3.3 Parameter description

3.3.1 Runtime and error monitoring

The ru-parameters serve for monitoring of the program ow.

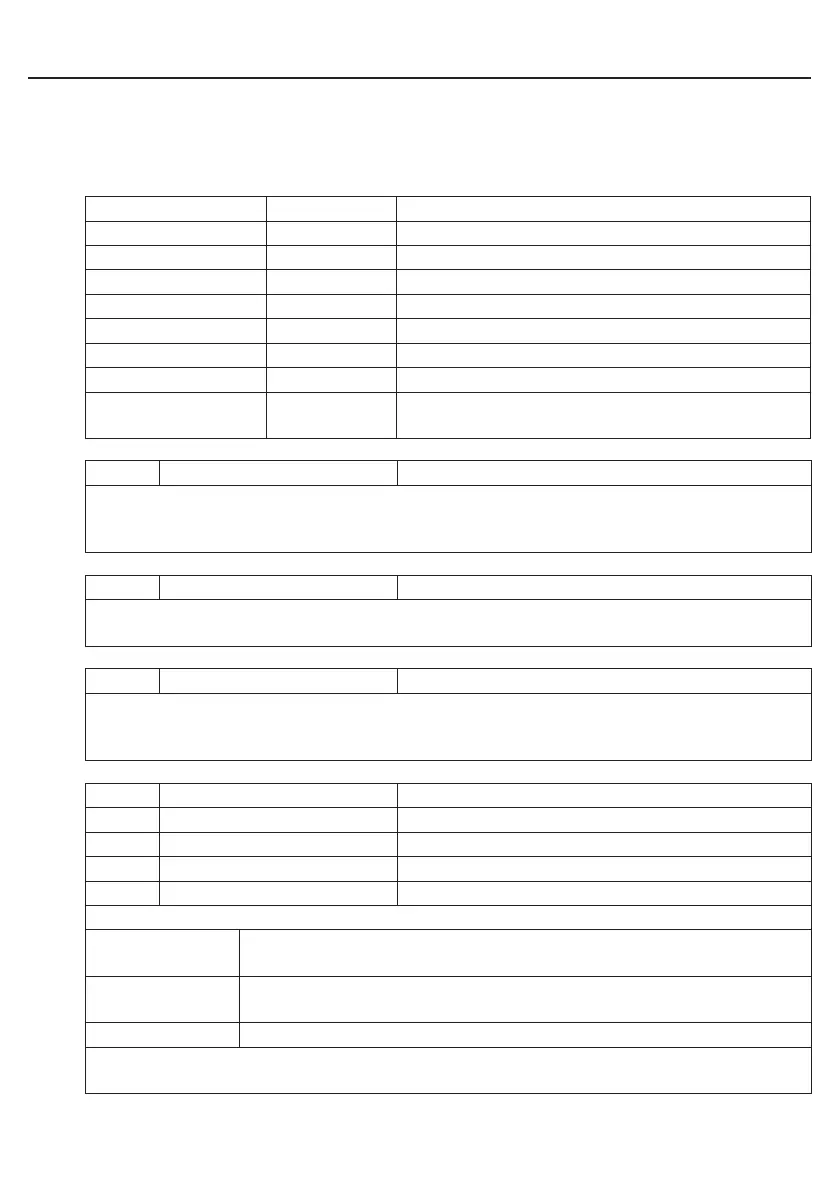

ru.00 Status Address 0200h

Program status no prog no program loaded

prog OK program loaded

prog corrupt program checksum error

Control status run Program runs

Stop Program stopped

breakpoint Program is on break point

Error status err_cyctime The adjusted cycle time was exceeded

err_watchdog The length of the last PLC cycle exceeded the

maximum value, the PLC program was stopped.

ru.01 cycle time Address 0201h

This parameter indicates the cycle time adjusted by the PLC program in milliseconds.

This value is also used for the cycle time monitoring, a value of 0 ms means a free-run-

ning PLC program without cycle time monitoring.

ru.02 axis mode Address 0202h

The parameter indicates the axis conguration adjusted by the PLC program. There is a

differentiation between normal- and synchronous/cyclic operation.

ru.03 axis errors Address 0203h

The parameter indicates the axes which did not respond. This can have been released by

interruption of the cable to the axis or by switching off the axis. The value 0 means that all

monitored axes are connected correctly.

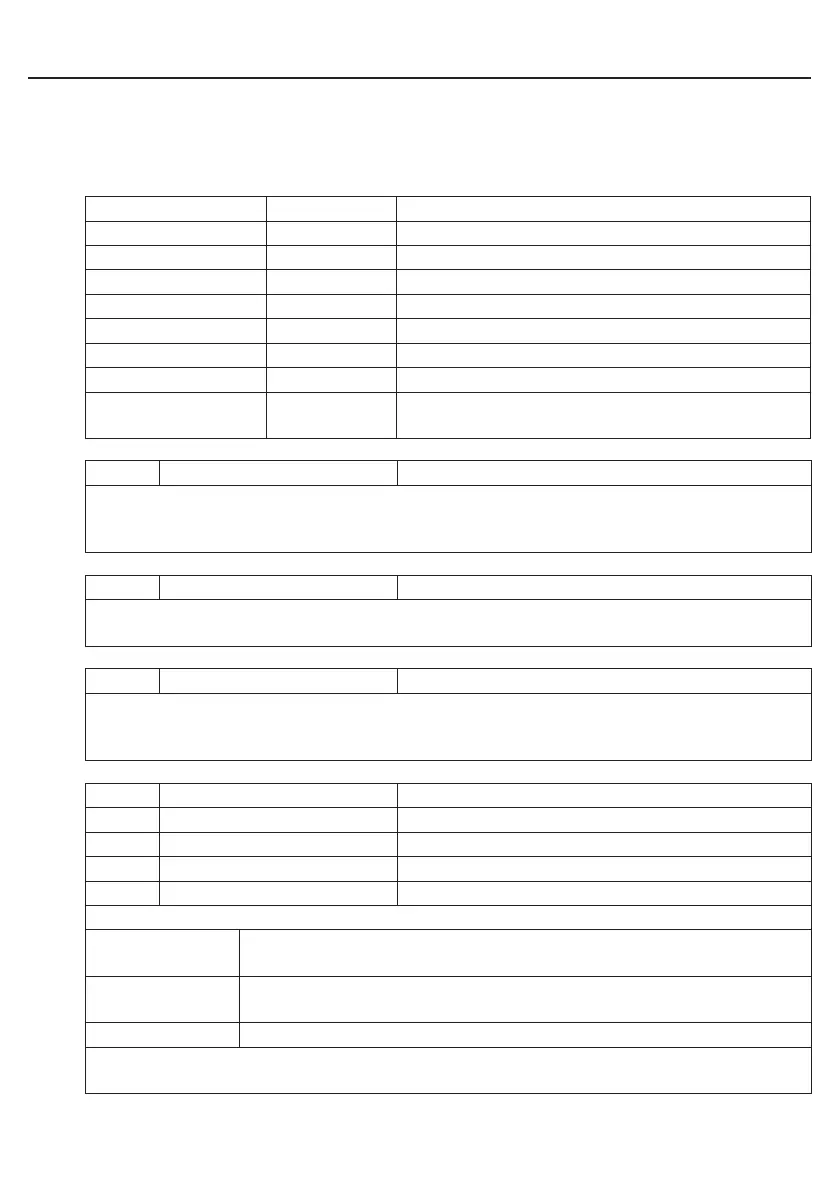

ru.04 min. process time Address 0204h

ru.05 max. process time Address 0205h

ru.06 response time Address 0206h

ru.07 process time Address 0207h

ru.08 idle time Address 0208h

The cycle time of a PLC program ow is composed of:

response time Time of recognizing the new program cycle up to the call of the PLC

program

process time Time, when the PLC program as well as all accesses by CoDeSys

and COMBIVIS are processed.

idle time Remaining time up to the next program cycle.

Parameter ru.04 / ru.05 displays the minimum/maximum process time and can be reset

by writing of any value.

Loading...

Loading...