201Section 10 Governor AdjustmentsTP-6356 4/12

h. The supplied CD-ROM contains a Governor

Parameter Summary for each generator set/

engine combination. Print a copy of this

summary as it provides the data necessary for

programming the parameters for each specific

generator set. See Section 10.6, Parameter

Definitions, for detailed explanations of each

parameter and Section 10.7, Parameter

Defaults Reference.

D If Governor Parameter Summary includes

your generator set/engine combination, go to

step 4.

D If the Governor Parameter Summary DOES

NOT include your generator set/engine

combination, go to Section 10.9, Calibration

Instructions.

Note: It is recommended to connect a load

bank to the generator set in an effort to

provide varying loads.

4. Program the governor controller and save the files.

a. Use the part number data determined in step 1

and select the Parameter Text file by clicking

File-Open-“?.Txt”

The Read All values on the PC screen are the

values shown on the printed Parameter

Summary form.

b. Click Write All. The selected parameter text file

is then sent to the governor controller.

c. Save and store this parameter text file on your

PC hard drive, floppy disk, and/or CD-ROM for

future reference.

5. Disconnect the governor controller from the user-

supplied PC.

a. Check that the generator set master switch is in

the OFF position.

b. Move the white lead/70A from the normally

closed K5 contact back to the normally open K5

contact. See Figure 10-16.

c. Disconnect the supplied cable included in the

kit from the user-supplied PC 9-pin RS-232

serial port and the governor controller RJ11

connector (phone jack).

d. Store the cable and CD-ROM together for later

use as needed.

10.5.15 Troubleshooting

See Section 10.10, Diagnostics and Troubleshooting,

for help in diagnosing generator set/engine problems

relating to the governor controller.

10.6 Parameter Definitions

(Digital Isochronous Governor

Programming Kit GM39344)

Use this section for definitions of each of the calibration

values. Section 10.7, Parameter Defaults Reference,

lists the default settings.

When changing values using the keypad, the PST

display on the user’s PC will not automatically update.

To refresh the PST display, the user must select a

different parameter with the PC mouse and then go back

to the desired value. The PST provides Read All button

which will refresh all of the parameter values.

1. Number of flywheel teeth. Enter the value from

the Governor Parameter Summary. This display

is not required. Displayed speeds can be changed

between Hz and rpm.

2. Set Speed A. Enter the value from the Governor

Parameter Summary.

3. Set Speed B (load share model only). Use the

default value.

4. Idle Speed. Enter the value from the Governor

Parameter Summary.

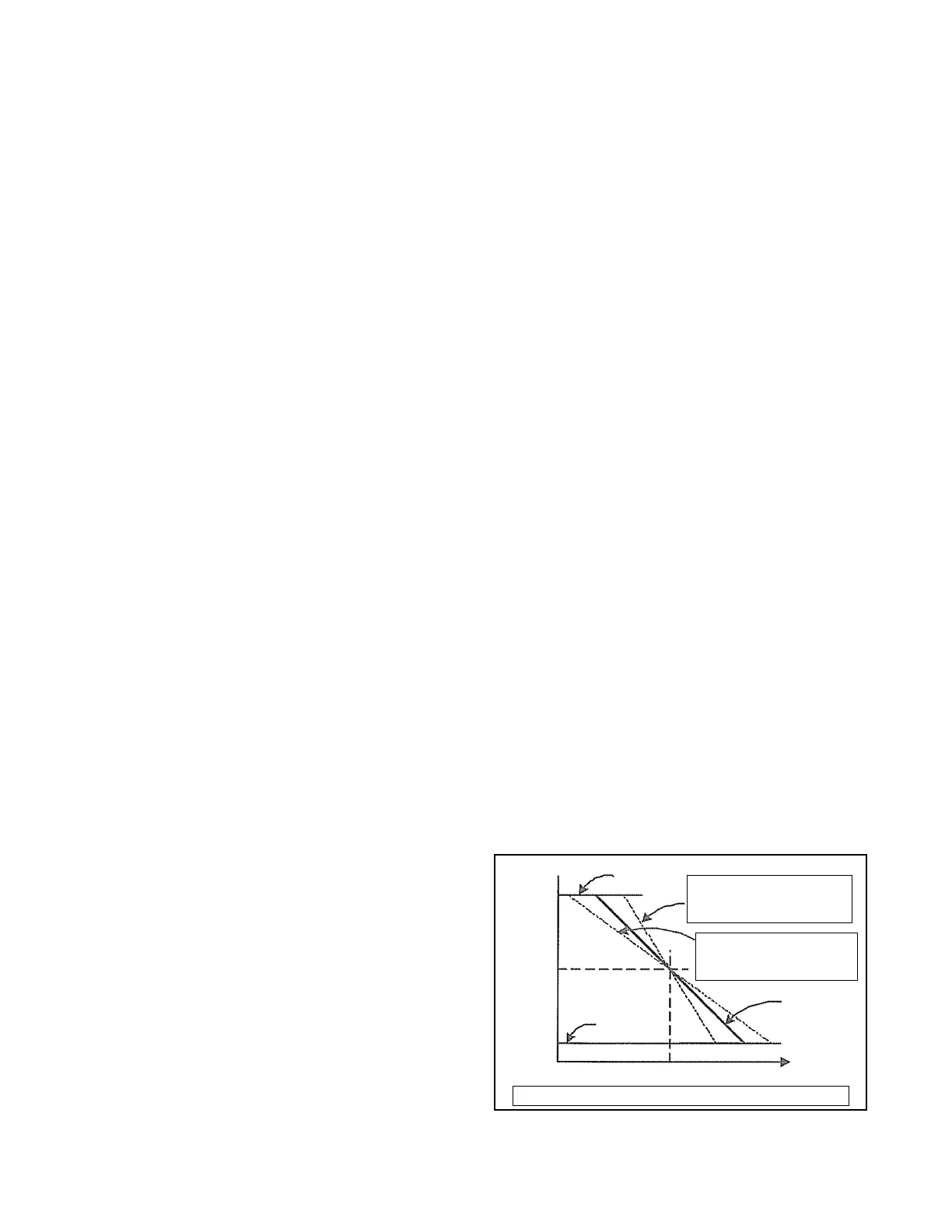

5. Proportional. Enter the value from the Governor

Parameter Summary.

A speed change creates a speed error (the

difference between the target speed and the

actual speed.) The Proportional gain controls the

size of the governor output response to a step

change in the speed error. See Figure 10-17.

TT-1399

Saturation

Each error value produce a unique controller output value.

A higher proportional value

increases output response

to a step change in error.

A lower proportional value

decreases output response

to a step change in error.

Proportional

response

0%

50%

100%

Saturation

Controller output (%)

(--) (+)0

Error (%)

Figure 10-17 Proportional Value

Loading...

Loading...