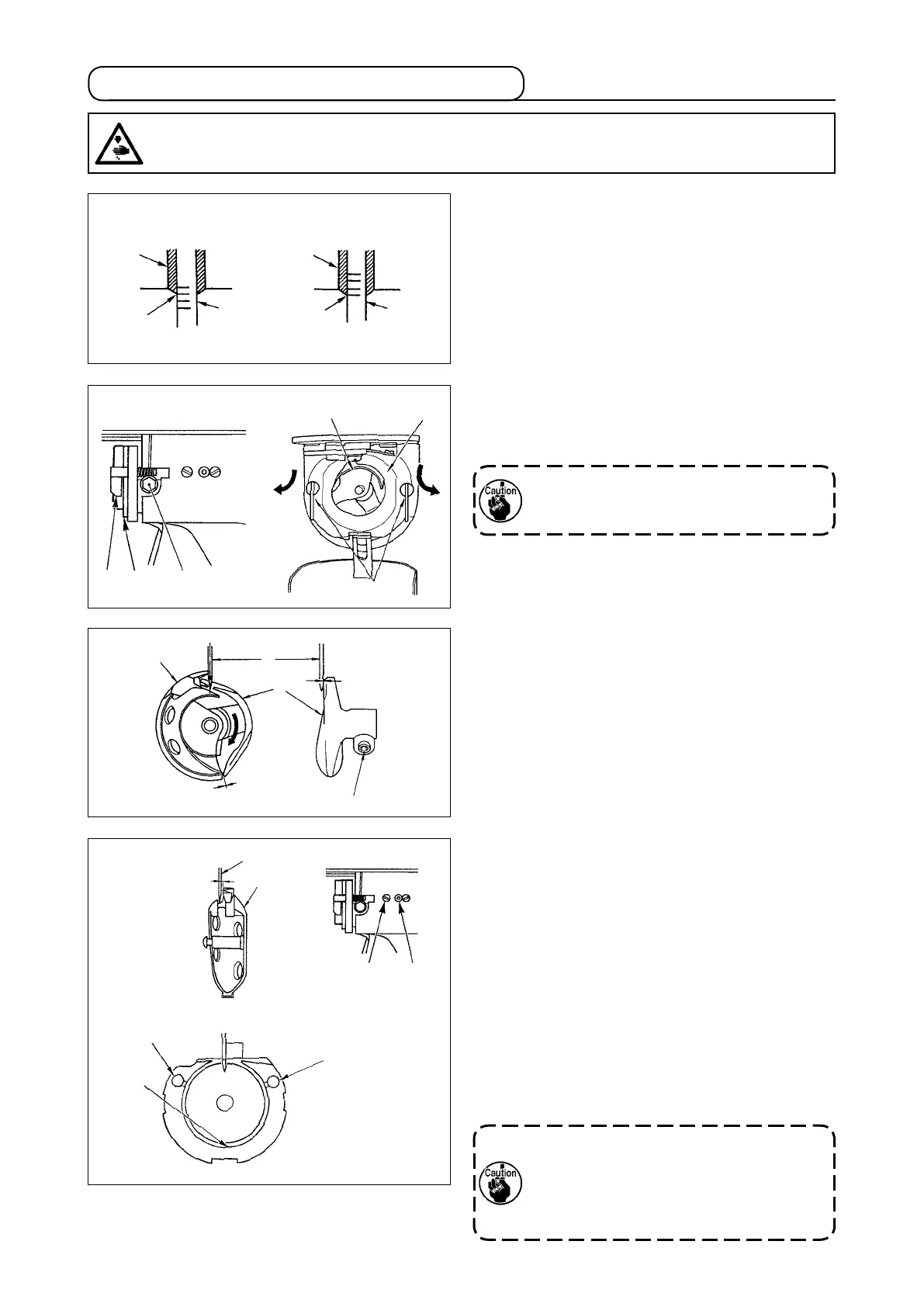

1) Turn the handwheel by hand. When nee-

dle bar

❶

has gone up, adjust so that lower

marker line

❷

engraved on the needle bar

aligns with the bottom end of the needle bar

bushing

❸

, lower.

7-2. Adjusting the needle-to-shuttle relation

❹

Relation between needle and engraved lines

❶

❷

❸

❶

❷

❸

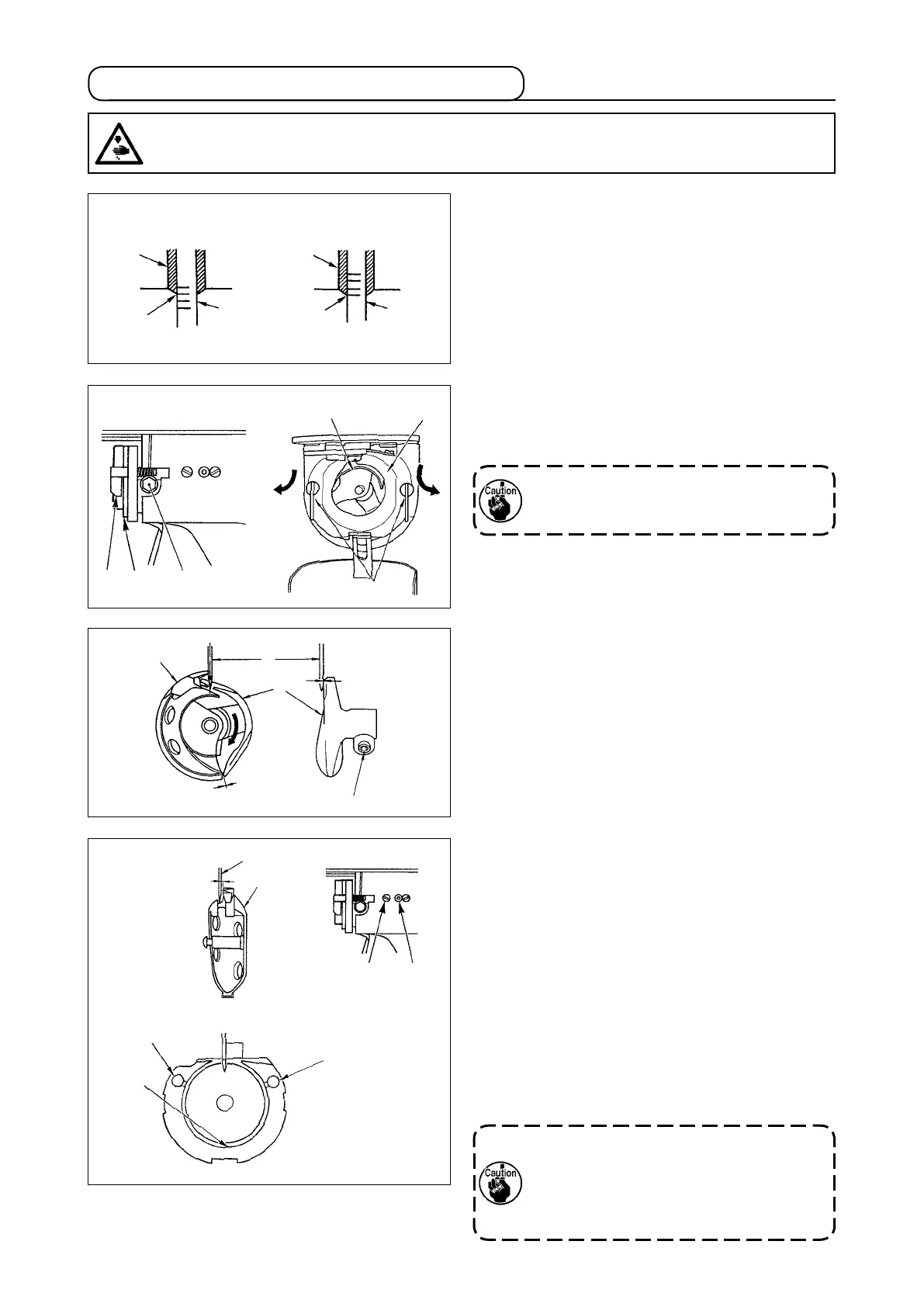

3) Adjust so that the blade point of inner hook

❹

aligns with the center of needle

❺

, and that

a clearance of 0 mm is provided between the

front end of the driver and the needle as the

front end face of driver

❻

receives the needle

to prevent the needle from being bent. Then

tighten setscrew

of the driver.

0.05 to 0.1 mm

7.5 mm

❺

❹

❼

❽

0 mm

0 mm

❺

❹

❻

❾

2) Loosen setscrew

in the driver. Open inner

hook pressers

to the right and left, and

remove inner hook presser

.

At this time, be careful not to let inner

hook

❹

come off and fall.

4) Loosen setscrew

❼

of the shuttle, and adjust

the longitudinal position of the shuttle. To do

this adjustment, turn shuttle race adjusting

shaft

❽

clockwise or counterclockwise to

provide a 0.05 to 0.1 mm clearance between

needle

❺

and the blade point of inner hook

❹

.

5) After adjusting the longitudinal position of the

shuttle, further adjust to provide a 7.5 mm

clearance between the needle and the shuttle

by adjusting the rotating direction. Then tight-

en setscrew

❼

of the shuttle.

If the sewing machine is left unused for a

long time, or after clearing the area sur-

rounding the hook section, apply a little

quantity of oil to race section

❾

and felt

before using the sewing machine.

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

Loading...

Loading...