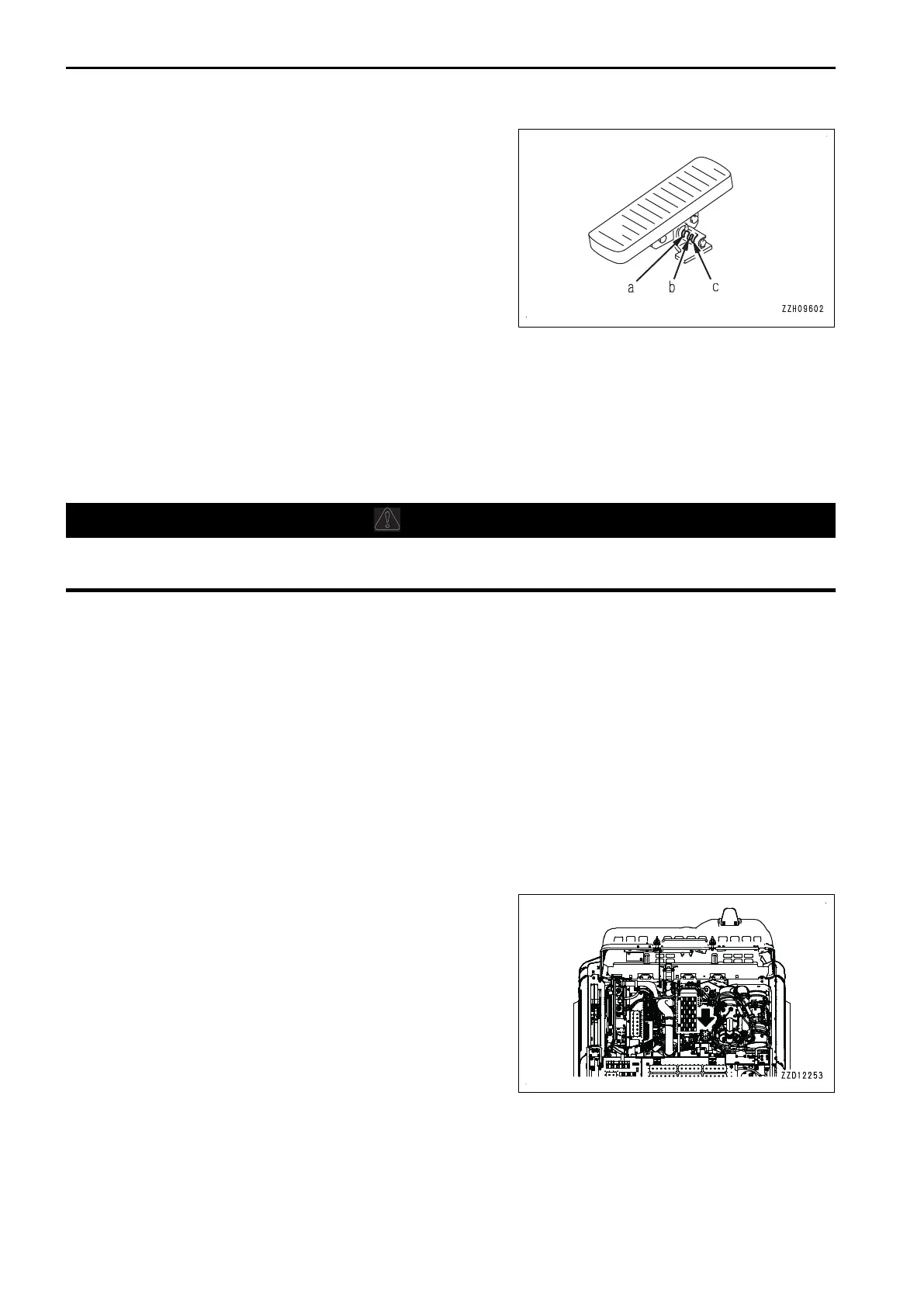

If an attachment is installed, set the lock pin to position (a)

so that you cannot operate the attachment control pedal.

METHOD FOR CHECKING ALTERNATOR

Ask your Komatsu distributor to have the alternator checked.

If the engine is started frequently, have this inspection performed every 1000 hours.

METHOD FOR CHECKING AND ADJUSTING ENGINE VALVE CLEARANCE

Special tools are necessary for inspection and maintenance. Ask your Komatsu distributor to perform this work.

METHOD FOR REPLACING KCCV FILTER ELEMENT

WARNING

After the engine has been operated, all of the parts are still very hot. Do not replace the filter element

immediately. Wait until all of parts cool down before starting the work.

NOTICE

• If the engine is operated without the filter element, the turbocharger and aftercooler become dirty

and their performance will lower and that can cause engine problems such as overrun caused by

suction of oil. Therefore, do not start the engine without the filter element.

• The filter element cannot be flushed. Flushing or regenerating of the filter element will degrade per-

formance of the filter. As a result, the turbocharger and aftercooler become dirty and the perform-

ance lowers or the crankcase pressure increases. Never reuse the filter element since it can cause

an engine failure.

• After the filter element is replaced, if KCCV is not assembled correctly, oil or blowby gas may leak.

Replace the filter element in the correct procedure.

Items to be prepared

• Container to receive the drained fuel

• Special wrench for KCCV

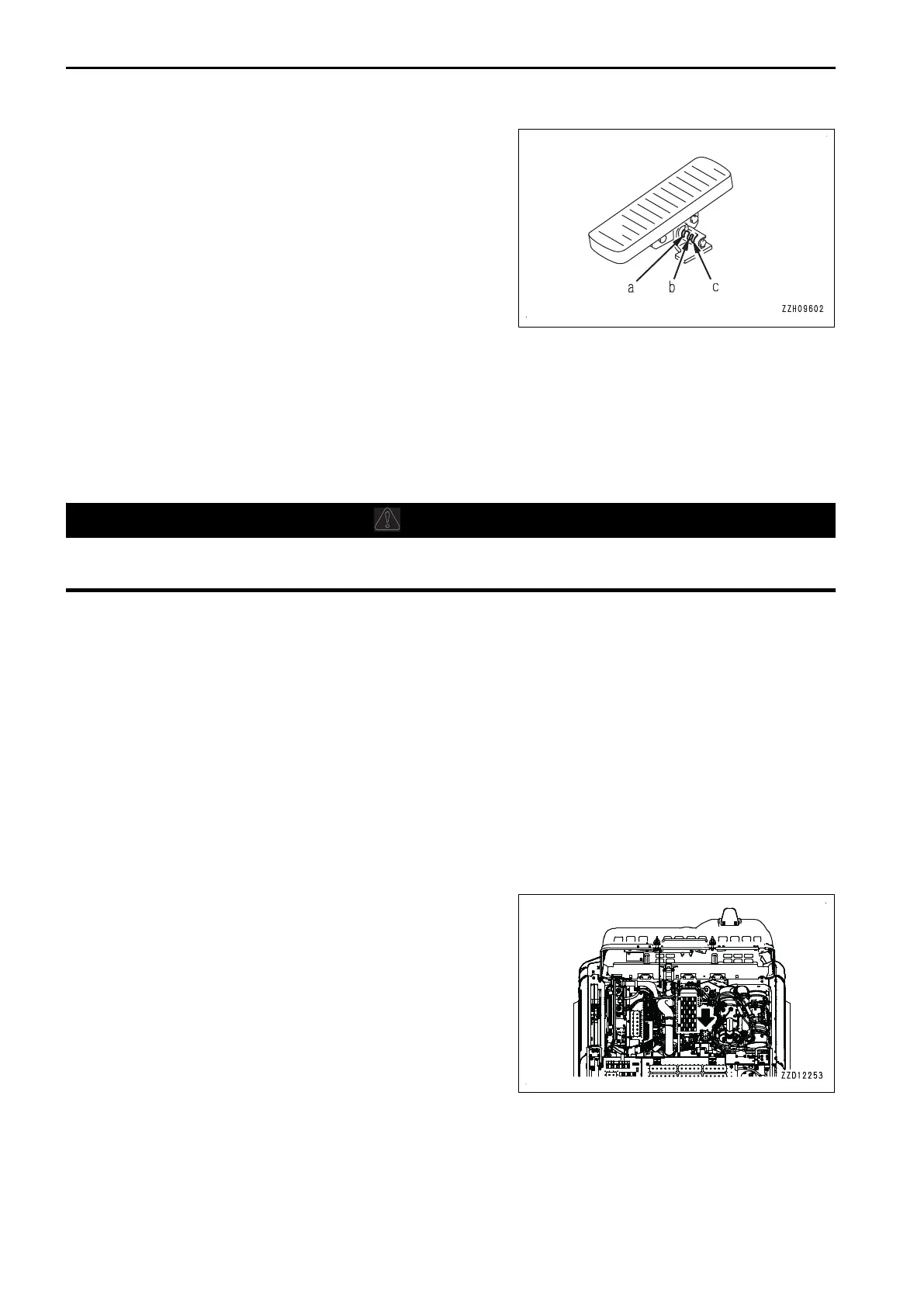

The KCCV ventilator is located in the positions shown in the

figure.

MAINTENANCE PROCEDURE MAINTENANCE

4-70

Loading...

Loading...