.

MAINTENANCE

SERVICE PROCEDURE

7. When installing, tighten until the packing surface contacts the seal surface of the filter holder, then tighten it 3/4

of a turn.

If the filter cartridge is tightened too far, the packing will be damaged and this will lead to leakage of fuel. If the

filter cartridge is too loose, fuel will also leak from the packing, so always tighten the correct amount.

8.

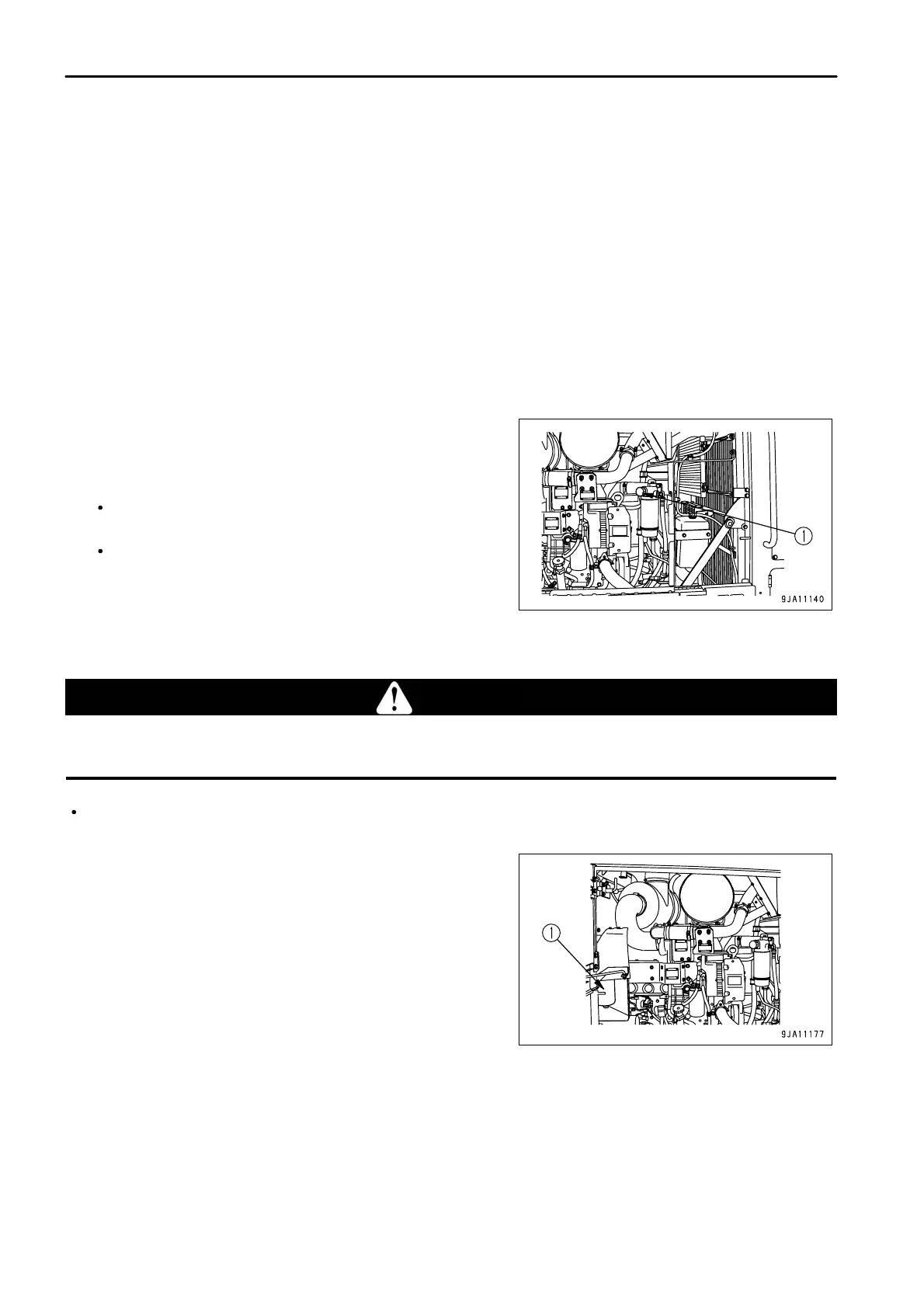

After completing replacement of filter cartridge (1), bleed the air

from the system. For details, see "PROCEDURE FOR BLEEDING AIR (PAGE 4-64)".

9. After completing the air bleeding, start the engine and check that there is no leakage of fuel from the filter seal

surface. If there is any leakage, check the tightening condition of the filter cartridge. If there is still fuel leakage,

repeat Steps 1 to 3 to remove the filter cartridge, then check the packing surface for damage or embedded dirt.

If any damage or embedded dirt is found, replace the cartridge with a new part and repeat Steps 4 to 8 to install

it.

PROCEDURE FOR BLEEDING AIR

1.

Fill the fuel tank with fuel.

2.

Open the engine side cover on the left side of the machine.

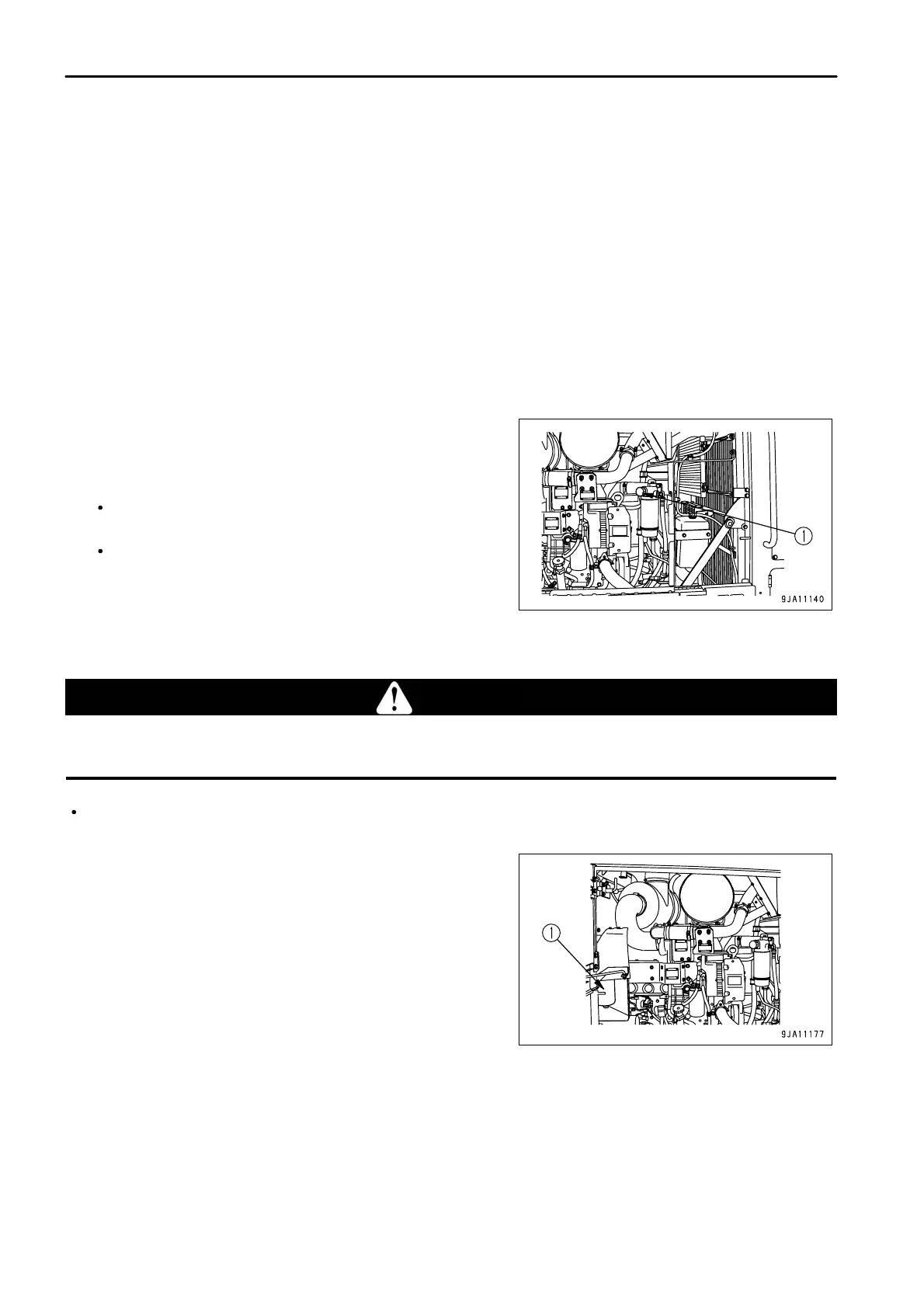

3. Loosen and pull out feed pump knob (1) and move it forward

and backward.

The plug on the side surface of the fuel prefilter head does

not need to be removed.

Keep moving knob (1) until it becomes heavy.

4.

After bleeding air, push in and tighten knob (1).

REPLACE TRANSMISSION OIL FILTER CARTRIDGE

WARNING

The parts and oil are at high temperature immediately after the engine is stopped, and may cause burns. Wait for the temperature

to go down before starting the work.

Prepare a ring wrench

1. Set the container under the filter cartridge to catch the drained

oil.

2.

Using the ring wrench, turn filter cartridge (1) to the left to

remove it.

3.

Clean the filter holder, coat the seal surface of the new filter

cartridge thinly with clean engine oil, then install to the filter

holder.

Tightening torque: 49 to 59 Nm (5 to 6 kgm, 36.2 to 43.4 lbft)

4 - 64

Loading...

Loading...