10.

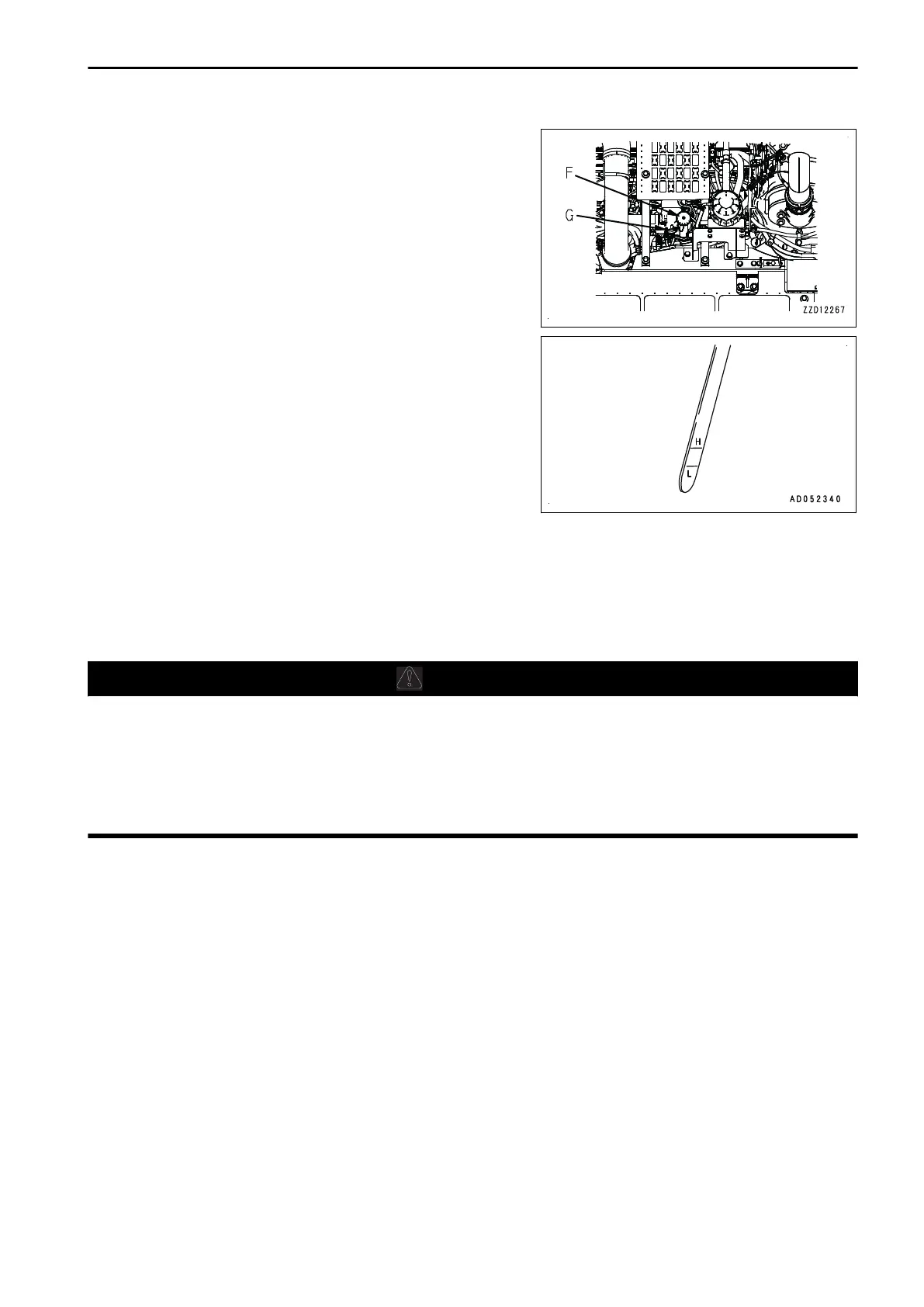

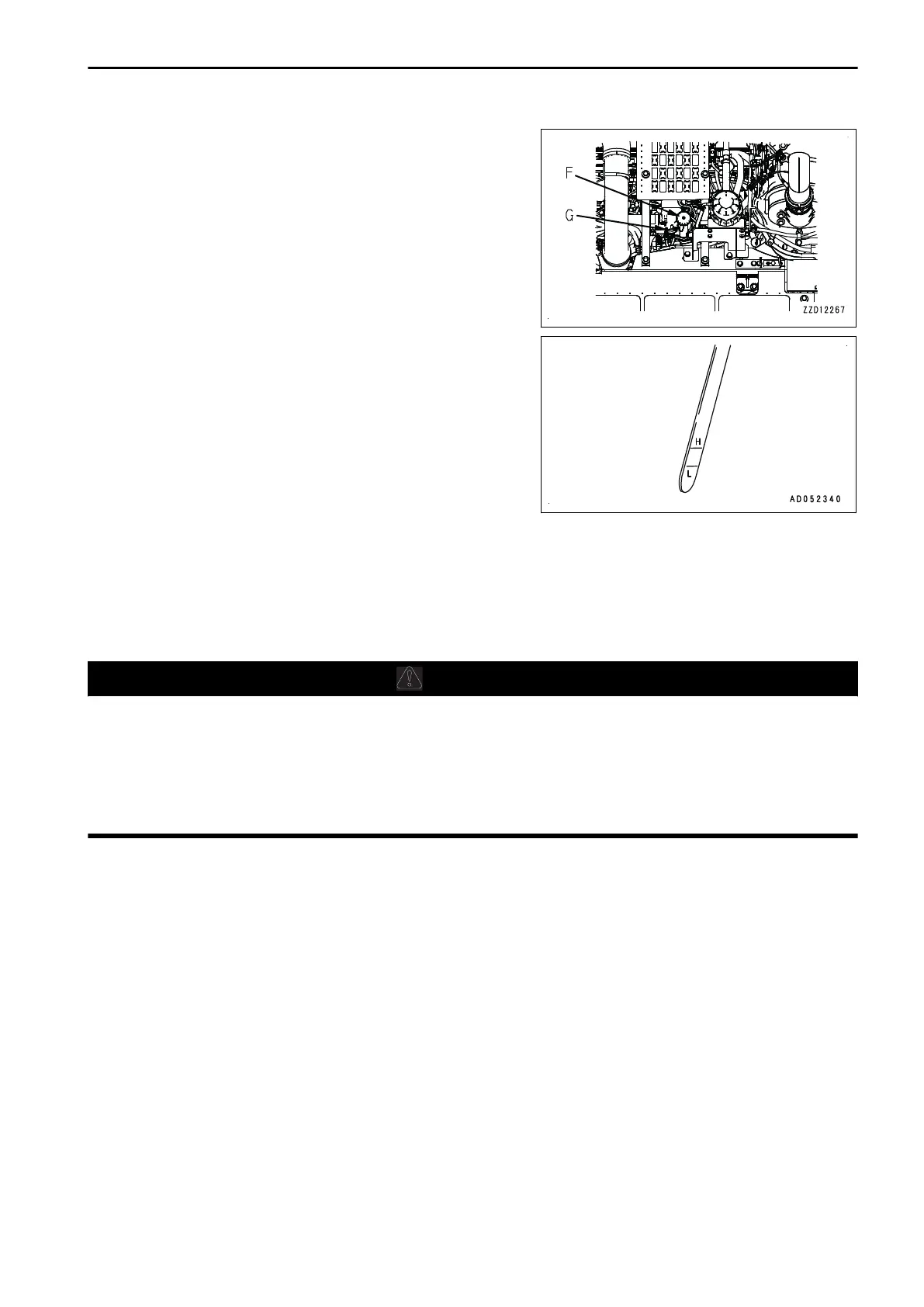

After replacing the filter cartridge, open the engine hood

and fill with engine oil through oil filler port (F) to the mid-

point between H and L marks on dipstick (G).

11.

Run the engine at idle for a time, then stop the engine and

check that the oil level is between H and L marks on the

dipstick. For details, see “METHOD FOR CHECKING OIL

LEVEL IN ENGINE OIL PAN, ADDING OIL (3-149)”.

12.

Remove hose (2).

13.

Install cover (1).

REMARK

When the ambient temperature is low, water or emulsified matter may stick to the dipstick, oil filler cap, etc. or

the drained oil may be milky white because of water vapor in the blowby gas. However, if the coolant level is

normal, it is not a problem.

There is no problem even if the emulsified matter cannot be removed completely after changing oil.

METHOD FOR REPLACING FUEL PREFILTER CARTRIDGE

WARNING

• After the engine stops, all parts are still very hot, so do not replace the filter immediately. Wait until

all of parts cool down before starting the work.

• High pressure is generated inside the engine fuel piping system when the engine is running.

When replacing the filter, wait for at least 30 seconds after stopping the engine to let the internal

pressure go down before replacing the filter.

• Do not bring any open flame close.

NOTICE

• Komatsu genuine fuel filter cartridges use a special filter that has highly efficient filtering ability.

When replacing parts, Komatsu recommends using Komatsu genuine parts.

• The common rail fuel injection system used on this machine consists of more precise parts than

those in the conventional injection pump and nozzles. If any cartridge other than a Komatsu genu-

ine filter cartridge is used, dust or dirt may get in and cause problems with the injection system.

Never use a substitute.

• When performing inspection and maintenance of the fuel system, be careful not to let any dirt or

dust get in, more than ever before. If dust sticks to the fuel system, wash it off thoroughly with fuel.

Items to be prepared

• Container to receive the drained fuel

• Filter wrench

MAINTENANCE MAINTENANCE PROCEDURE

4-49

Loading...

Loading...