METHOD FOR CHECKING REAR BRAKE DISC WEAR AMOUNT

WARNING

• Immediately after the engine is stopped, its parts and oil are still very hot and may cause burn in-

jury.

Wait for the temperature to go down, and then start the work.

• Be sure to check the wear amount of the brake disc.

If the wear amount of the disc has exceeded the wear limit, the machine cannot stop at the specific

distance due to the prolonged braking distance, and a serious personal injury or death may result.

1.

Stop the machine on a flat place.

2.

Set the parking brake switch to “PARKING” position.

Check this time that other brakes are not applied.

3.

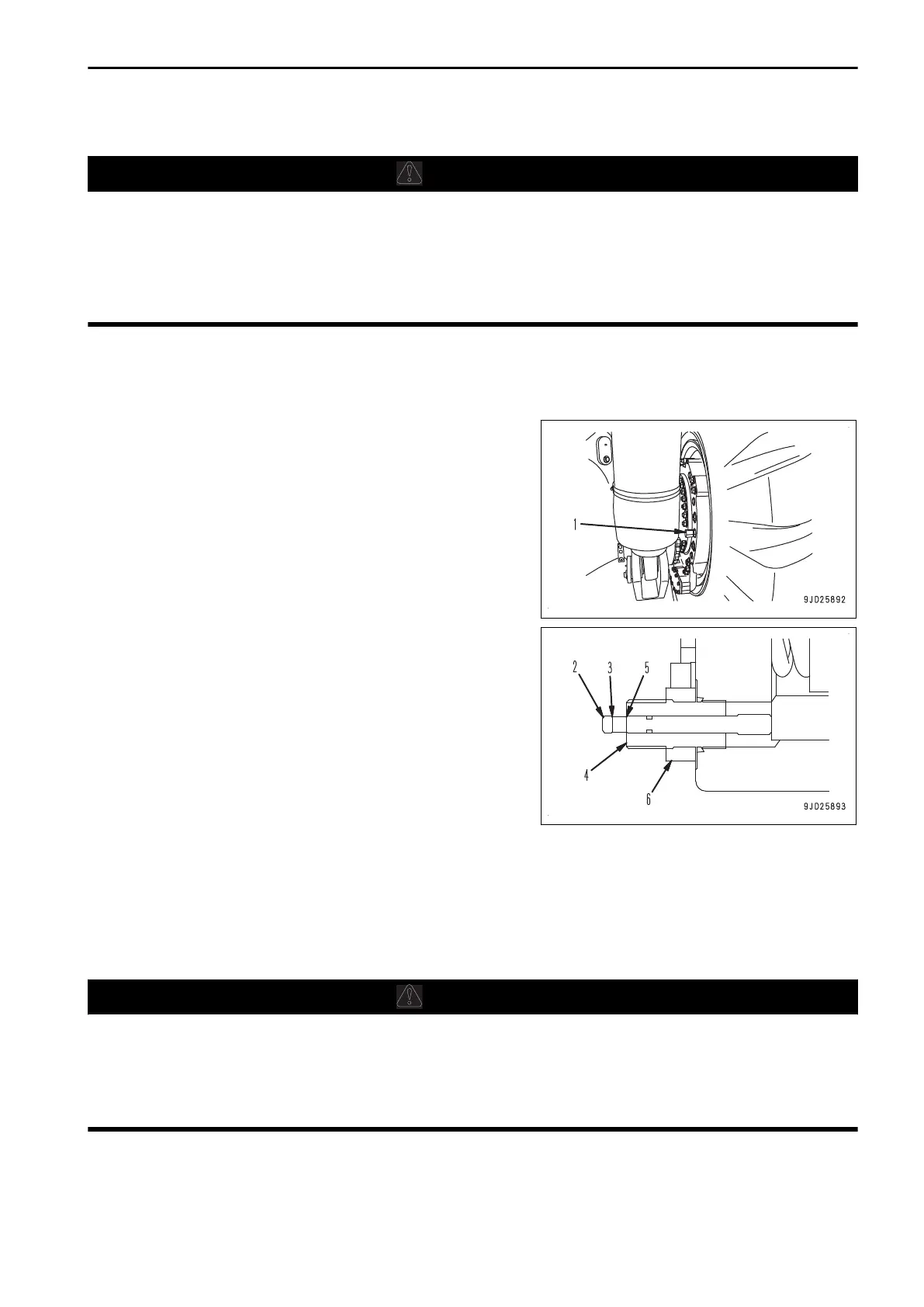

Remove the cap nut (1).

4.

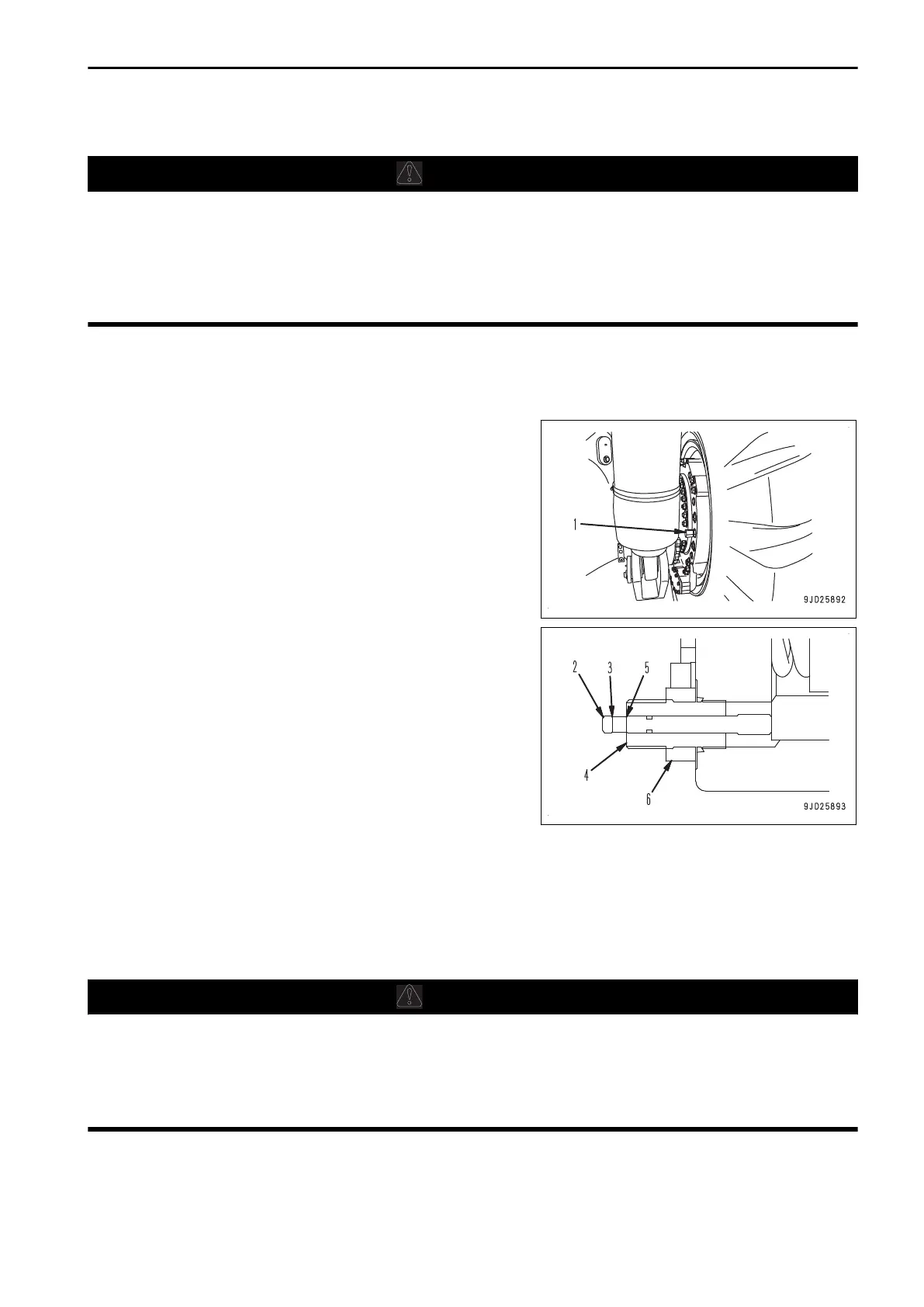

Push in the rod (2) of the gauge until it touches the piston.

Do not depress the brake pedal this time.

If the slit (3) of rod (2) enters beyond the guide end face

(4), it means that the disc has reached the wear limit.

Ask your Komatsu distributor for inspection and mainte-

nance in such case.

5.

Install the cap nut (1) which is removed in the step 3.

Tightening torque: 128 to 186 Nm {13 to 19 kgm}

REMARK

• The position of the guide has been adjusted so that the slit (5) matches the end face of guide (4) for a new

machine. Therefore, do not loosen the lock nut (6) except when replacing the disc.

• If the rod is pushed in when the engine is running, the rod will be pushed back by the brake cooling oil pres-

sure, so the engine should be stopped when pushing the rod.

METHOD FOR COLLECTING LEAKED OIL FROM FLOATING SEAL

WARNING

• Immediately after the engine is stopped, its parts and oil are still very hot and may cause burn in-

jury.

Wait for the temperature to go down, and then start the work.

• If there is remaining pressure inside the case, the oil or plug may jump out.

Turn the plug slowly to release the pressure, then remove it carefully.

REMARK

Whenever oil flows out of the overflow hose, collect the oil.

MAINTENANCE MAINTENANCE PROCEDURE

4-59

Loading...

Loading...