50 Section 3 Decision-Makerr 3+ Troubleshooting TP-6356 4/12

Disabling the generator set. Accidental starting can

cause severe injury or death. Before working on the

generator set or connected equipment, disable the generator

set as follows: (1) Move the generator set master switch to the

OFF position. (2) Disconnect the power to the battery charger.

(3) Remove the battery cables, negative (--) lead first.

Reconnect the negative (--) lead last when reconnecting the

battery. Follow these precautions to prevent starting of the

generator set by an automatic transfer switch, remote

start/stop switch, or engine start command from a remote

computer.

3.5.1 Fuses

To quickly check the condition of the components

mentioned in the following flowcharts, use an ohmmeter

to measure resistance between designated terminal

and ground. See Figure 3-16 and Figure 3-17. With

ohmmeter on R x 1 scale, a reading of less than 1 ohm

(continuity) indicates a potentially defective component.

Isolate the defective component and repair or replace.

Component

Connect between ground

and terminal:

Engine Gauges Connector P2, pin 1

Crank (K2 Relay) Circuit Connector P1, pin 1

Fuel/ignition Circuit Connector P1, pin 7

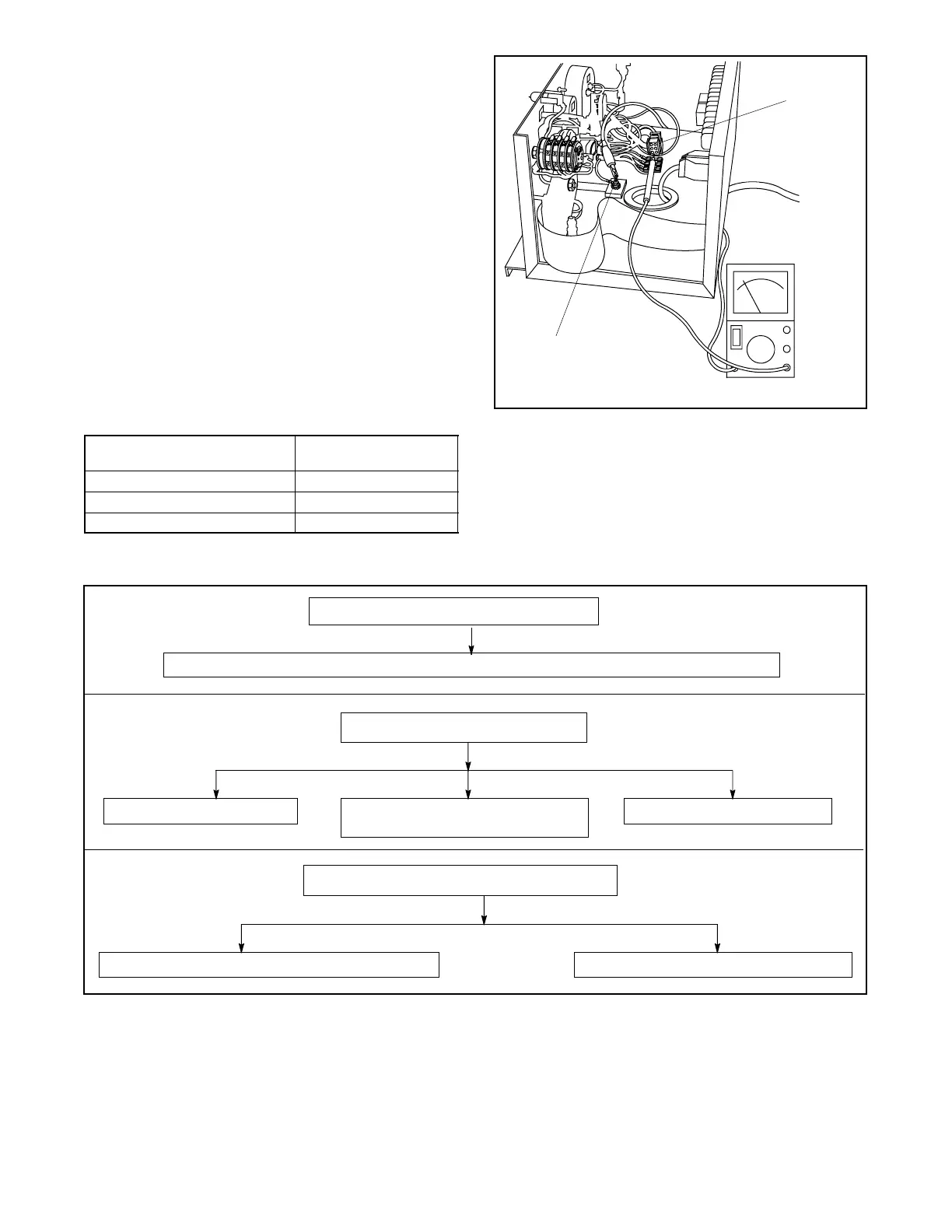

Figure 3-16 P1 and P2 Connections

3-187

Ω

1

2

1. Ground connection

2. P2 connection

Figure 3-17 Checking P1 and P2 Connections

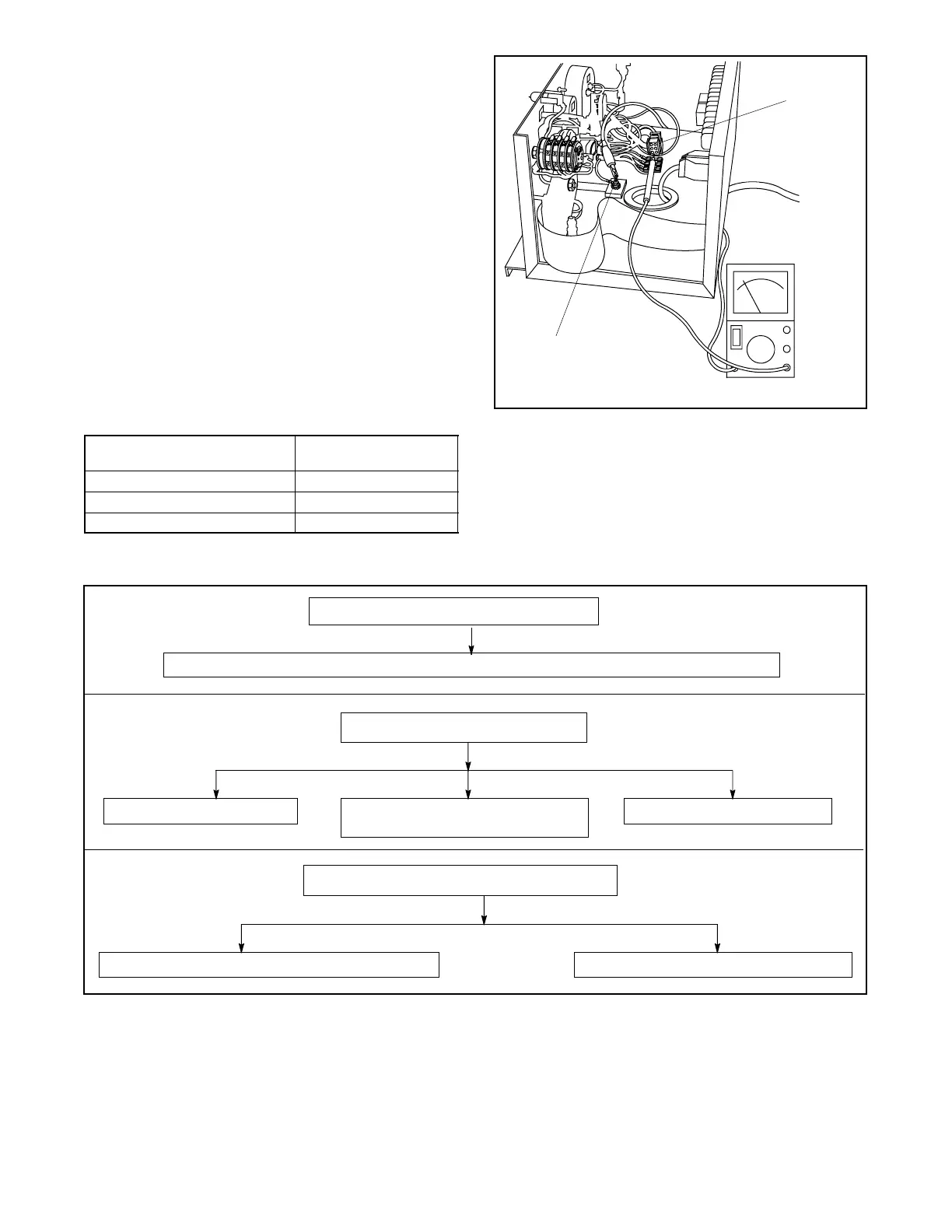

Figure 3-18 lists the possible causes of blown controller

fuses F1, F2, and F3. Replace blown fuses and resume

operation. If the fuse blows again, use the chart to

identify the faulty component(s).

Blown F1 fuse (remote annunciator: 3 amp)

Blown F2 fuse (controller: 3 amp)

Battery connections reversed Shorted DC supply to indicator panel

circuit board

Shorted controller circuit board

Blown F3 fuse (engine and accessories: 15 amp)

Defective engine electrical (wire 70) components

Defective panel lamps or engine gauges

Defective dry contact, kit, audio/visual alarm kit, and other accessories connected to TB1-42A

Figure 3-18 Checking Fuses F1, F2, and F3

Loading...

Loading...