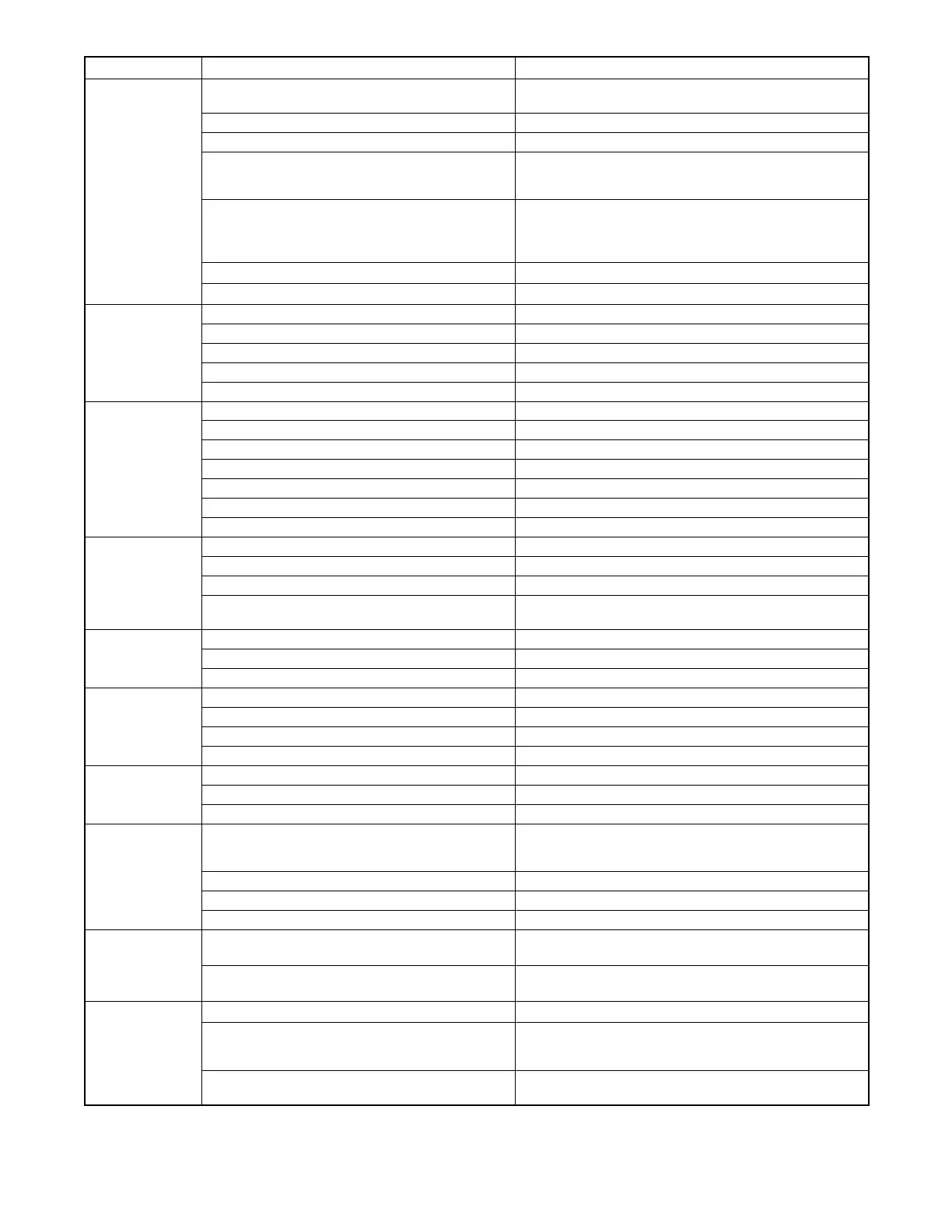

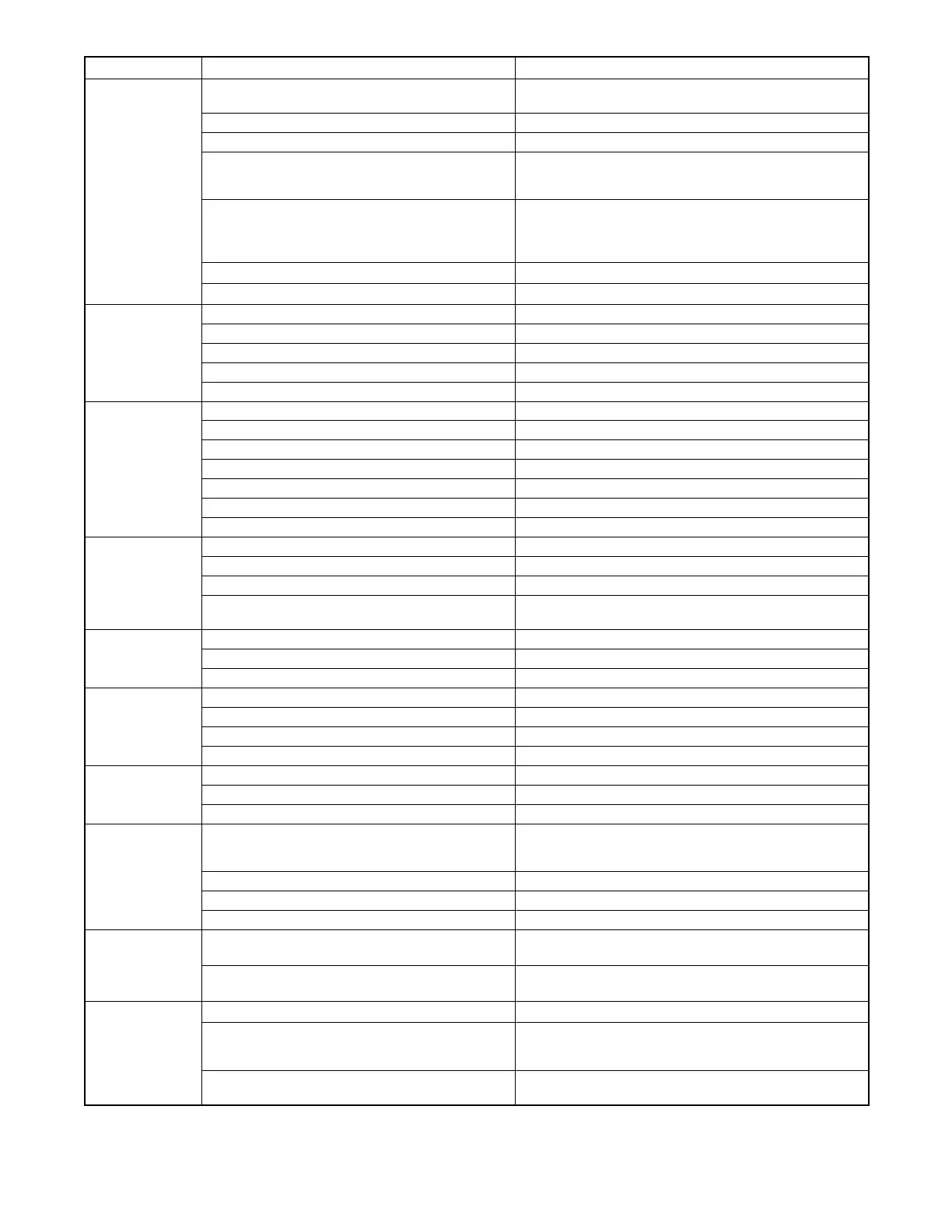

212 Section 10 Governor Adjustments TP-6356 4/12

Symptom RemedyPossible Cause

Engine does not

reach set speed

Improper Proportional, Integral, and Derivative (PID)

tuning values.

Check and adjust the PID values.

Integral value is too low or zero. Increase the integral value.

Derivative value is too low or zero (load share model). Increase the derivative value.

PID values are too low. A tuning that is too s oft can

prevent the governor from delivering the needed

actuator drive signal to reach the set speed.

Check and adjust the PID values.

PID values are too high. Tuning is too hot or

oversensitive to small speed errors causing the

governor to make large, rapid changes in actuator drive

signal, creating an average signal that is inadequate.

Decrease PID tuning values.

The integral low limit setting is too high. Return the integral low limit value to the default setting of zero.

The integral high limit setting is too low. Return the integral high limit value to the default setting of 99.

Engine takes too

long to reach the

set speed

Improper PID tuning values. Check and adjust the PID values.

Integral setting is too low. Increase the integral value.

Startup rate setting is too low. Increase the startup rate value.

Accel rate setting is too low. Increase the Accel rate value.

Speed filter setting is too high. Decrease the speed filter value.

Engine does not

track speed setting

changes

Is the LED decimal point flashing (load share model)? If yes, enter password.

Is the LED flashing fast (3 Hz) (non-load share model)? If no, check speed sensing circuit.

Is the selected set speed parameter being modified? If yes, speed setting display is unavailable during changes.

A PID value or an OVG value is too high. Decrease the PID values or OVG value.

A PID value is too low or zero. Increase the PID value.

Accel rate is set too low. Increase the Accel rate value.

Decel rate is set too low. Increase the Decel rate value.

Excessive smoke

at startup

Improper PID tuning values. Check and adjust the PID values.

The startup rate is too high. Use a lower startup rate value.

The startup limit is too high. Use a lower startup limit value.

No/low MPU speed signal present. MPU should be

2.0 VRMS minimum.

Adjust the MPU gap. Try reversing the MPU leads; otherwise,

replace the MPU.

Slow response to

load changes

Gain value set too low. Decrease the gain value.

Improper PID tuning values. Check and adjust the PID values.

Speed filter setting is too high. Decrease the speed filter value.

Engine instability

with no load

Improper PID tuning values. Check and adjust the PID values.

Speed filter setting is too low. Increase the speed filter value.

Fuel flow is restricted. Check actuator linkage.

Battery voltage is too low. Charge or replace the battery.

Engine instability

with load

Improper PID tuning values. Check and adjust the PID values.

Fuel flow is restricted. Check actuator linkage.

Battery voltage is too low. Charge or replace the battery.

Engine unable to

carry rated load

PID values may be too high, causing the governor to

overreact and make large, rapid changes in PWM duty

cycle output to the actuator.

Check and decrease the PID values.

Improper PID tuning values. Check and adjust the PID values.

Torque limit is set too low (load share model). Increase the torque limit.

Fuel flow is restricted. Check actuator linkage.

Load share does

not work (load

share model)

No/low ILS input signal present. ILS should be

2.375--2.625 VDC.

Check ILS wiring; otherwise, replace the ILS.

ILS signal wiring having electrical interference

problems.

Use shielded wiring.

Droop does not

work (load share

model)

The no load and full load values are not calibrated. Perform the droop calibration procedure.

Difference between no load and full load calibration

values is too small. Should be > 100 for best

performance.

Adjust the no load and/or full load calibration values.

Actuator linkage range too small. Modify or adjust actuator linkage to increase range of actuator

loading.

Loading...

Loading...