CAUTION

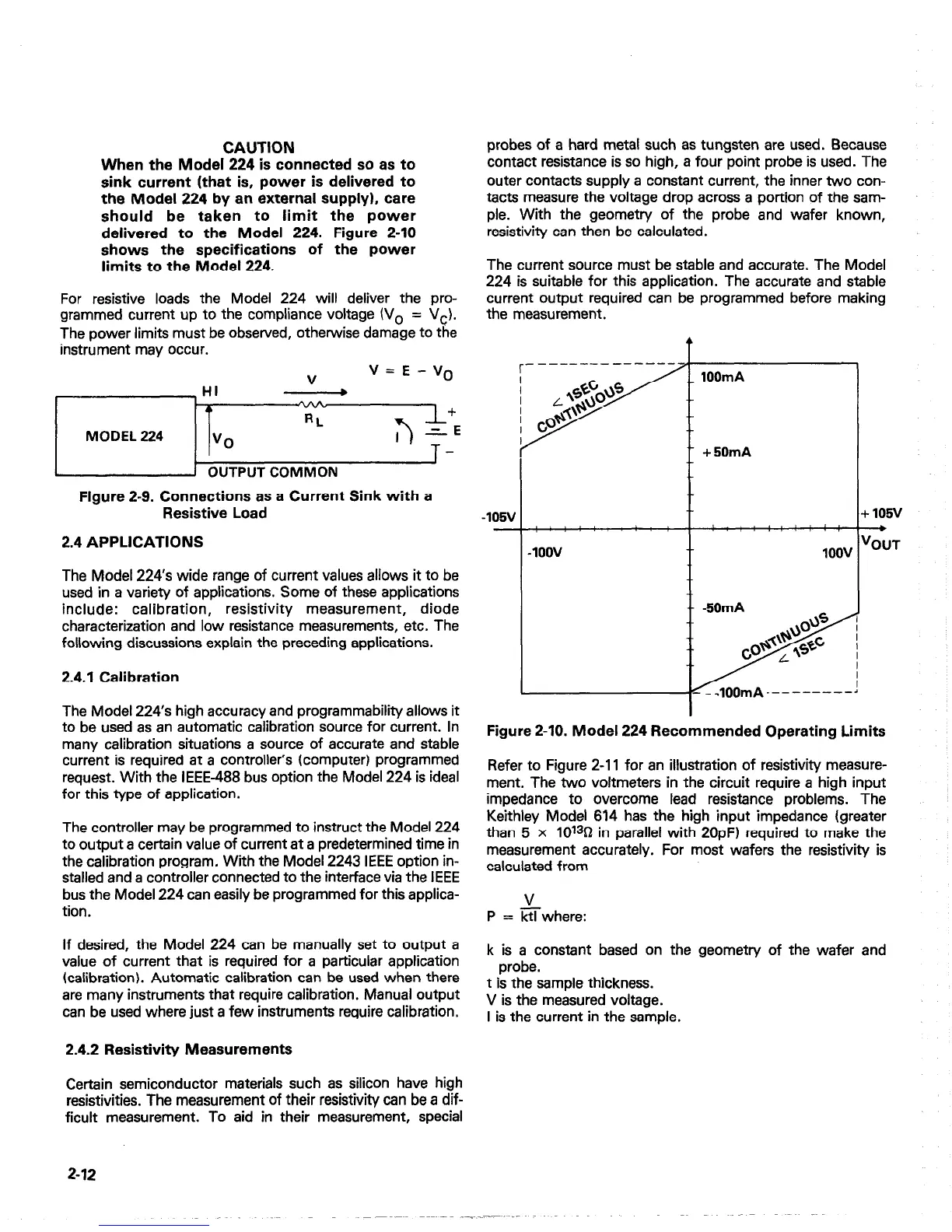

When the Model 224 is connected so as to

sink current (that is, power is delivered to

the Model 224 by an external supply). care

should be taken to limit the power

delivered to the Model 224. Figure 2-10

shows the specifications of the power

limits to the Model 224.

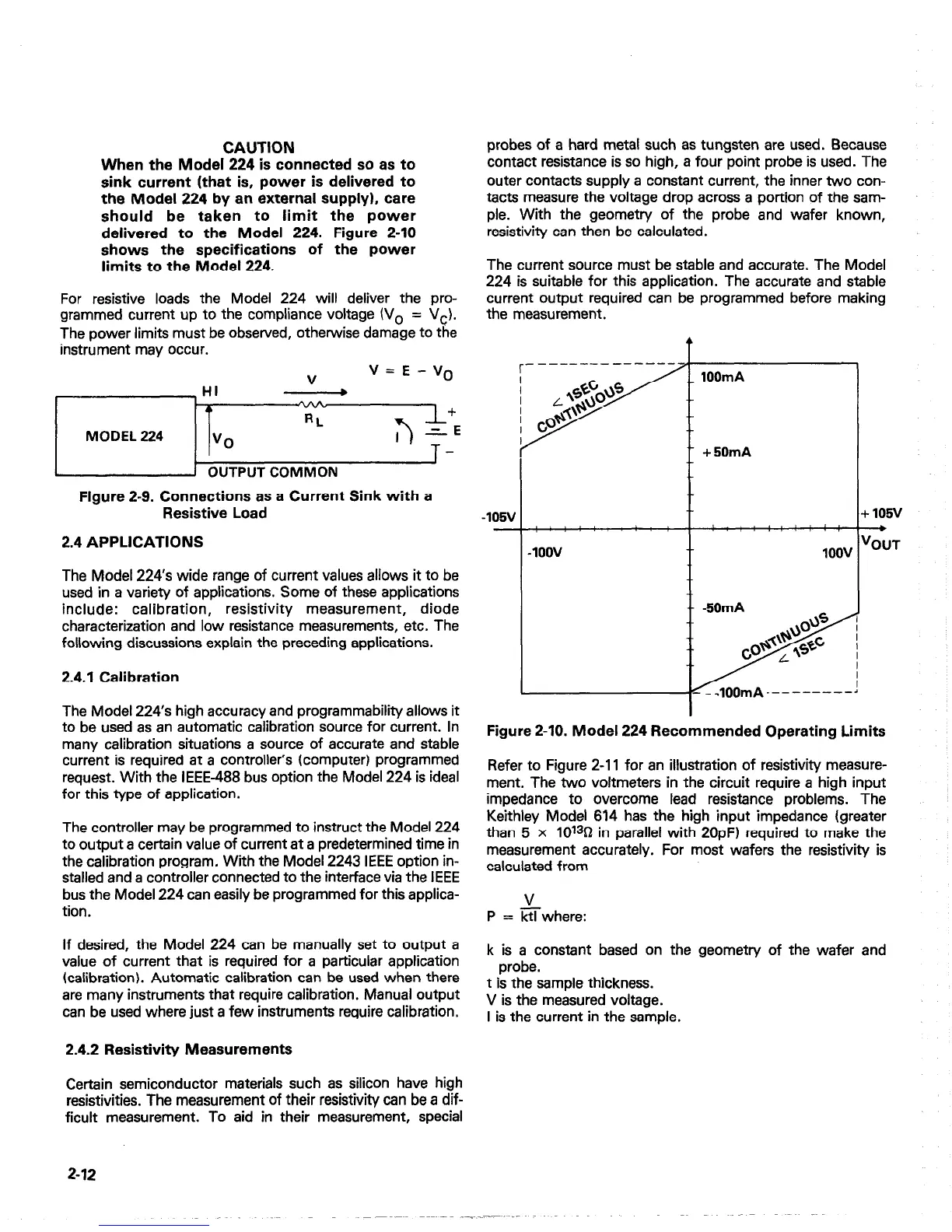

For resistive loads the Model 224 will deliver the pro-

grammed current up to the compliance voltage (V, = Vc).

The power limits must be observed, otherwise damage to the

instrument may occur.

r

MODEL 224

J

OUTPUT COMMON

Figure 2-9. Connections as a Current Sink with a

Resistive Load

2.4 APPLICATIONS

The Model 224’s wide range of current values allows it to be

used in a variety of applications. Some of these applications

include: calibration,

resistivity measurement, diode

characterization and low resistance measurements, etc. The

following discussions explain the preceding applications.

2.4.1 Calibration

The Model 224’s high accuracy and programmability allows it

to be used as an automatic calibration source for current. In

many calibration situations a source of accurate and stable

current is required at a controller’s (computer) programmed

request. With the IEEE-488 bus option the Model 224 is ideal

for this type of application.

The controller may be programmed to instruct the Model 224

to output a certain value of current at a predetermined time in

the calibration program, With the Model 2243 IEEE option in-

stalled and a controller connected to the interface via the IEEE

bus the Model 224 can easily be programmed for this applica-

tion.

If desired, the Model 224 can be manually set to output a

value of current that is required for a particular application

(calibration). Automatic calibration can be used when there

are many instruments that require calibration. Manual output

can be used where just a few instruments require calibration.

2.4.2 Resistivity Measurements

Certain semiconductor materials such as silicon have high

resistivities. The measurement of their resistivity can be a dif-

ficult measurement. To aid in their measurement, special

2-12

probes of a hard metal such as tungsten are used. Because

contact resistance is so high, a four point probe is used. The

outer contacts supply a constant current, the inner two con-

tacts measure the voltage drop across a portion of the sam-

ple. With the geometry of the probe and wafer known,

resistivity can then be calculated.

The current source must be stable and accurate. The Model

224 is suitable for this application. The accurate and stable

current output required can be programmed before making

the measurement.

r-

4

,100v

IOOV

T

.- -5OmA

,

b 105v

--+

{OUT

Figure 2-10. Model 224 Recommended Operating Limits

Refer to Figure 2-11 for an illustration of resistivity measure-

ment. The two voltmeters in the circuit require a high input

impedance to overcome lead resistance problems. The

Keithley Model 614 has the high input impedance (greater

than 5 x 10130 in parallel with 2OpF) required to make the

measurement accurately. For most wafers the resistivity is

calculated from

V

P = ktlwhere:

k is a constant based on the geometry of the wafer and

probe.

t is the sample thickness.

V is the measured voltage.

I is the current in the sample.

Loading...

Loading...