-

62

-

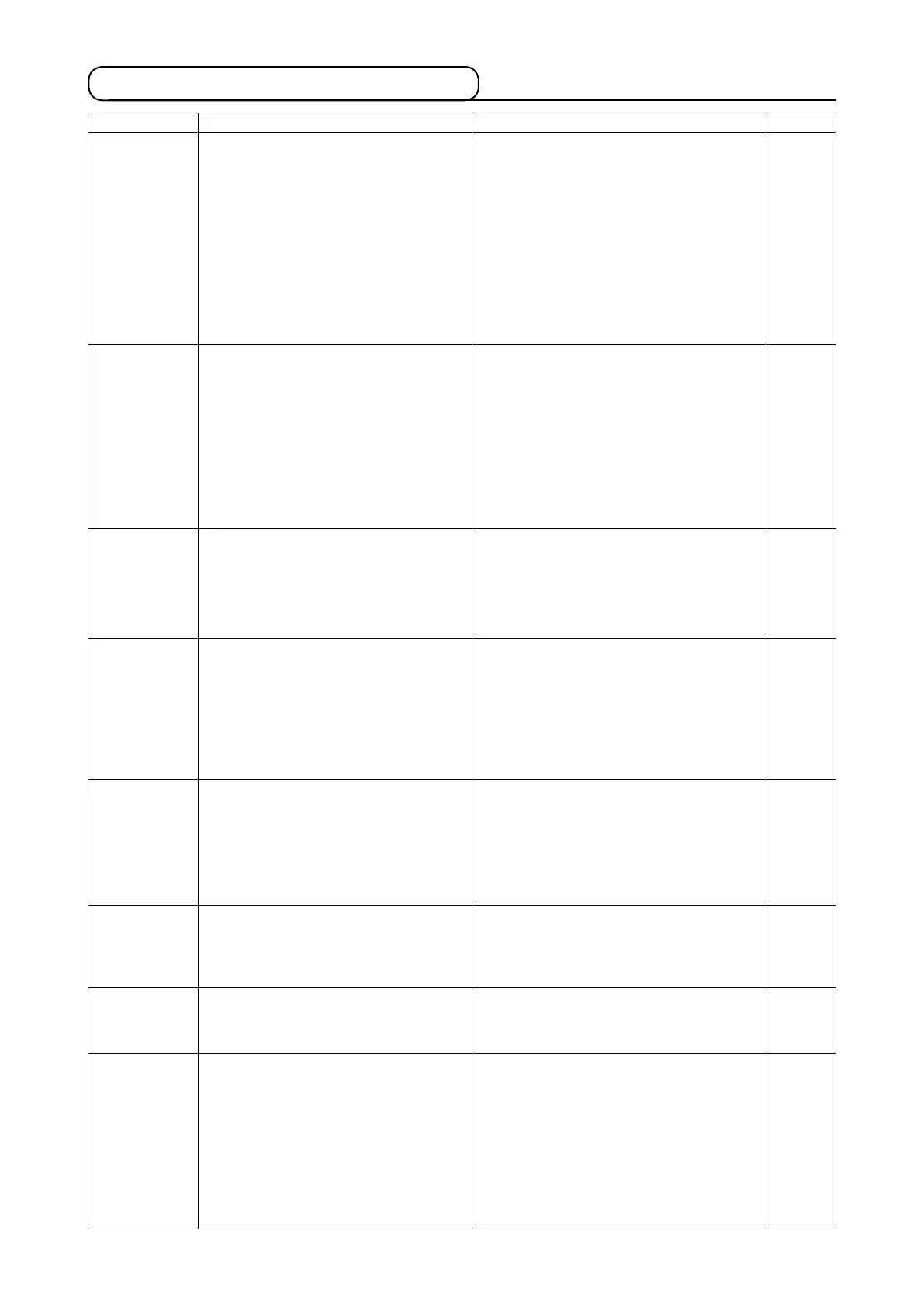

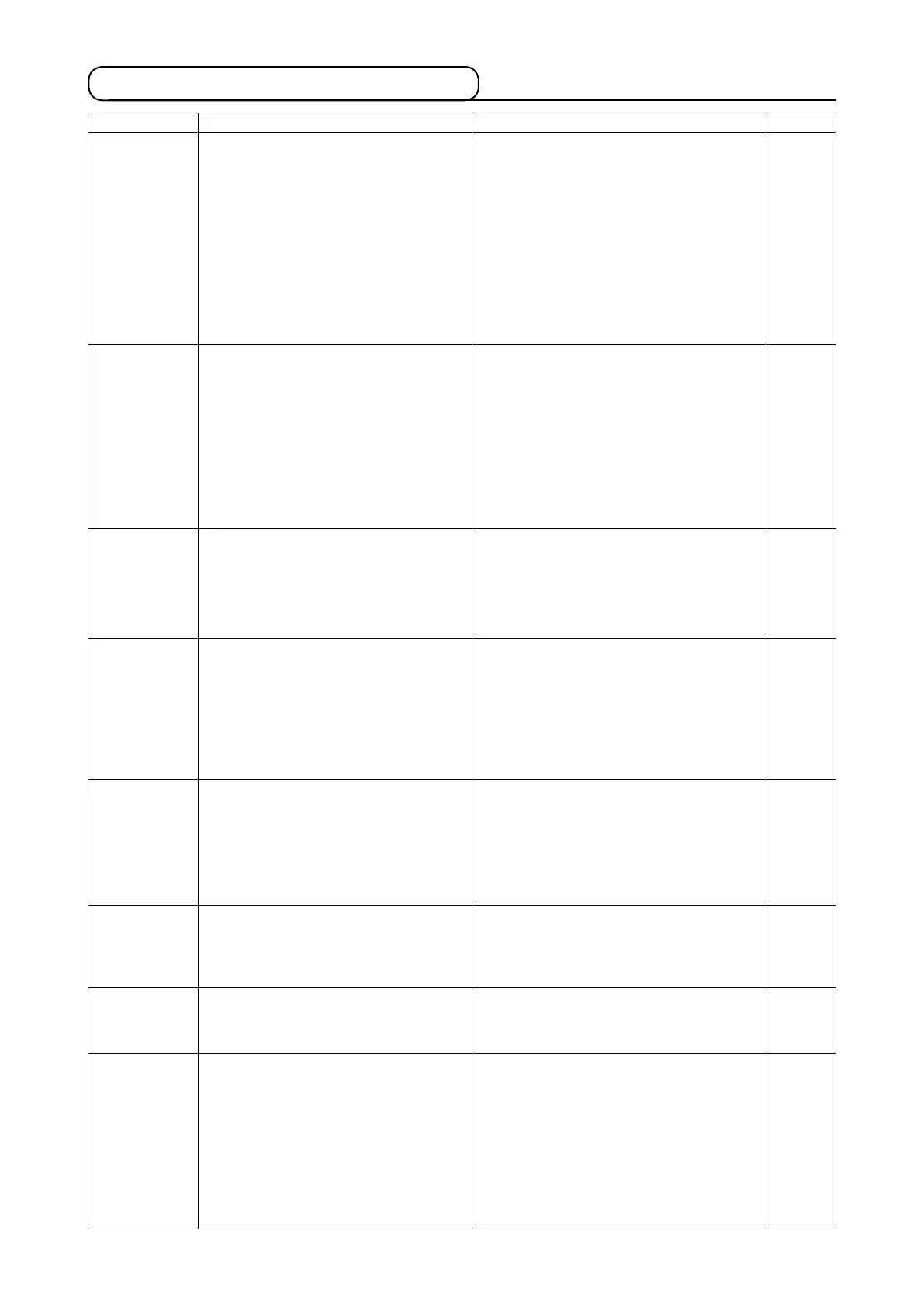

9-4. Troubles and corrective measures

Trouble Cause Corrective measures Page

1. The needle

thread slips

off at the start

of bar-tacking.

①

Stitches are slipped at the start.

◦

Adjust the clearance between the needle

and the shuttle to 0.05 to 0.1 mm.

46

◦

Set soft-start sewing at the start of bartack-

ing.

52

②

The needle thread remaining on the

needle after thread trimming is too

short.

◦

Correct the thread tension release timing of

the thread tension controller No. 2.

48

◦

Increase the tension of the thread take-

up spring, or decrease the tension of the

thread tension controller No. 1.

17, 18

③

The bobbin thread is too short.

◦

Decrease the tension of the bobbin thread. 17

◦

Increase the clearance between the needle

hole guide and the counter knife.

47

2. Thread often

breaks or

synthetic ber

thread splits

nely.

①

The shuttle or the driver has scratches.

◦

Take it out and remove the scratches using

a ne whetstone or buff.

②

The needle strikes the work clamp foot.

◦

Correct the position of the work clamp foot.

③

Fibrous dust is in the groove of the

shuttle race.

◦

Take out the shuttle and remove the brous

dust from the shuttle race.

④

The needle thread tension is too high.

◦

Reduce the needle thread tension. 17

⑤

The tension of the thread take-up

spring is too high.

◦

Reduce the tension. 17

⑥

The synthetic ber thread melts due to

heat generated on the needle.

◦

Use silicone oil. 64

3. The needle

often breaks.

①

The needle is bent.

◦

Replace the bent needle. 15

②

The needle is too thin for the material.

◦

Replace it with a thicker needle according

to the material.

③

The driver excessively bends the nee-

dle.

◦

Correctly position the needle and the shut-

tle.

46

④

The feed timing is too late.

◦

Advance the feed operation timing. 52

4. Threads are

not trimmed.

①

The counter knife is dull.

◦

Replace the counter knife.

②

The difference in level between the

needle hole guide and the counter knife

is not enough.

◦

Increase the bend of the counter knife.

③

The moving knife has been improperly

positioned.

◦

Correct the position of the moving knife. 47

④

The last stitch is skipped.

◦

Correct the timing between the needle and

the shuttle.

46

5. Stitch skipping

often occurs.

①

The motions of the needle and shuttle

are not properly synchronized.

◦

Correct the positions of the needle and

shuttle.

46

②

The clearance between the needle and

shuttle is too large.

◦

Correct the positions of the needle and

shuttle.

46

③

The needle is bent.

◦

Replace the bent needle. 15

④

The driver excessively bends the nee-

dle.

◦

Correctly position the driver. 46

6. The needle

thread comes

out on the

wrong side of

the material.

①

The needle thread tension is not high

enough.

◦

Increase the needle thread tension. 17

◦

Retard the feed operation timing. 52

②

The needle thread after thread trimming

is too long.

◦

Increase the tension of the thread tension

controller No. 1.

17

7. Threads

break at time

of thread trim-

ming.

①

The moving knife has been improperly

position.

◦

Correct the position of the moving knife. 47

8. When

synthetic

ber thread is

used, at the

start or end

of sewing,

needle thread

rises or

remaining of

needle thread

is excessive.

①

In case of synthetic ber thread, the

thread is harder than other threads and

penetration resistance to material is

small.

◦

When making a pattern, set the sewing

pitch at the start and end of sewing to 1

mm or less.

Loading...

Loading...