.

MAINTENANCE

SERVICE PROCEDURE

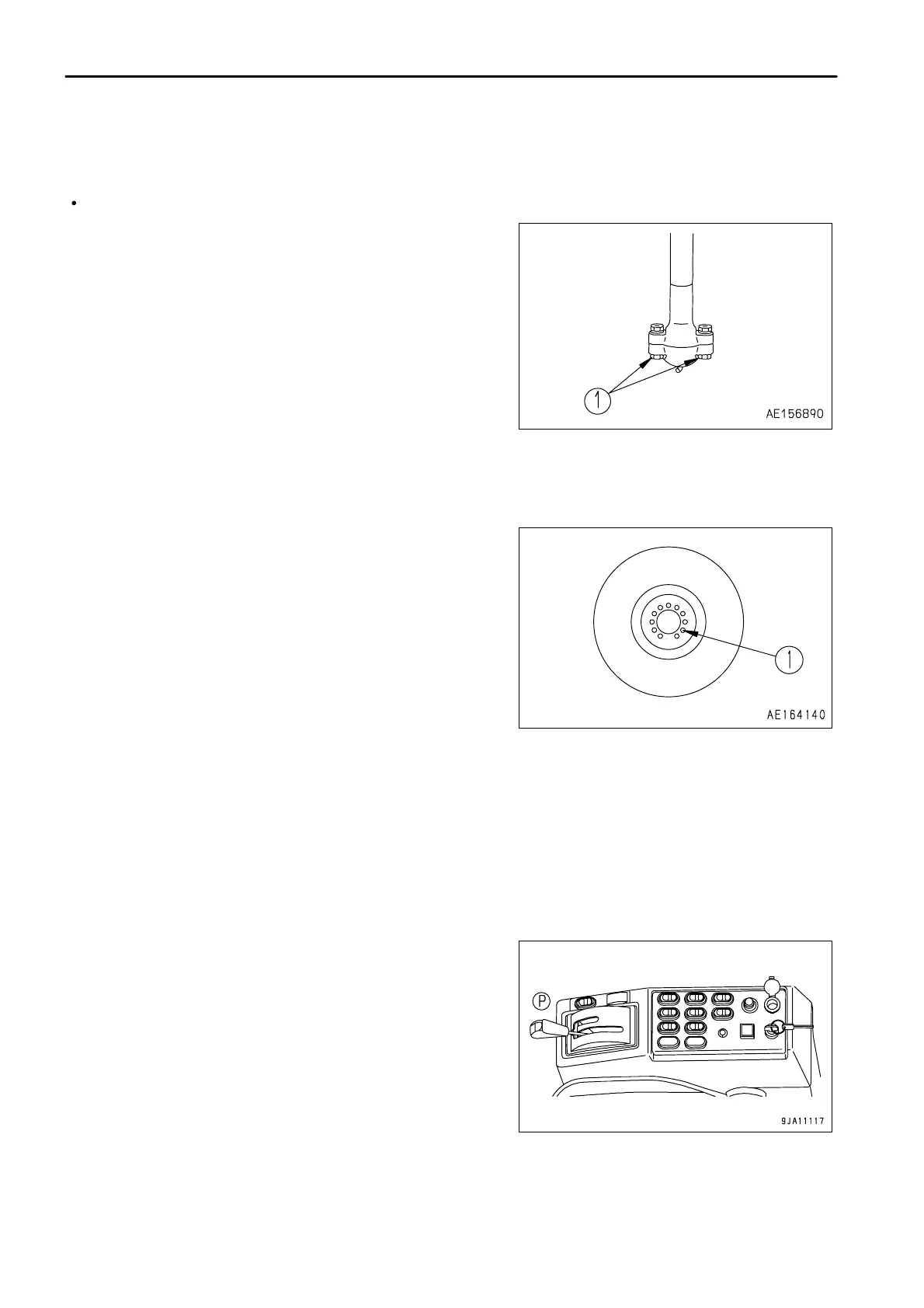

CHECK AND ADJUST BALL JOINT CLEARANCE

Check and adjust all locations with ball joints at the links of the work equipment.

Check for any play in the ball joint, and if the axial play is more than 1 mm (0.039 in), adjust as follows.

Prepare a thickness gauge

1.

Remove all the shims from the ball joint.

2.

Tighten the caps with bolts (1) to make the same clearance on

the left and right.

3.

Measure the clearance with a thickness gauge, then insert 1

shim more than this dimension, and tighten the cap.

Thickness of 1 shim: 0.2 mm (0.008 in),

0.5 mm (0.020 in)

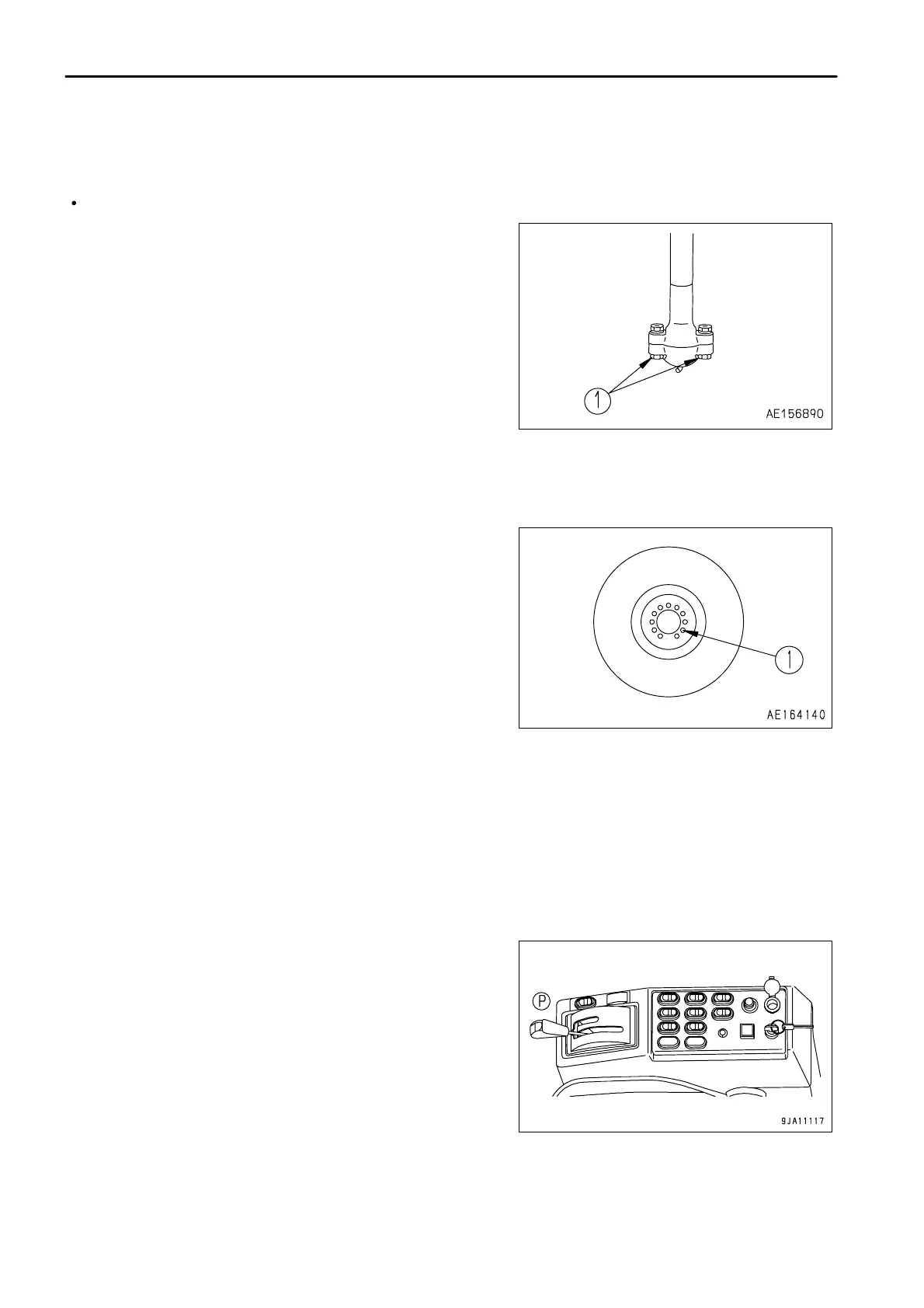

CHECK AND TIGHTEN WHEEL HUB NUT AND HUB BOLT

NOTICE

Loose wheel hub nuts and hub bolts (1) will result in shortened life of tires

or other troubles.

1.

Carefully check for loose bolts (1).

When checking for loose bolts (1), always turn the bolts (1) in

the tightening direction to check.

Tightening torque: 610 to 765 Nm

(62.5 to 78.0 kgm , 452.1 to 564.2 lbft)

2.

If a hub bolt is broken, replace all the hub bolts.

CHECKING WHEEL RIM, LOCK RING AND SIDE RING FOR CORROSION AND WEAR

If the wheel rim, lock ring and side ring are heavily corroded, ask the tire manufacturer or your Komatsu distributor

for inspection.

CHECK PARKING BRAKE

1.

Set the machine on a dry downhill slope, set the gearshift lever

to the P (Parking) position, and check if the parking brake can

hold the machine in position.

2.

If any problem is found, please contact your Komatsu

distributor.

4 - 56

Loading...

Loading...