TP-5594 5/95 Scheduled Maintenance 3-7

Fuel Filter

(Plastic In-Line Type

Supplied Loose)

The fuel filter, supplied loose with the unit, serves as a

preliminary source to remove dirt and metal particles

from the fuel system before they reach the electric fuel

pump. If the fuel filter is clogged with debris, the

generatormay bedifficultto start ormayrunrough. The

service life of the fuel filter is solely dependent on the

quality of the diesel fuel used and the amount of debris

entering the fuel system when refueling. As part of a

regular maintenance program, check and/or replace

fuelfilterevery3monthsor100hours of operation. The

fuel filter cannot becleaned and must bereplaced iffuel

starvation or poor engine performance is evident.

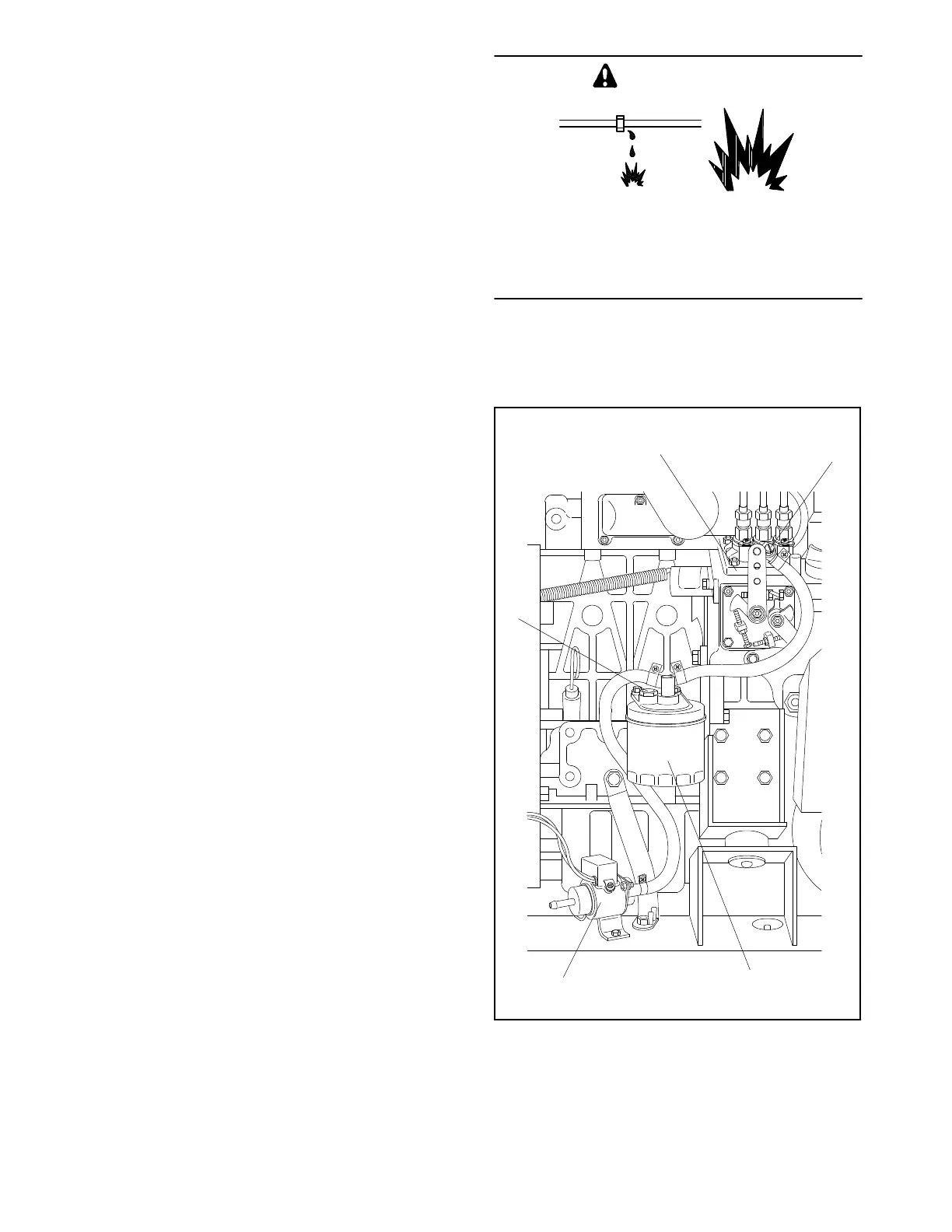

Bleeding the Fuel System

If the generator set engine runs out of fuel, air leaks

developinthesuctionsideof the fuel system, or thefuel

filter is replaced, it will be necessary to bleed the entire

system to prevent starting failures and/or erratic

operation. See Figure 3-7 and refer to the following

procedure.

1. Fill the fuel tank.

2. Loosen the small vent screw a few turns on fuel

filter.

3. Usingstartswitchonthecontroller,operatethefuel

pump until fuel, free from air bubbles, flows from

this point. Tighten vent screw.

4. Loosen the line connection (bleed point) at fuel

injection pump inlet.

5. Usingstartswitchonthecontroller,operatethefuel

pump until fuel, free from air bubbles, flows from

this point. Tighten line connection.

Explosive fuel vapors.

Can cause severe injury or death.

Useextreme carewhenhandling,storing,

and using fuels.

WARNING

Explosive fuel vapors can cause severe injury or

death. Spilled fuel can cause an explosion. Use a

container to catch fuel whendraining fuelsystem. Wipe

up all spilled fuel after draining system.

1-932

1

2

3

4

5

1. Fuel Injection Pump

2. Line Connection (Bleed Point)

3. Fuel Filter

4. Electric Fuel Pump

5. Vent Screw

Figure 3-7. Bleeding Fuel System

Loading...

Loading...