2600S-900-01 Rev. C / January 2008 Return to Section Topics 3-3

Series 2600 System SourceMeter

®

Instruments User’s Manual Section 3: Test Script Processor Interaction

Reading the buffer – Test data is stored in a buffer. See “How do I use the buffer?” on page 1-16

for details on recalling test data.

How do I interact with scripts using Test Script Builder?

Reference See “Using the Test Script Builder” in Section 2 of the Series 2600 Reference

Manual for details on the Test Script Builder.

The following function for factory script “KIGeneral” is stored in the non-volatile memory of the

Series 2600:

PulseVMeasureI(smu, bias, level, ton, toff, points)

The above function performs a specified number of pulse V, measure I cycles:

• Sets the smu to output bias volts and dwell for ton seconds.

• Sets the smu to output level volts and dwell for ton seconds.

• Performs current measurement with the source at level volts.

• Sets the smu to output bias volts for toff seconds.

• Repeats the above sequence for points pulse-measure cycles.

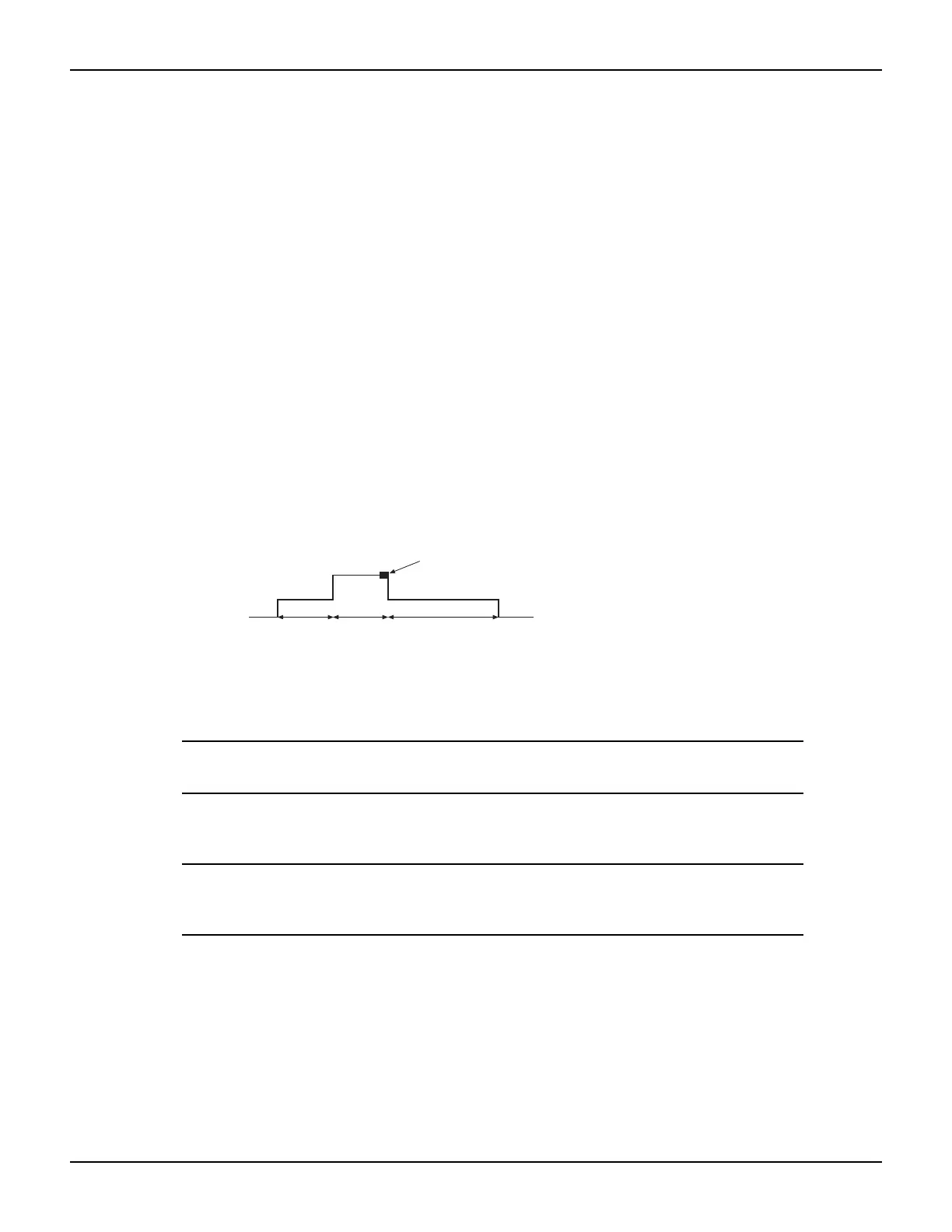

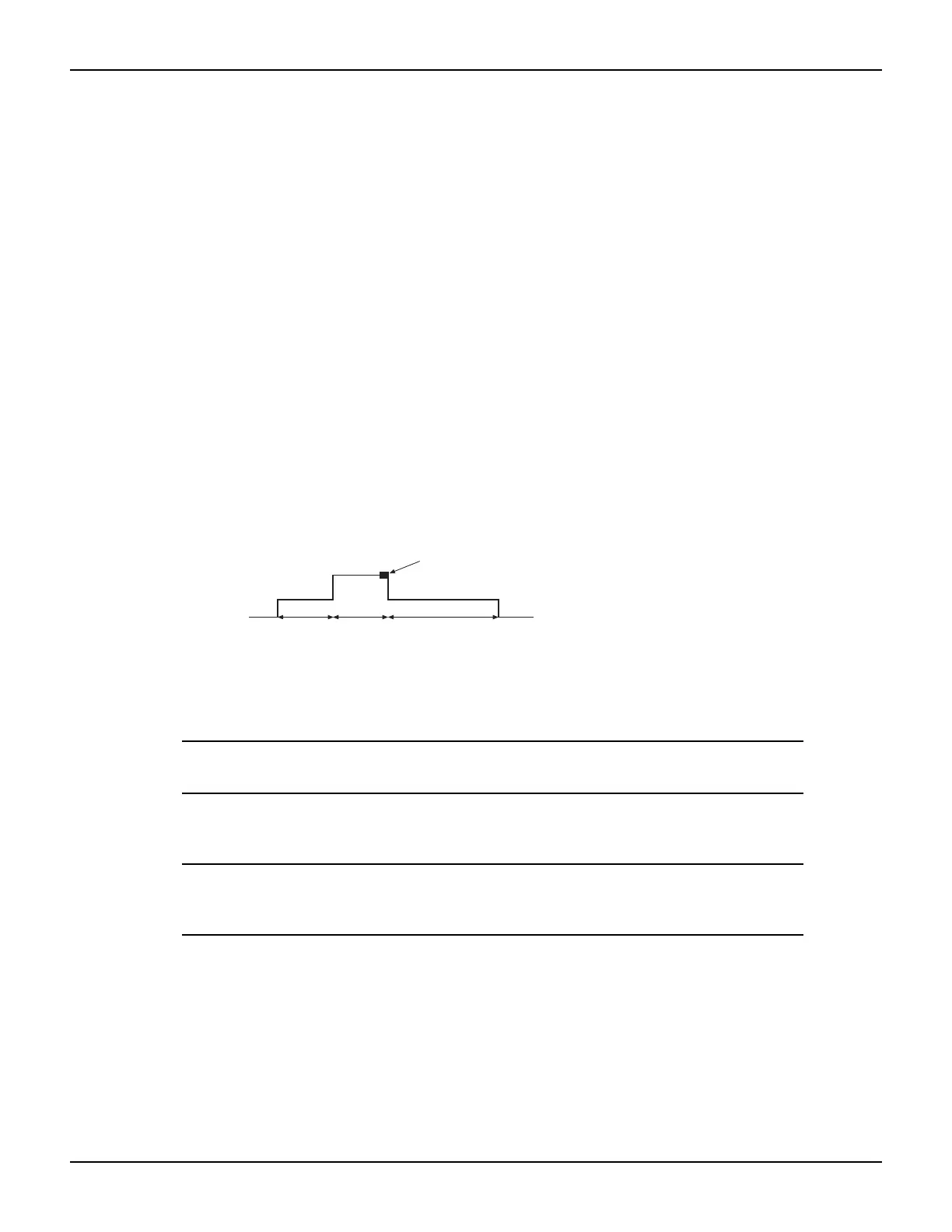

Figure 3-1 shows one pulse-measure cycle for the function.

Figure 3-1

Pulse-measure cycle for the

level

bias

ton

bias

ton toff

Current measurement

PulseVMeasureI function

Running a factory script

Reference See “Factory scripts” in Section 2 of the Series 2600 Reference Manual for details

on running factory scripts.

NOTE All commands to run a factory script are to be executed from the

Instrument Console of the Test Script Builder.

The following steps explain how to run the PulseVMeasureI function and read the data stored in

the buffer.

NOTE The “KIGeneral” factory script is an autorun script. The script runs

automatically when the Series 2600 is turned on. The functions of the

script are ready to be called.

Step 1: Call the function

The following are example parameters for the PulseVMeasureI function which will perform three

pulse voltage, measure current cycles:

smu SMU A

bias -1V

level 1V

ton 1ms

toff 2ms

Loading...

Loading...